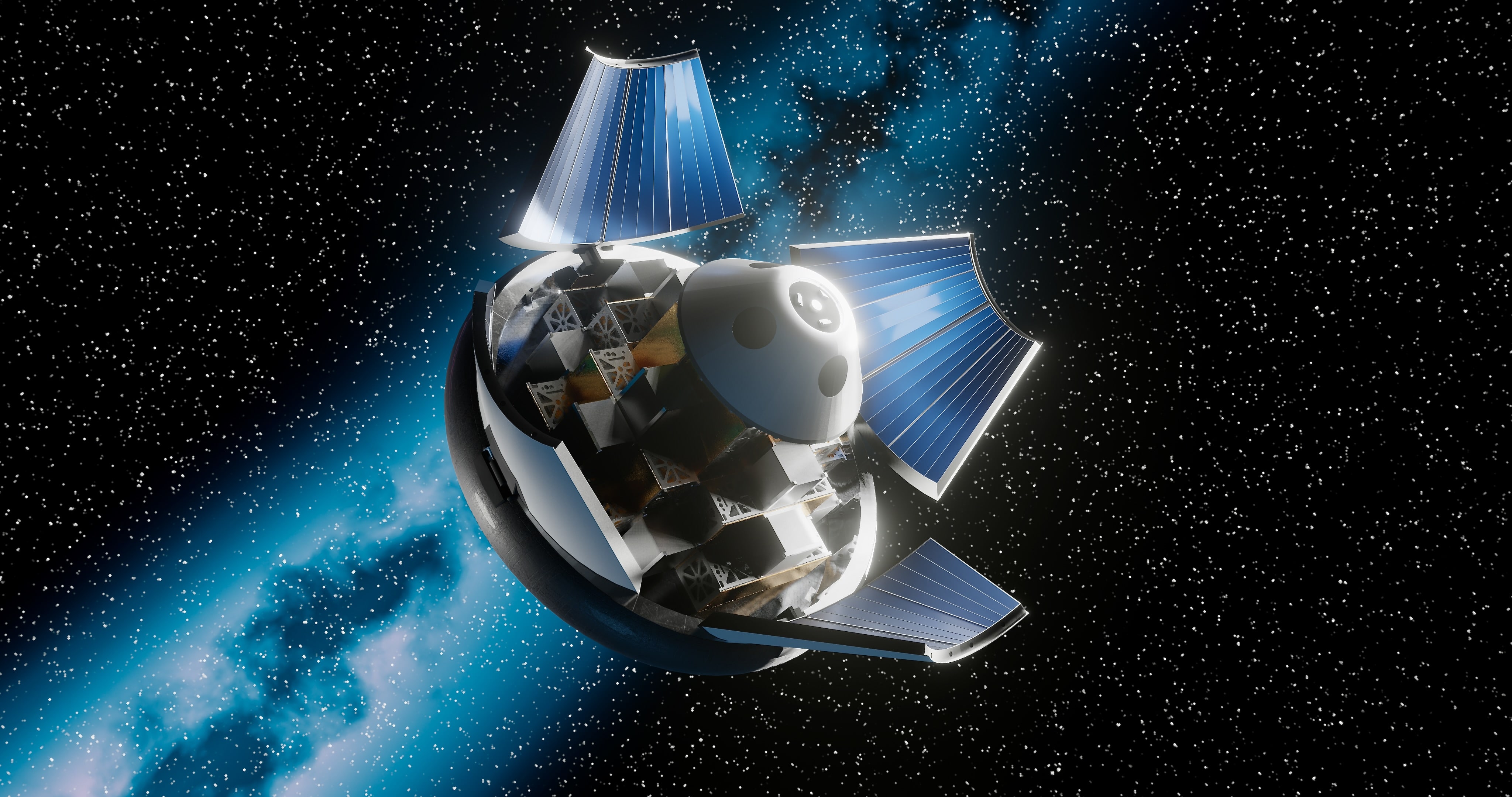

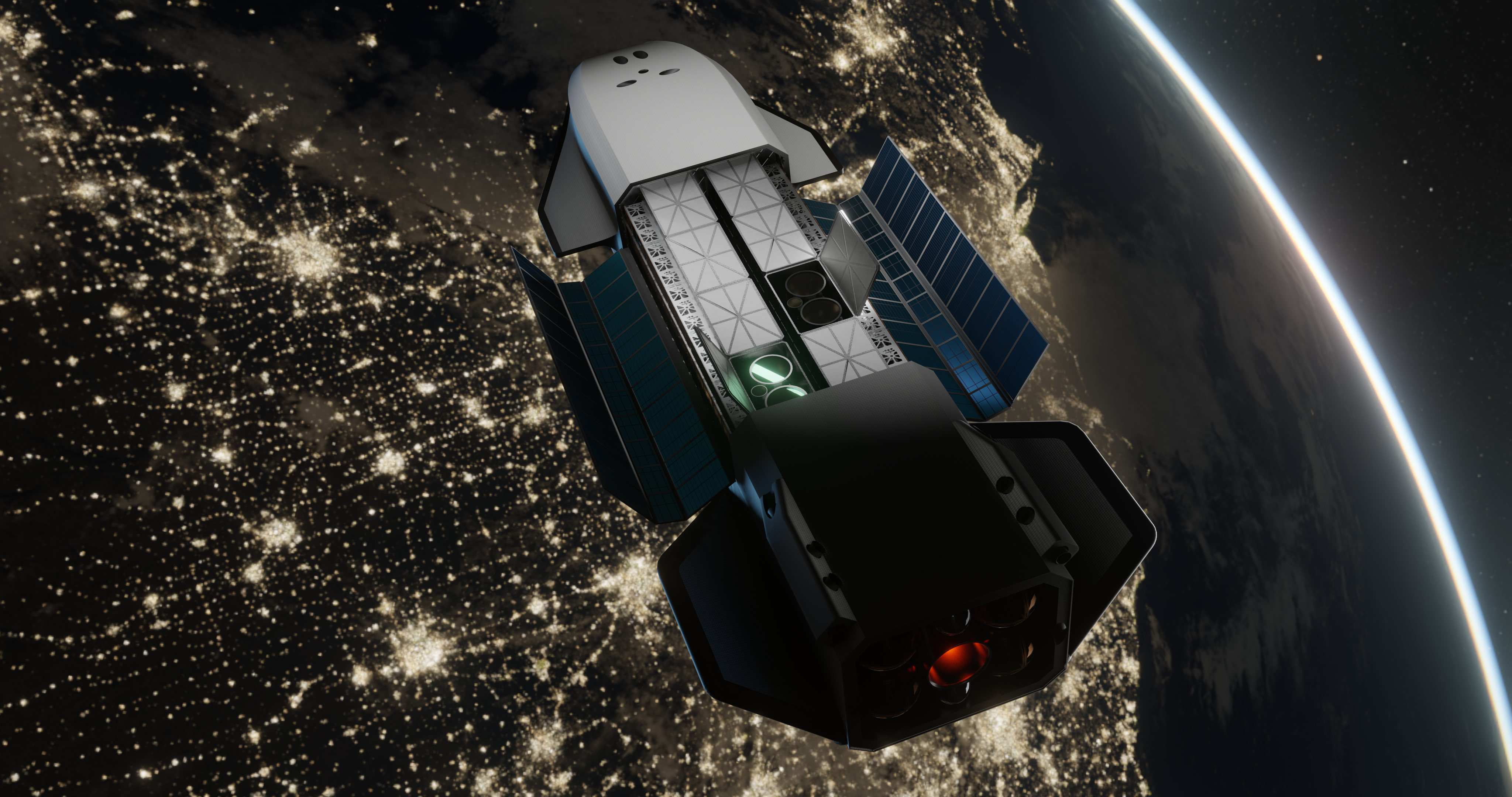

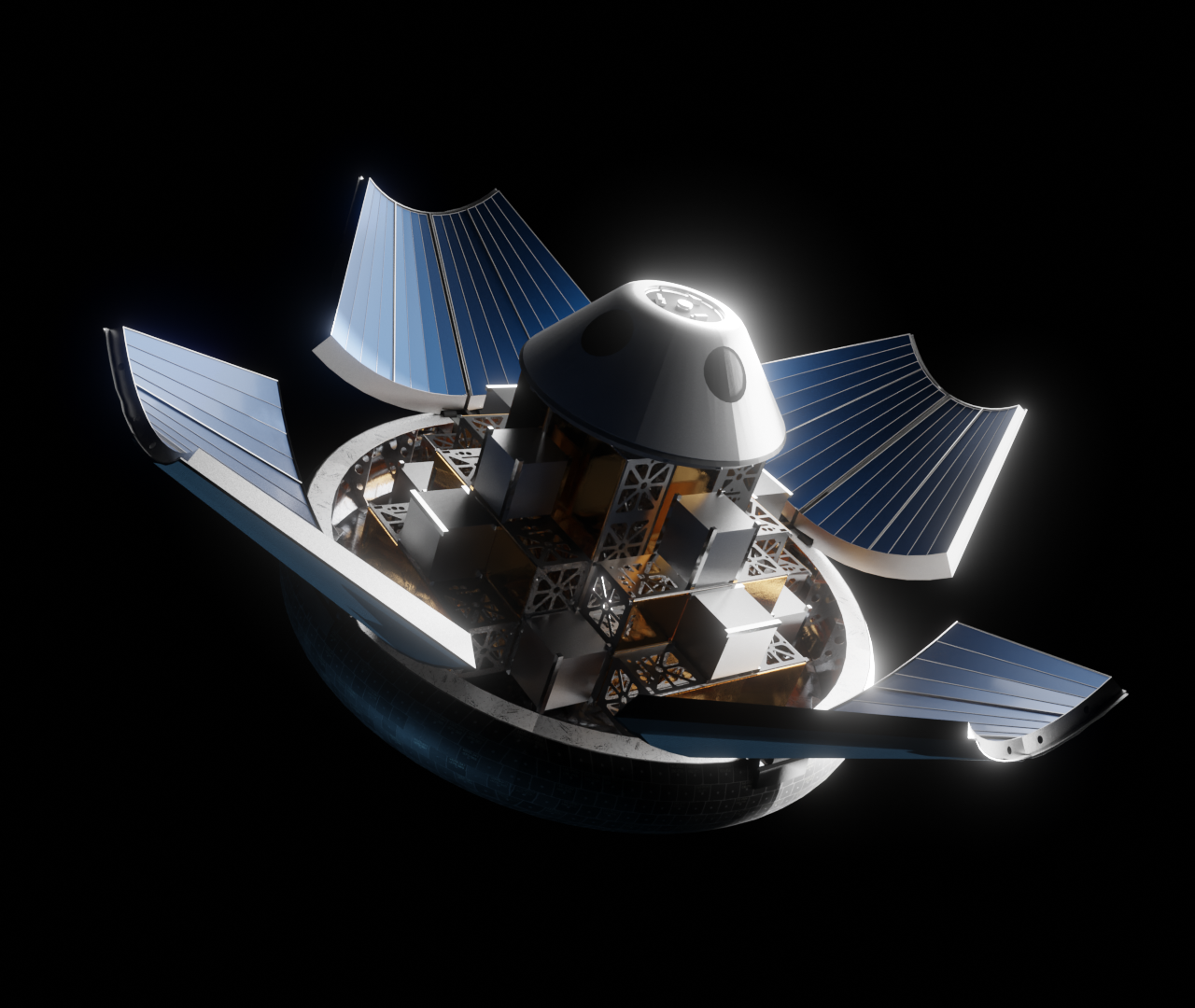

Nazare Space Capsule

Reusable autonomous space cargo

2022-2023

Follow Reenter Space for the latest news at https://reenter.space

Nazare is a name inspired by the mythical giant waves of the Nazare canyon in Portugal. They are the product of uniquely focused energy from the underwater ridge, and surfers from all over the world travel to surf these dangerous and mighty monsters.

The Nazare Spacecraft, thus, begins as mighty challenger from the Portuguese industry, to the world.

The Downmass challenge

Access to returnable space cargo has been uniquely reserved to the Dragon Capsule as of 2022. This makes missions that require downmass more expensive and rare.

The solution

An unique design, capable of flying a variety of equipment and mission types.

"... even with all the diversity among these [launch] companies, one thing seems to be being overlooked. What about downmass?"

Dylan Taylor

Chairman & CEO, Voyager Space

Dylan Taylor

Chairman & CEO, Voyager Space

Fully reusable space platform

Besides returning from space, Nazare reflies all of its systems, saving cost and increasing response speed.

The perfect dedicated platform for:

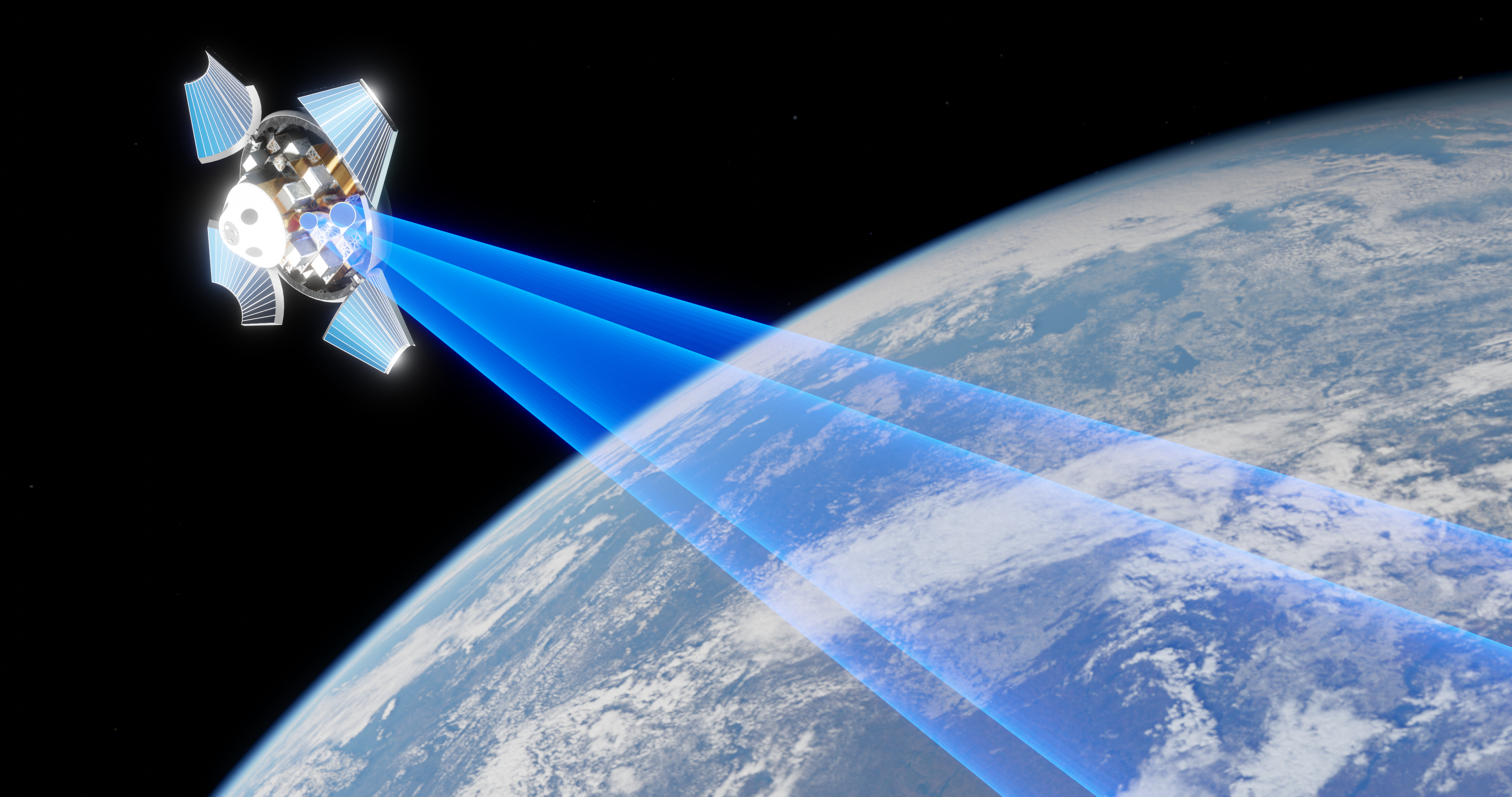

︎ Earth observation

︎ Microgravity experiments

︎ In-space manufacturing

︎ Recovering space assets and products

Besides returning from space, Nazare reflies all of its systems, saving cost and increasing response speed.

The perfect dedicated platform for:

︎ Earth observation

︎ Microgravity experiments

︎ In-space manufacturing

︎ Recovering space assets and products

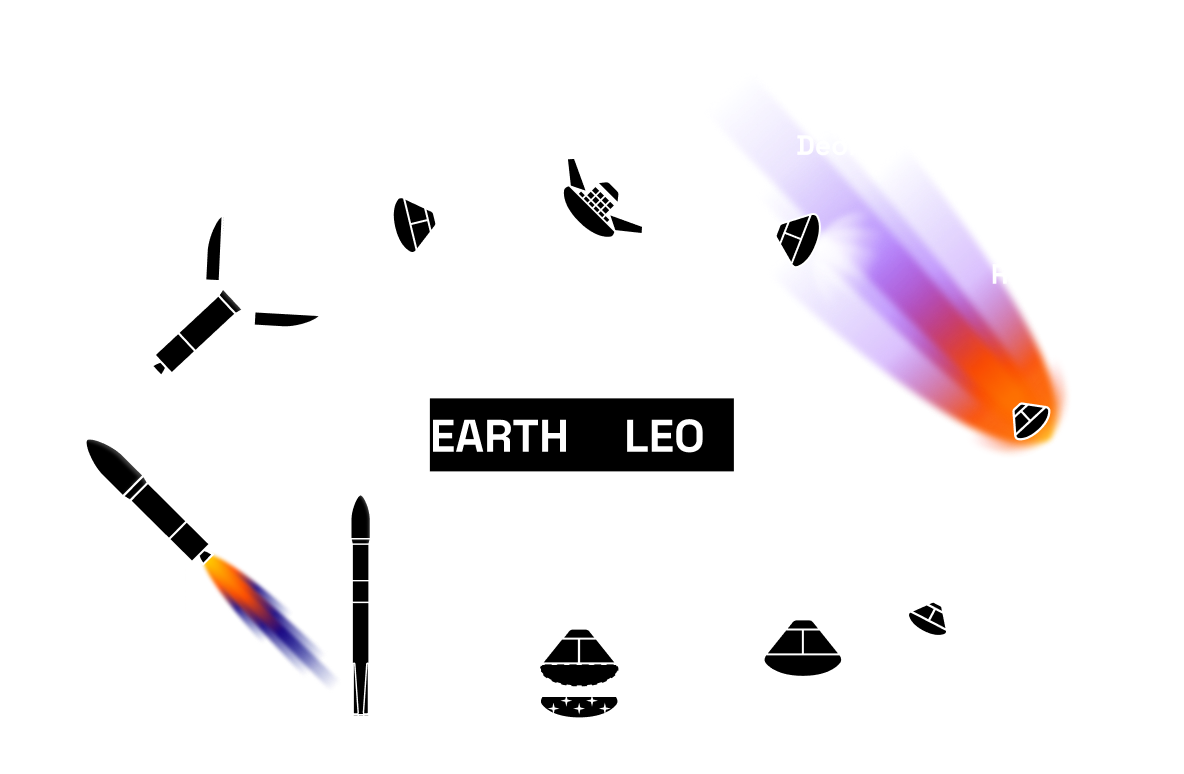

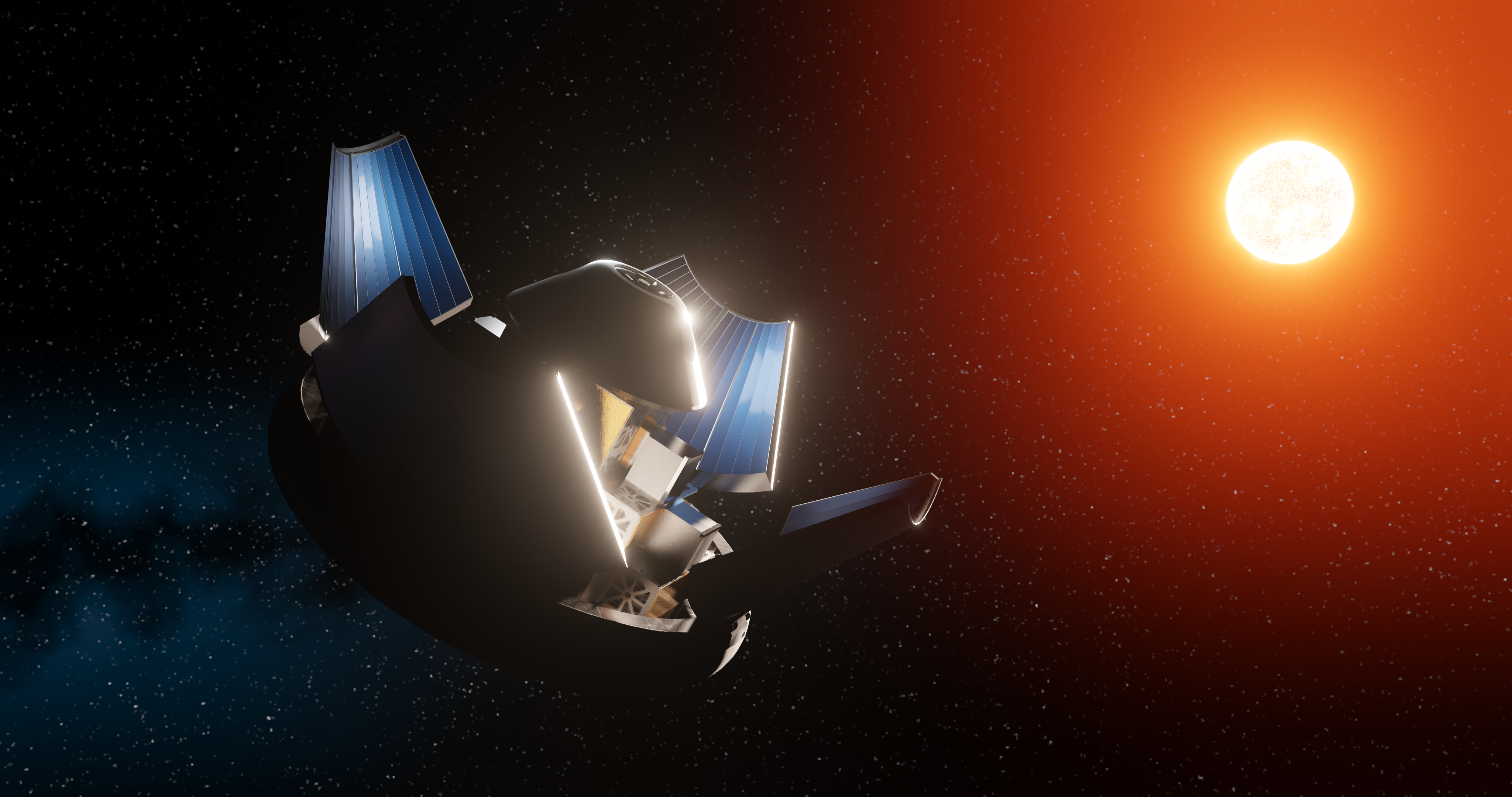

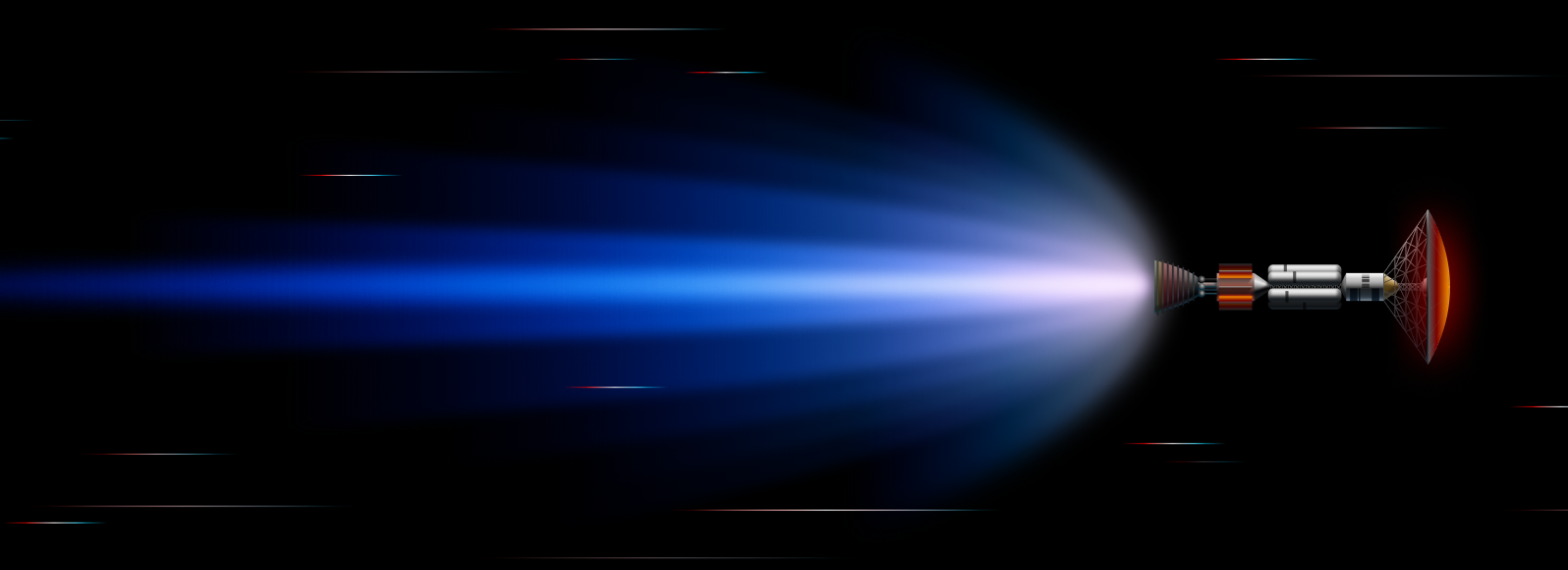

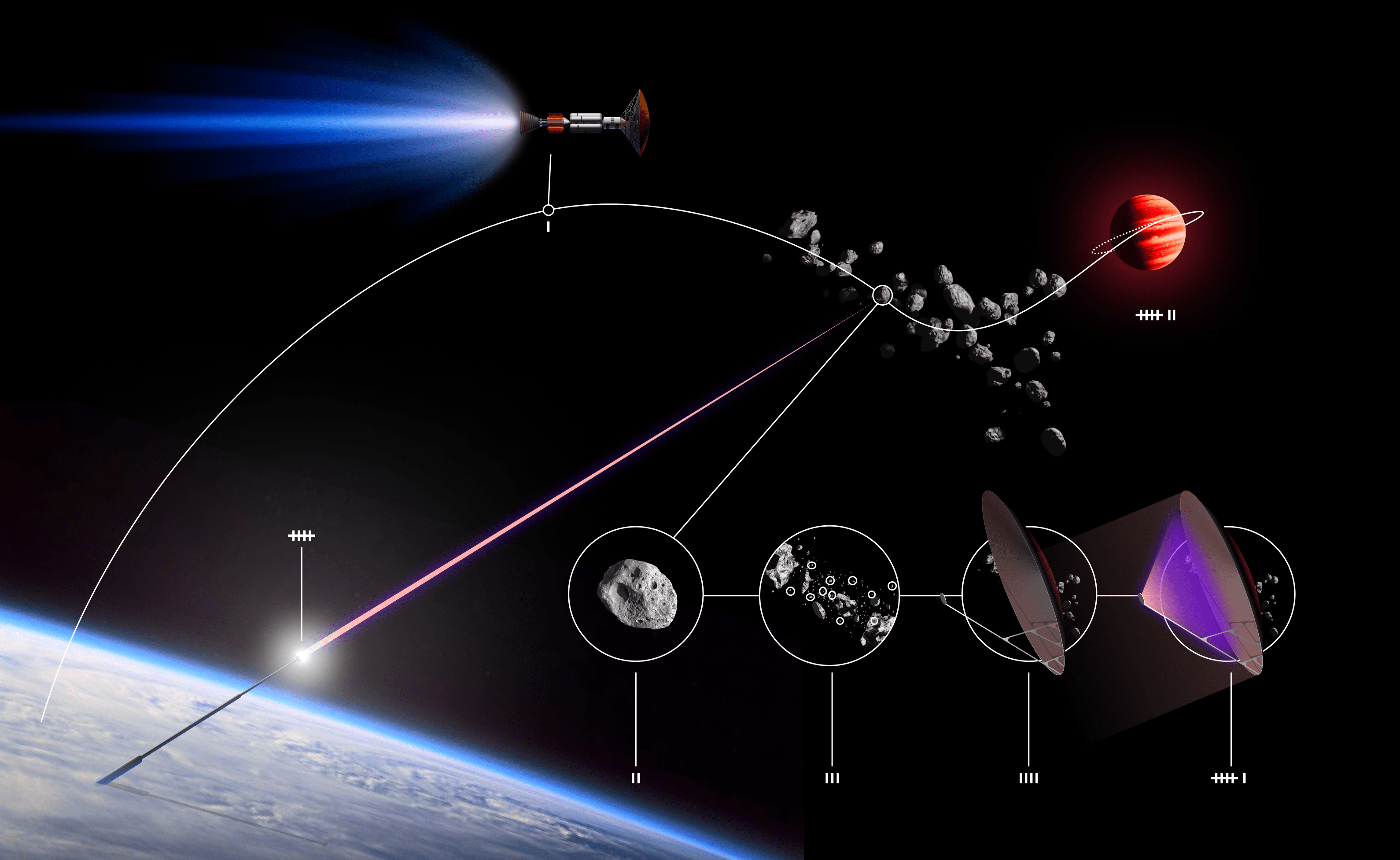

A concept of operations reminescent of the space shuttle

With Nazare, access to space changes entirely into a reusable logistical system. With vehicles capable of being deployed from anytype of

Made for the industries of the future

Main advantages of Nazare

Recovering mass from space is nothing new. In fact every crewed mission did this in the past. However, landing precisely, using cheap materials, and being easy to refurbish have always been hard problems to solve.

Nazare addresses these problems in an unique way.

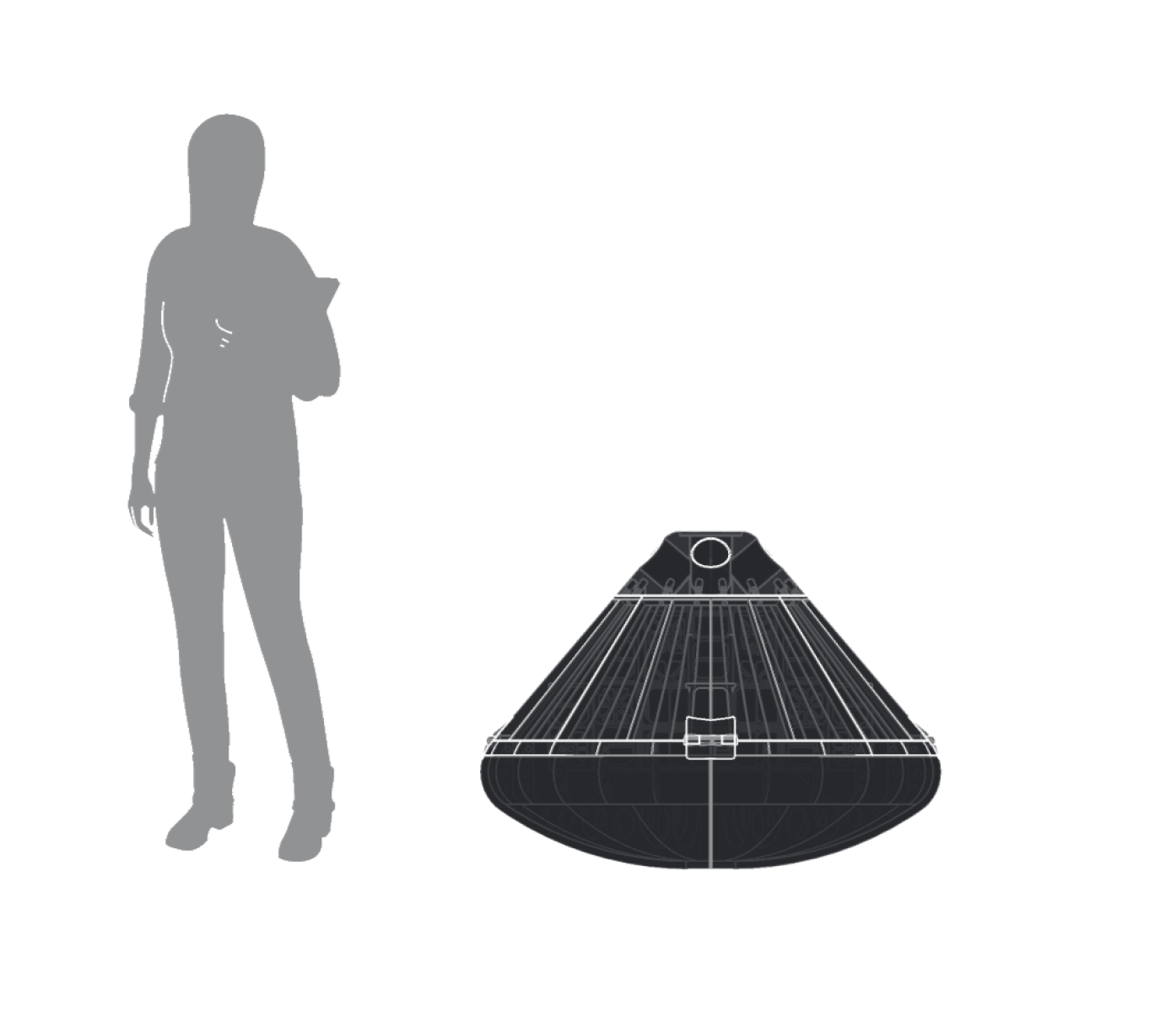

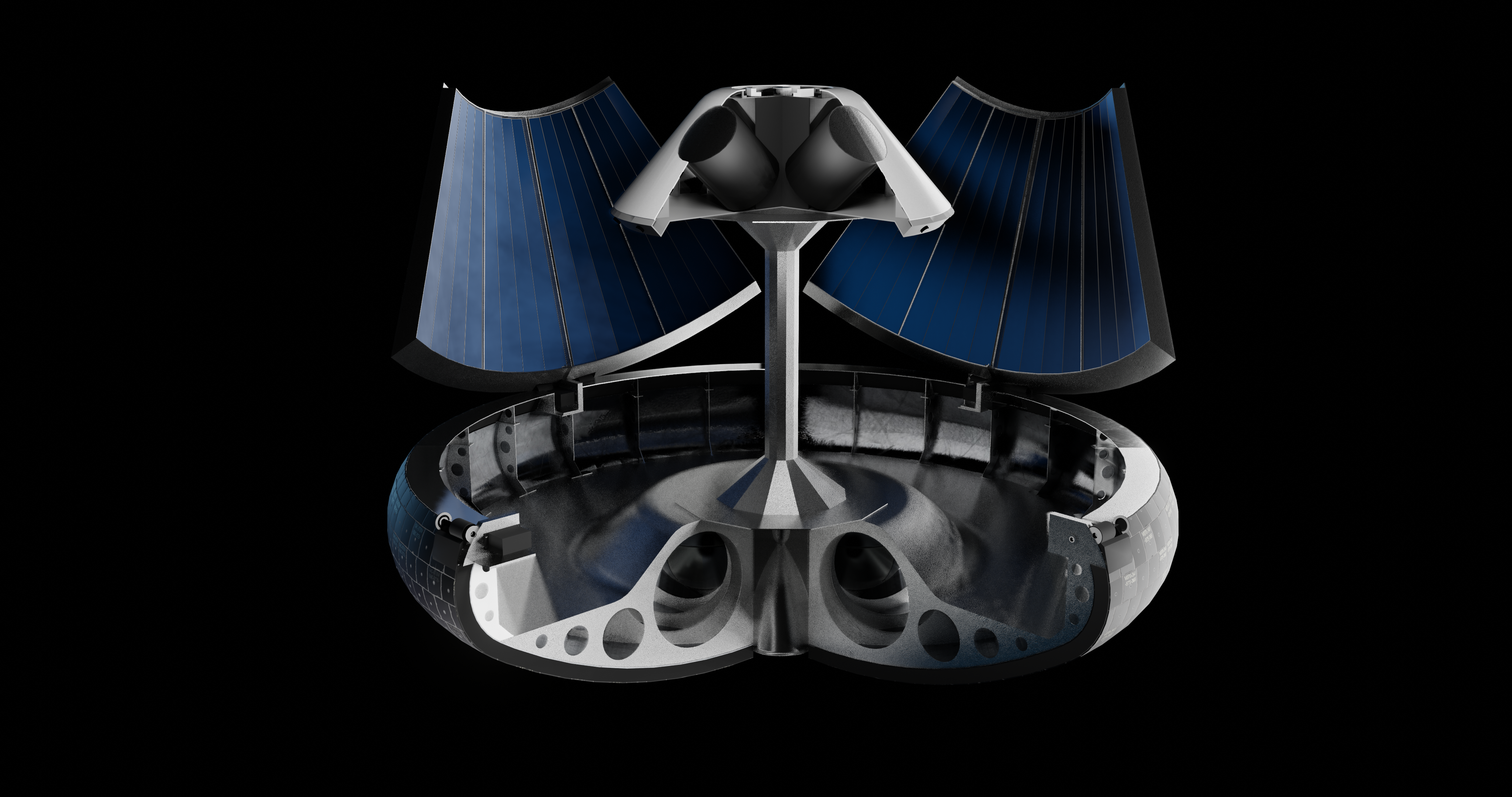

Technical drawings

Dimensions

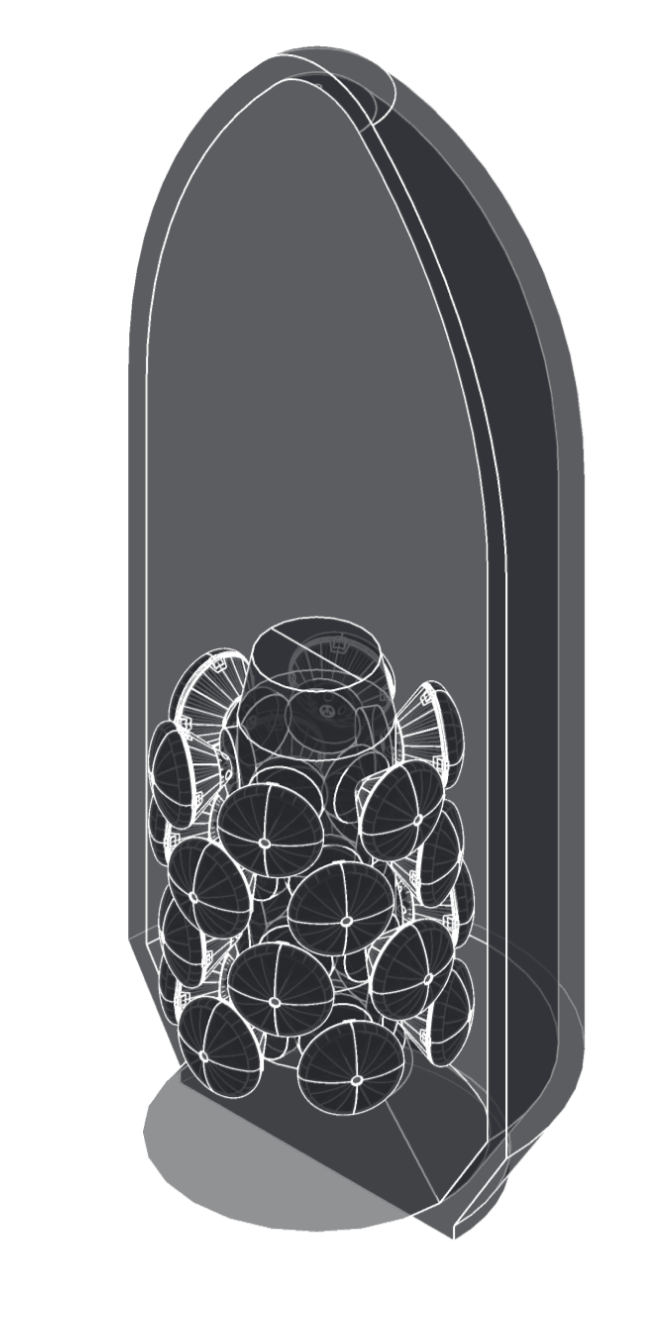

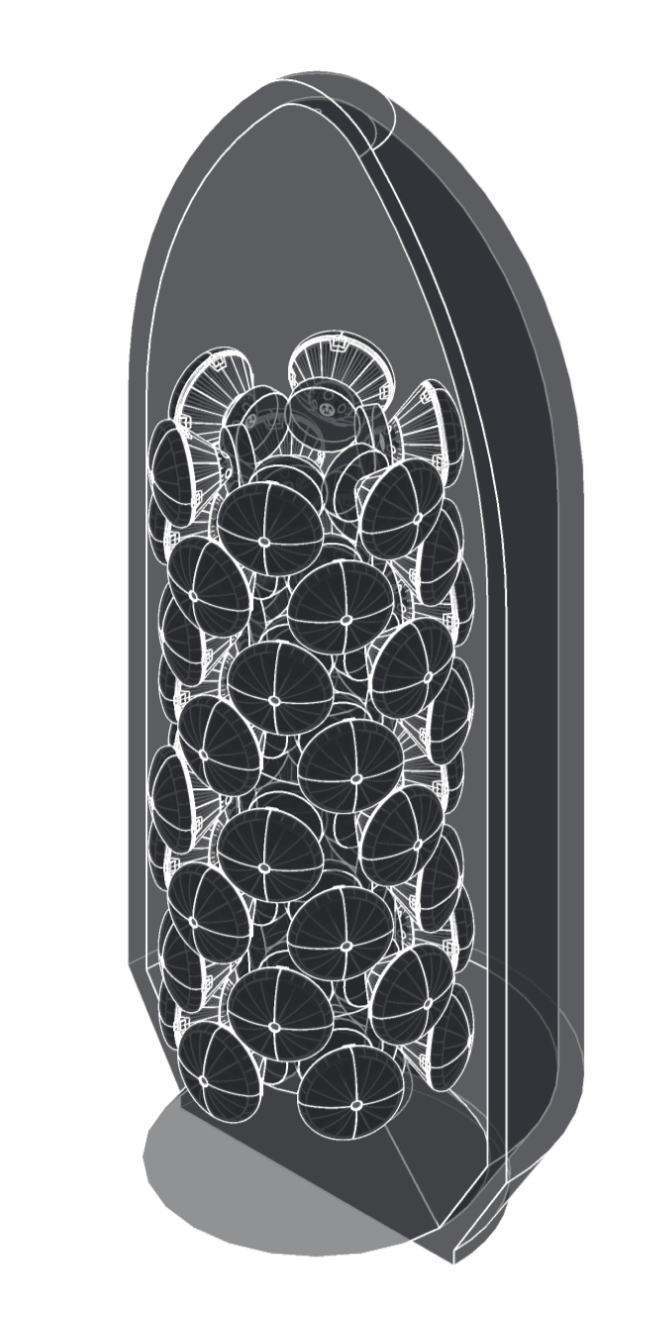

Total mass: 420 kg (100%)

Empty mass: 100 kg (24%)

Payload mass: 320 kg (78%)

Payload volume (max): 800 cm3

Normal ride-share mission

Max vehicles: 24

Payload mass: 7,689 kg

Total mass: 10,080 kg

Expanded ride-share mission

Max vehicles: 48

Payload mass: 15,360 kg

Total mass: 20,160 kg

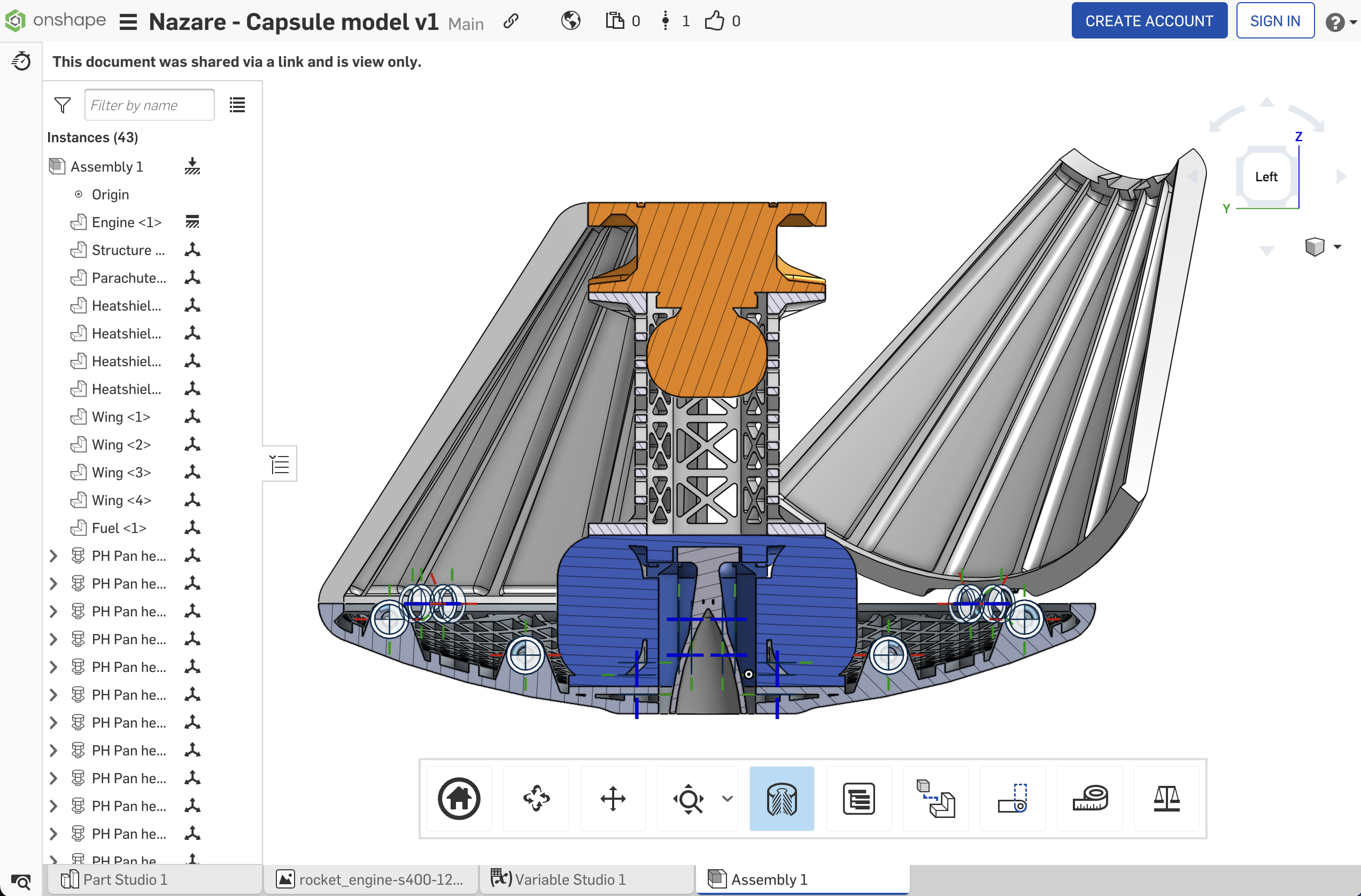

Onshape 3d printable model

You can get the model I did for structural tests at a 1/100 scale and improve on it. Contact me for any questions you might have.

Get the model here.

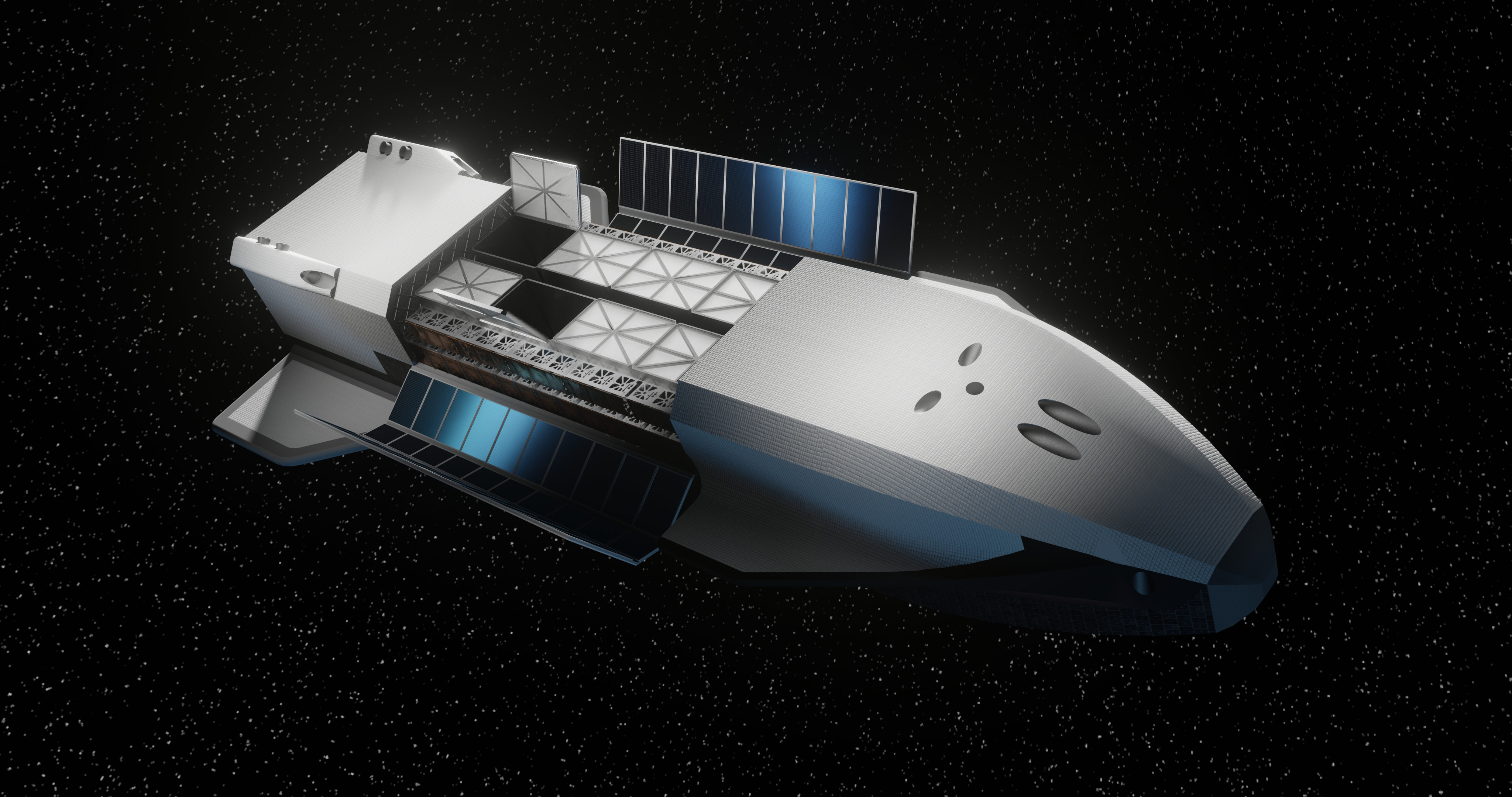

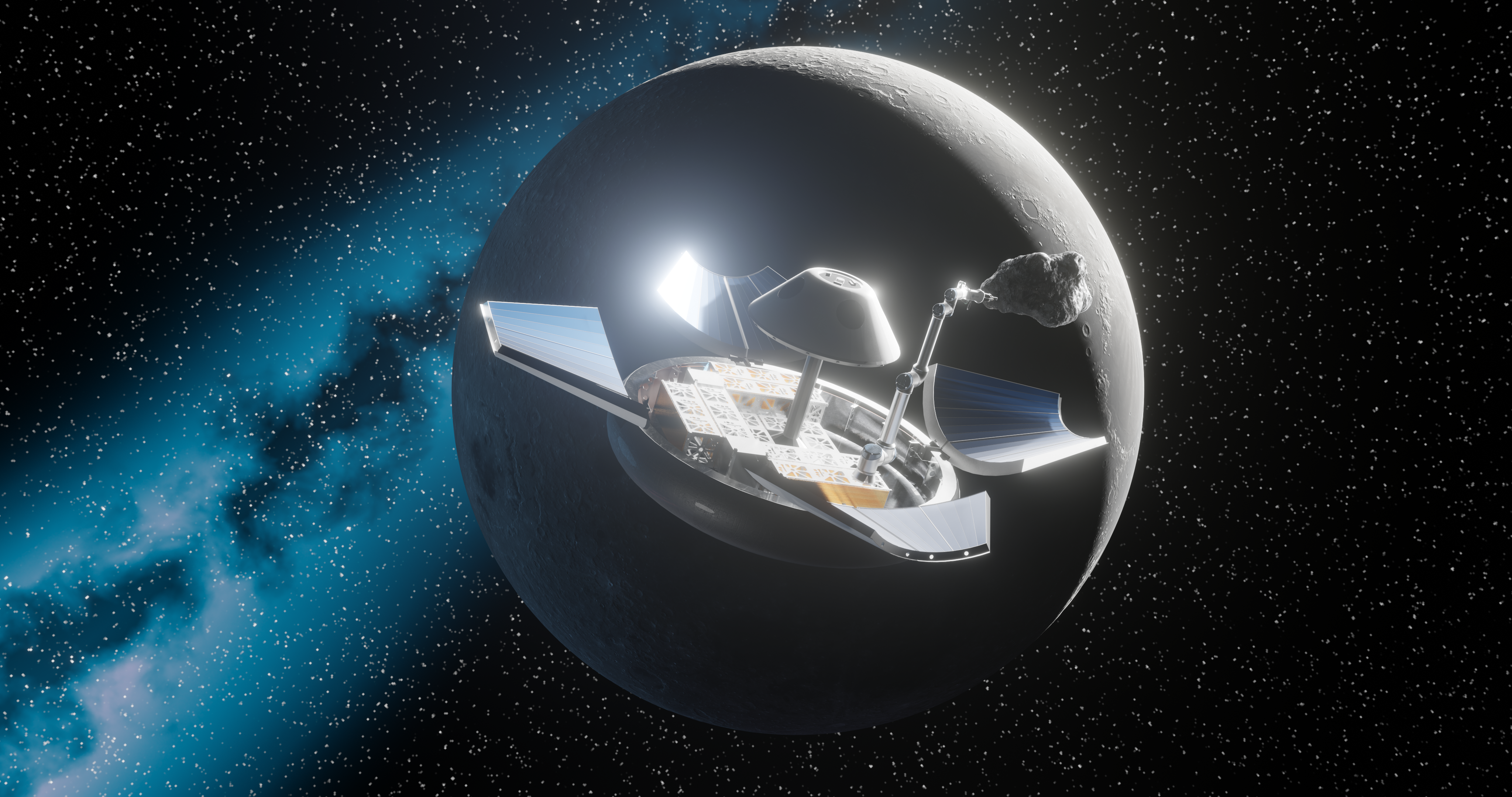

Version 2: Codename Maverick

Designed to increase the ratio of payload mass to total mass and reduce costs of inter-mission logistics, Maverick presents a new challenge: fly large payloads and keep them in orbit for longer periods while reducing the overall mass budget.

Gallery

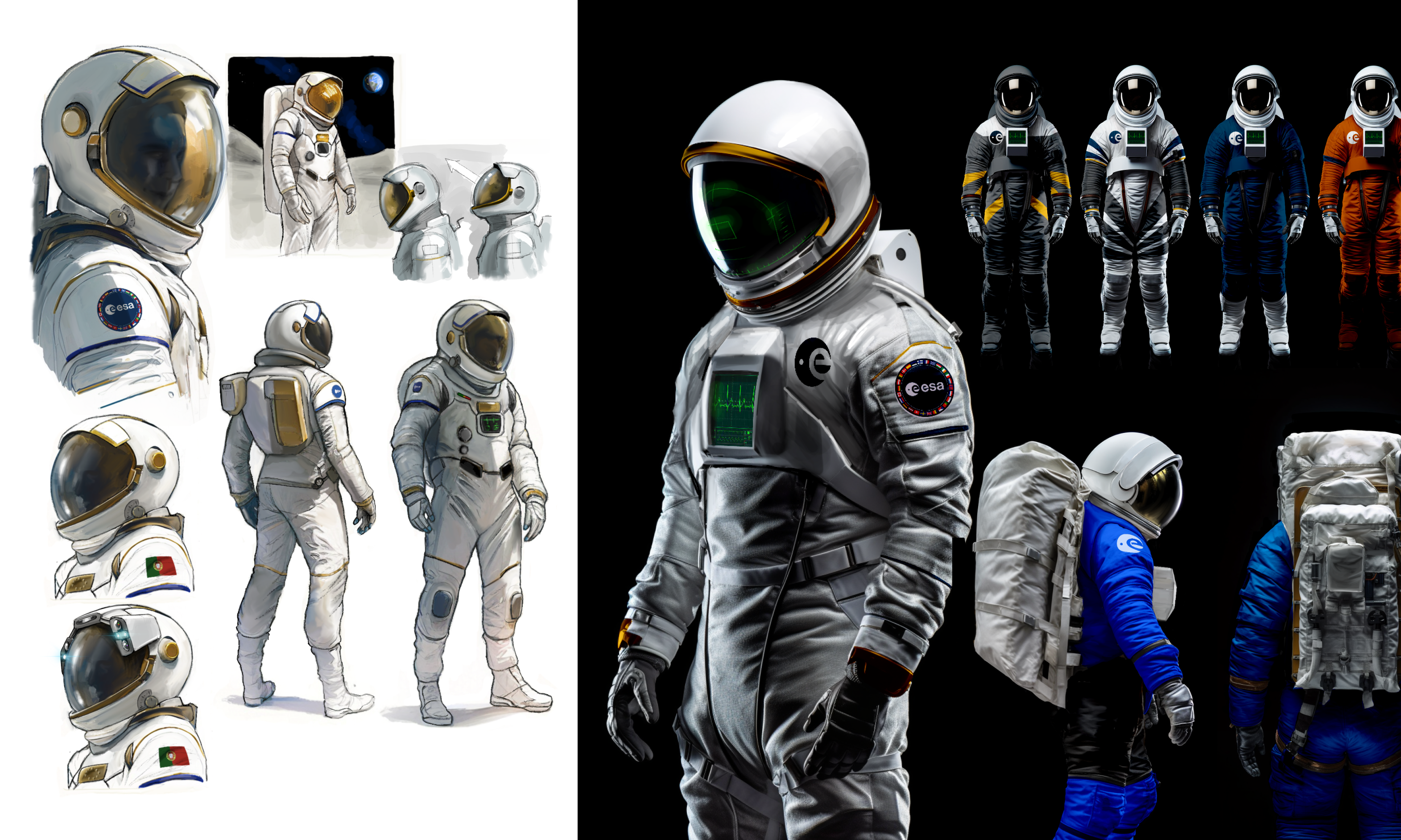

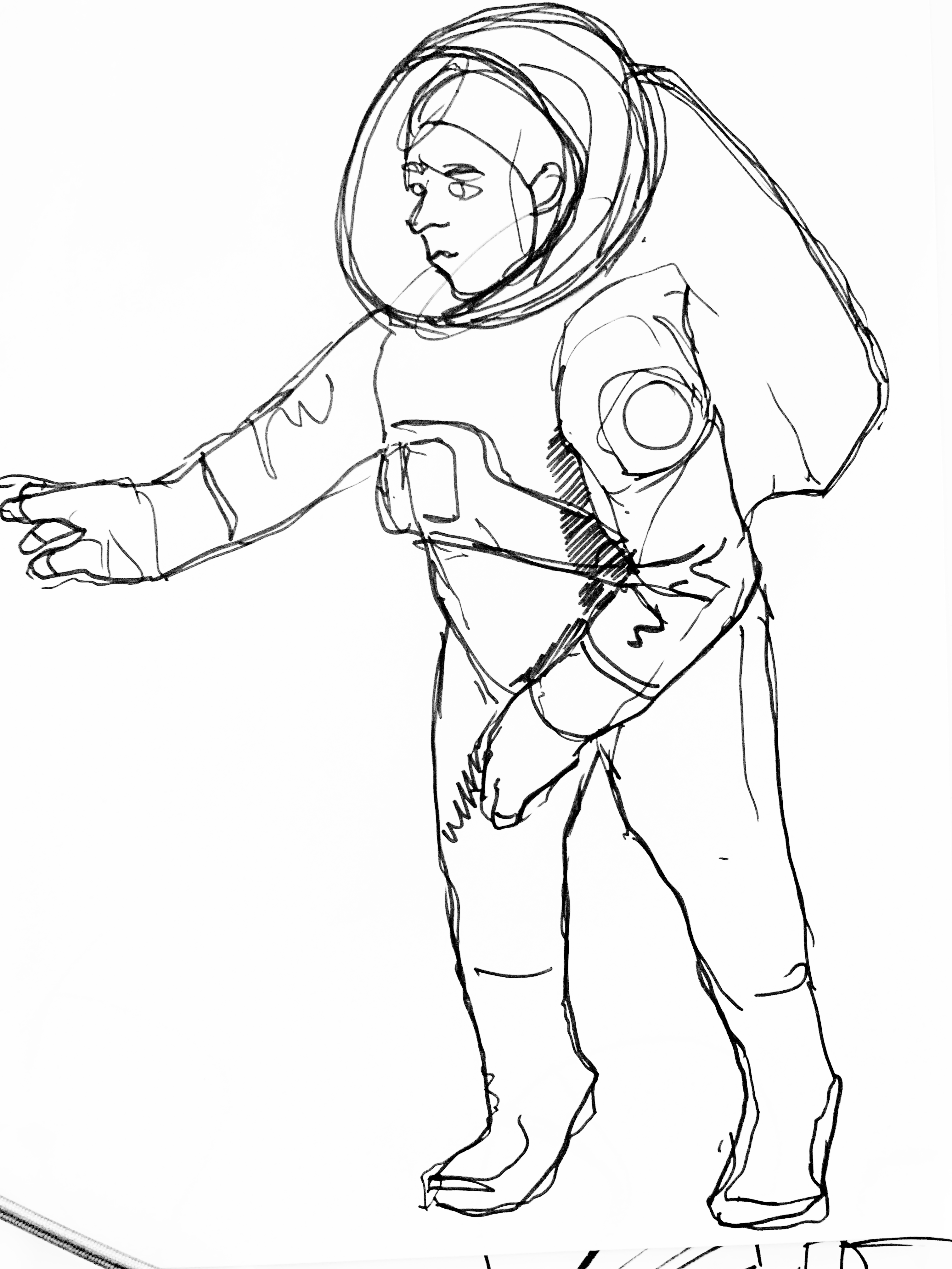

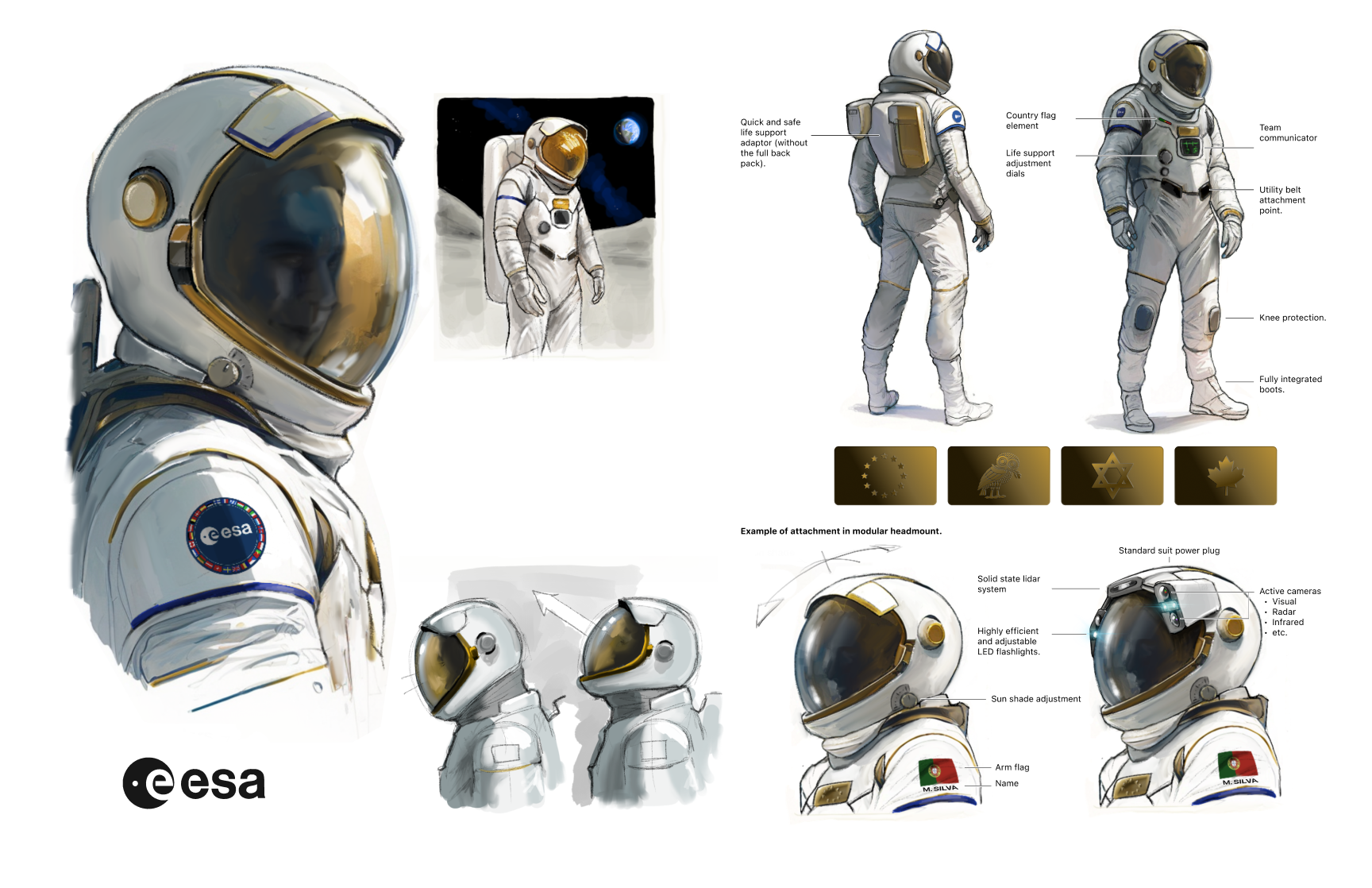

StarKnight Suit

AI-driven Spacesuit design winner of ESA’s Spacesuit 2023 Competition

2023

As Humanity venture’s into a new generation of crewed Moon Missions, the European Space Agency (ESA) is planning to develop a new spacesuit

Starknight is a concept that was selected in the competition “Design a Spacesuit for ESA” open to all populations of the member states.

Overall, this project aims to answer the question:

- can a spacesuit be a vehicle something bigger than the sum of its parts?

- can a spacesuit be a vehicle something bigger than the sum of its parts?

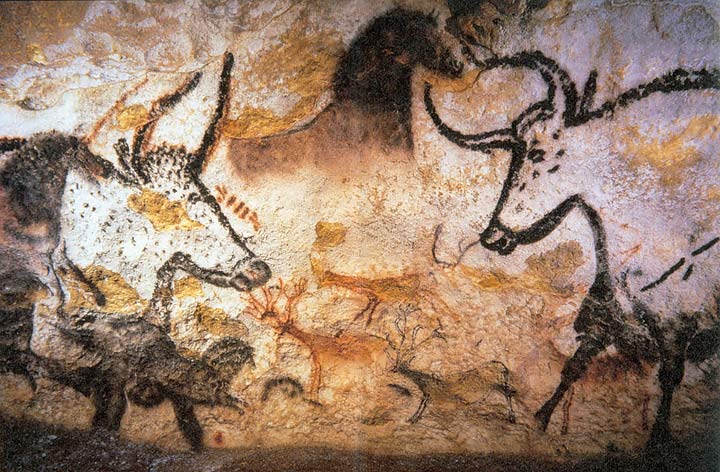

ESA’s civilizational heritage

From the beginning of our existence, humanity has harnessed the art of adornment, intertwining it with practical needs. Our attire serves as a language, subtly revealing our intents and symbolizing our roles.

Space exploration, venturing into unknown realms beyond our terrestrial confines, epitomizes the pinnacle of human accomplishment. It is a feat that cannot be realized without the power of collaborative efforts.

Space exploration, venturing into unknown realms beyond our terrestrial confines, epitomizes the pinnacle of human accomplishment. It is a feat that cannot be realized without the power of collaborative efforts.

The European Space Agency stands as a testament to this bold spirit of collaboration. It unifies 22 nations, each with their own rich tapestry of historical and cultural pride, into a singular, formidable entity.

There is perhaps no finer testament to humanity's collective endeavor over millennia than this joint venture into the stars. So, how might we convey the noble objective of space exploration?

There is perhaps no finer testament to humanity's collective endeavor over millennia than this joint venture into the stars. So, how might we convey the noble objective of space exploration?

How could we communicate this audacious quest as an effort to improve not only our understanding but also the condition of humanity and our planet?

This we do by striving together, by achieving the seemingly impossible through our shared efforts and ambitions.

This we do by striving together, by achieving the seemingly impossible through our shared efforts and ambitions.

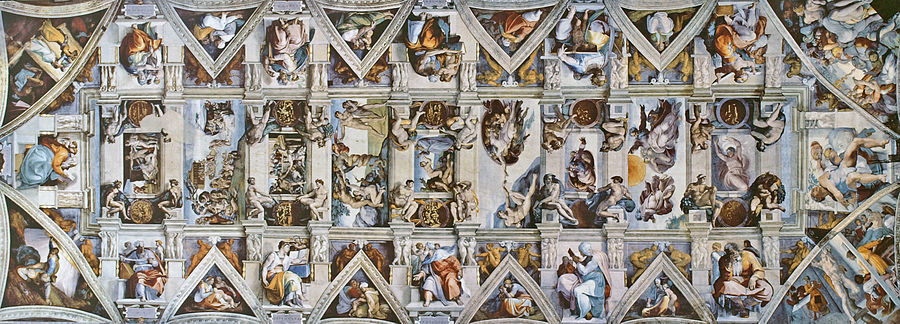

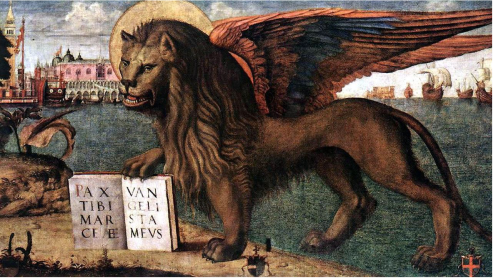

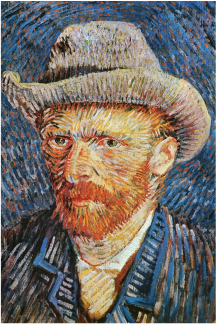

1. Use AI to create something new from our joint history

The approach begins with a simple question: what is it that we bring with us?

To understand this we must first gather images from the past.

These symbols represent the good and the bad, but better yet our continous goal to learn from our past and to build a better future.

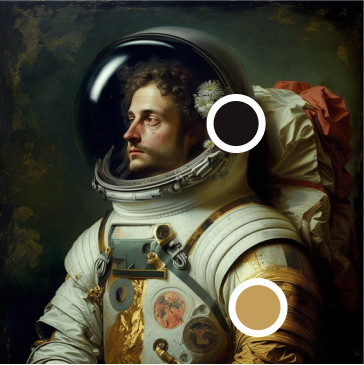

A few examples of the images used as references.

2. Making sense out of artificial generations

Although AI is a great tool, it is indeed just that a tool. In the case of this process, the generated images were tuned to incorportate many of the symbols and thus produced inspirational images, not a final product.

Out of these images, though it became possible to understand the materials, colors, and decorative elements that could then be used for our design concept.

Regardless of the materials some of the design problems became clear:

- celebrating cultures differently

Designed for new envirnoments

An astronaut suit is one of the most complex pieces of technology to design.

In the end it is a wearable spacecraft capable of supporting human life during several hours of labour in extreme environments.

To begin, we need to consider the spacesuit’s environment. For the past decades, astronauts have not ventured beyond Low Earth Orbit (LEO), but in the comming years, this will change.

The first new environment will be the Moon.

This type of environment is much tougher to work on when compared to LEO.

Especially because of:

- Gravity. Even at 1/6th of Earth’s, the very heavy spacesuits make it very hard for astronauts to move around.

- Radiation. The Moon lies beyond the Van Allen belts and most of the Earht’s magentosphere. This makes it much more subject to solar and galactic radiation.

- Temperatures. The moon has a 27 day long translation AND rotation period around the Earth, this means that half that time, the ground is either exposed to contious sunlight or in permanent shade.

The Moon also doesn’t have any atmosphere, which would distribute the temperature evenly. This way sunlit areas might be 100K to 200K hoter than the shadows.

- Regolith. It’s everywhere and sharp as glass. The moon’s “dirt” is actually much different from the Earth’s soil, especially since it is not eroded by wind and water, making each grain a microscopic glass shard that gradually can pierce any fabric, metal, plastic or human skin...

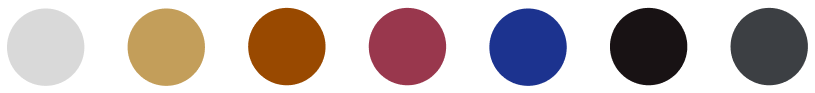

Design sketching

One of the clear tradeoffs for designing a suit appears imediatly: the helmet design.

A helmet must be able to provide visibility AND to allow for shading elements.

One of the imendiate problem lies in head movement. Although in space movies, helmets are designed with articulated necks, this is usually avoided in spacesuit design.

Why?

Well, there are several benefits for fixed helmets, such as:

- less likelyhood of visor fog.

- ability to use wearables inside the helmet as there is a larger volume

- ability to use drinking straws, food supply or the use of Valsalva device.

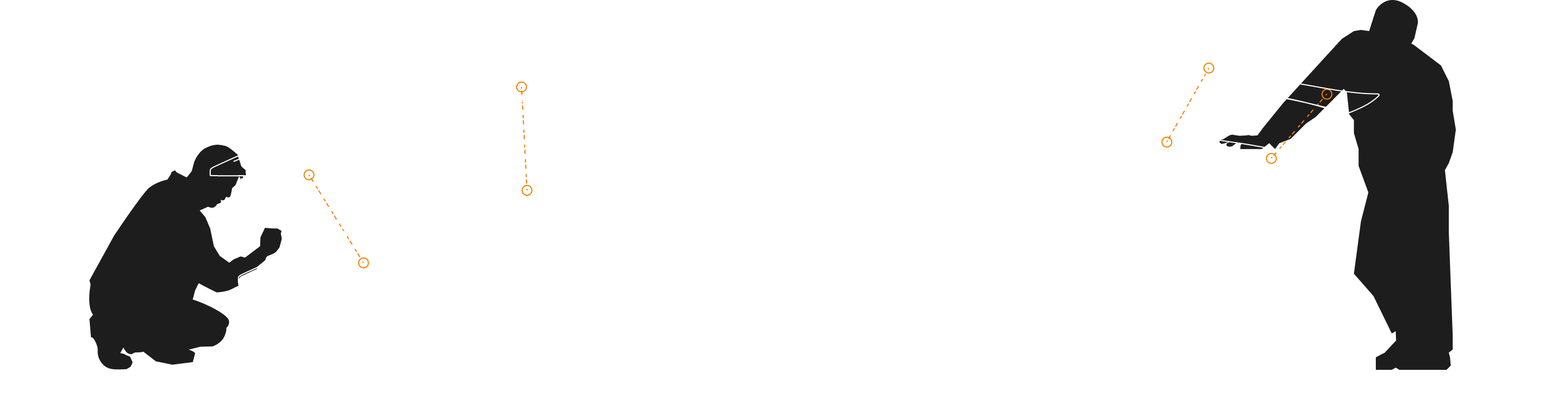

Below is the final concept drawing of the suit given all these constraints.

Communication is key for mission success. This means:

- quickly explaining roles

- indicating vital sings to team members

- expressing the astronaut’s personality, cultural heritage, etc.

This last point I believe to be as important as all others, otherwise why send people to space at all?

Details

One of the hardest components to design are the gloves.

Astronauts need to work continuously with tools and manipulating their environment for multiple hours.

This means that gloves are subject to extensive wear and tear, and a major failure point.

The fact that spacesuits are preassurize and climate controlled means taht they need to be especially thick. This makes it hard for astronauts to gesticulate and move their fingers. The continuous pressure also regularly hurst astronauts finger nails, fingers and nails.

Here’s a simple sketch of the glove systems with clearly separated friction elements and harder top covers with radiative capabilities.

This means that:

- these gloves can avoid wear and tear in the grip layer

- they can also provide protection againts impacts in the upper hand area.

HUD and AR capabilities

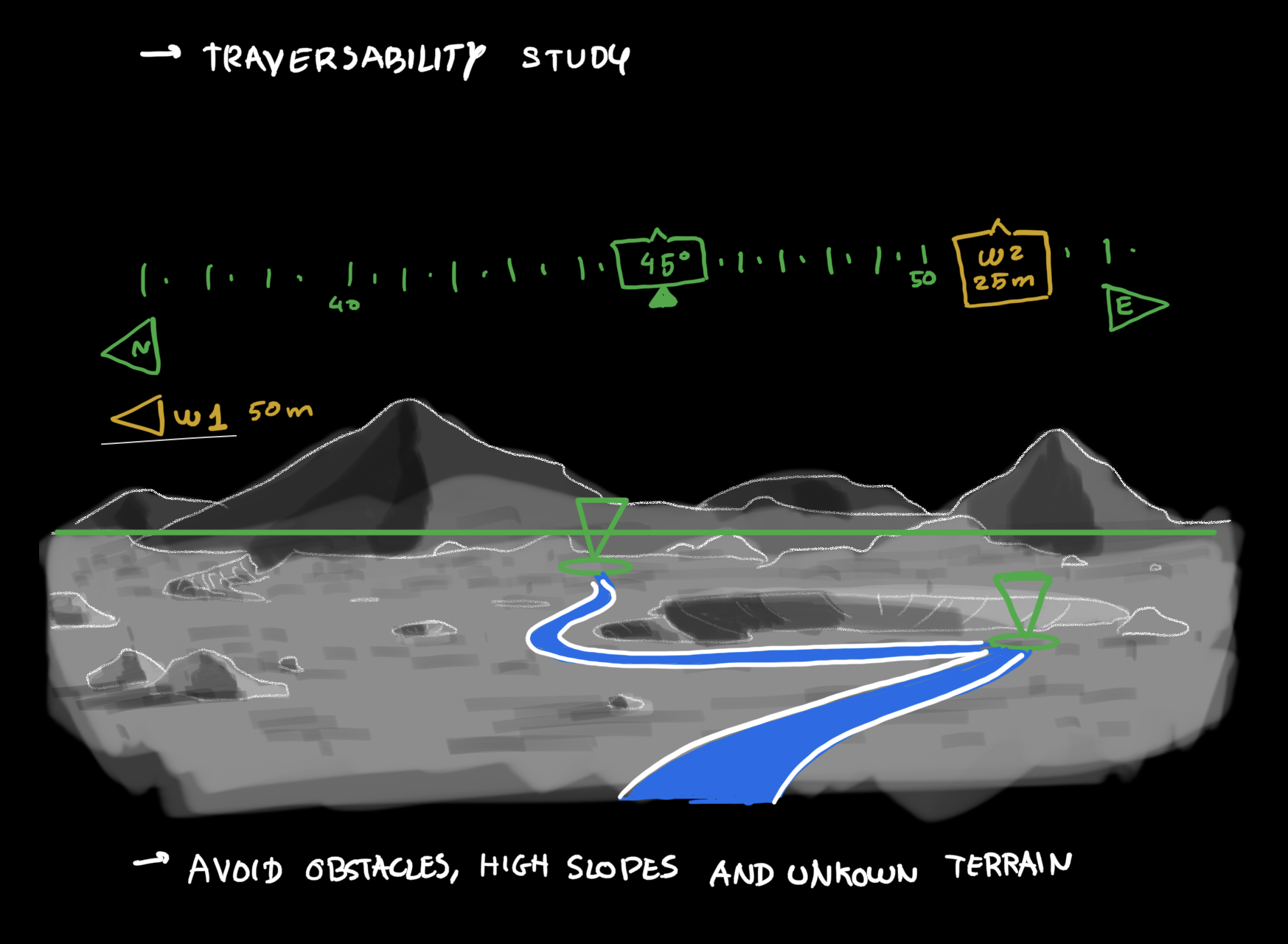

Astronauts have a hard time moving through the strange Moon terrain. This is due to mainly two factors:

1. Regolith reflects sunlight in a different way than most environments on Earth. This makes it hard to understand shapes on the Moon. “Is that a crater? Or perhaps a mountain?” This was especially complained about by a few of the Apollo astronauts during EVA’s as they took much longer to navigate the surface.

2. No lunar GPS. At least for now, there will be no lunar GPS. This means that astronauts will need help to gavigate locally as well as keep track of longer distance markers in the case of farther expeditions.

Beyond navigation there are many benefits for HUD systems:

- communicating with other astronauts and mission control

- object recognition and highlighting (geology or hazard avoidance)

- keeping track of life support metrics (as well as time, temperature, radiation, etc).

“3dFication”

In order to get a sense of the final design, a process was used that gets data from a simple 3d model, and use it to generate more advanced AI generated images. Although these images still require a lot of post-processing.

Colors

Why are astronaut spacesuits usually white? Again, it’s not by pure chance or lack of imagination.

The spacesuits need thermal regulation due mainly to two factors:

1. ECLSS and other heatproducing systems - The Environmental Control and Life Support System requires to radiate heat from all the interior machinery. However, on the Moon or LEO there’s no atmosphere hence heat needs to be conducted in the form of radiation.

2. Reflecting sunlight. Due to similar reasons as the previous factor, heat from the sun needs to be reflected and white fabric does this well.

However, color is important to:

- communicate roles and mission activities

- visualize other astronauts in the middle of the

- astronaut’s personal and cultural personalization.

This way, this section is a sugestion for engineering development of better fabric that can use color as well as preform in space’s hostile environments.

Heavy duty tracking

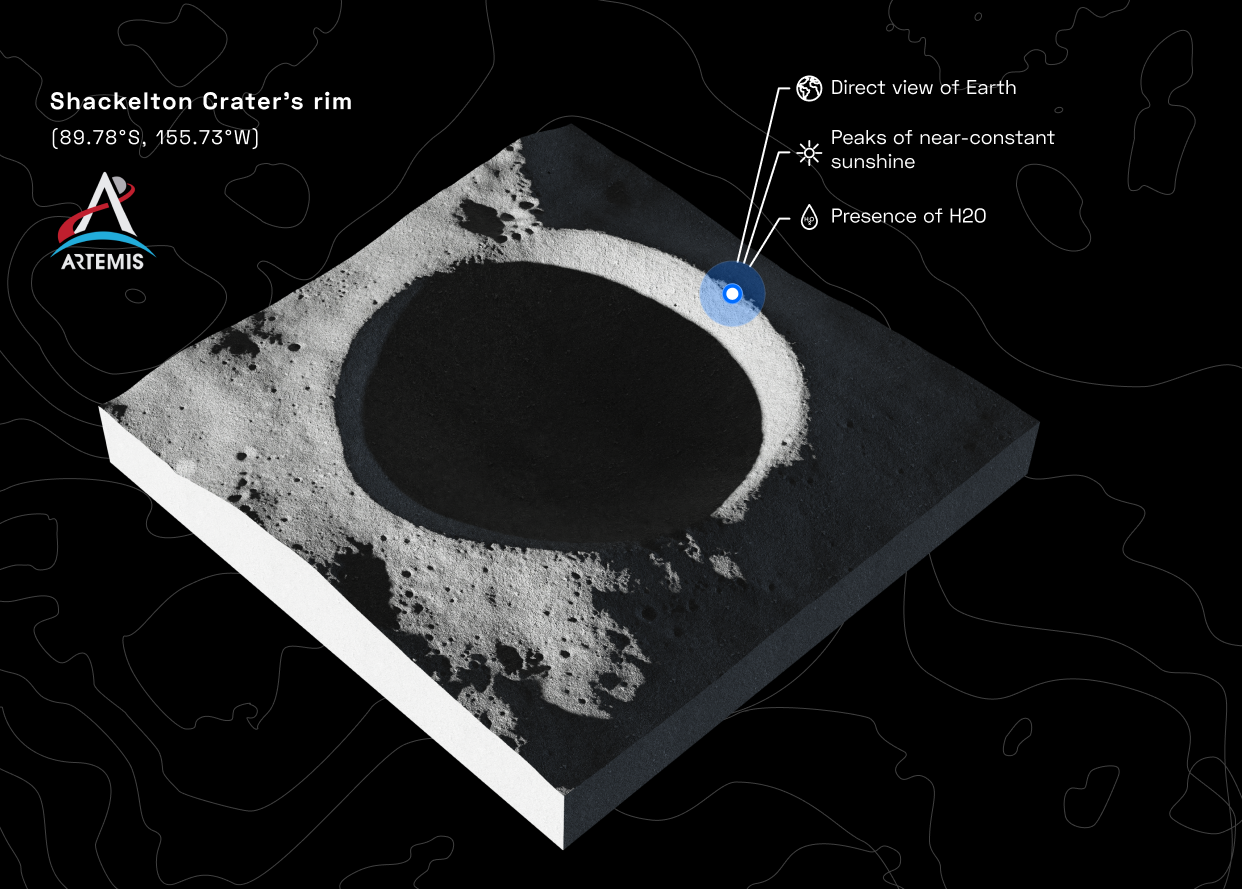

Artemis missions are aimed at exploring the Moon’s southern regions. This is an area that is extremely different from where the Apollo missions took place, it is filled with harsh terrain, steep climbs, and deep craters.

This way, astronauts need to be ready to gear up and hike.

The final design

Although only explored in an inital iteration, the Starknight spacesuit is an unique piece of equipment, ready to take ESA’s Human spaceflight into the next era of exploration.

Here’s a list of components that are yet to be developed thoroughly:

- Adapting the suit to people of different sexes and body types

- Design for assembly

- Design for better dress-in and out

- Boot design

- Backpack design

Here’s a list of components that are yet to be developed thoroughly:

- Adapting the suit to people of different sexes and body types

- Design for assembly

- Design for better dress-in and out

- Boot design

- Backpack design

Media

Prize

This suit was awarded as one of the 5 winners of the ESA Spacesuit design 2023 competition. You can see more details here.

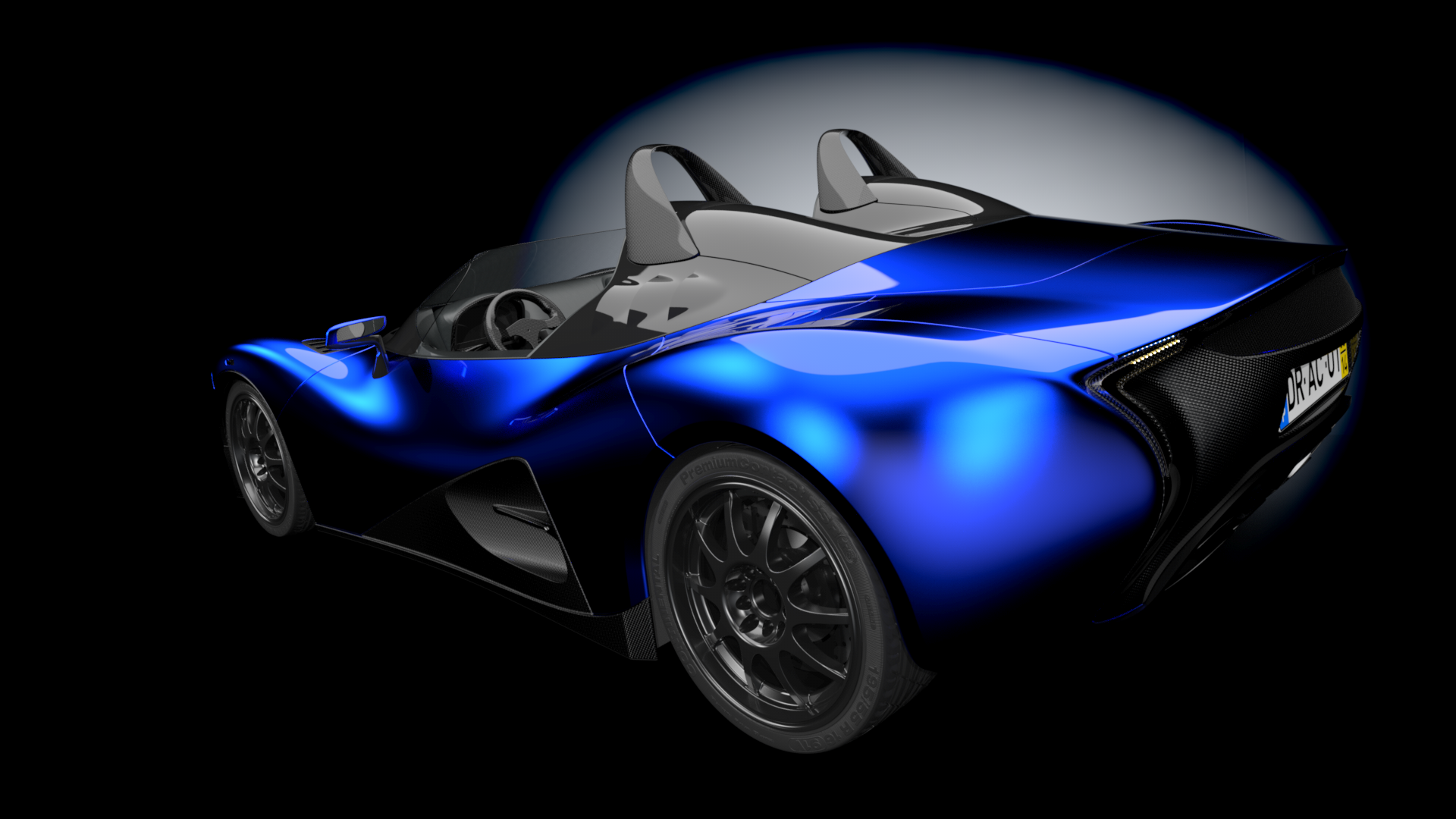

Draco

Sports car design for Adamastor

2012-2015

Follow Adamastor for the latest news at

https://adamastor.com.pt/

Designed in the shape of the natural driving experience, Draco is a sports car that personifies the daredevil spirit of the 1960s races and mixes it with craftsmanship and details.

The shape was the culmination of a 1-year long design process in collaboration with the innovative Adamastor engineering team.

The form of Draco's design attempts to create an automobile from a single surface; this way, it is sculpted out into a natural aerodynamic body of glass and carbon fiber.

The form of Draco's design attempts to create an automobile from a single surface; this way, it is sculpted out into a natural aerodynamic body of glass and carbon fiber.

Draco is the rebirth of the driving experience as art. With a growing mass market of vehicles that take their drivers from point A to B, the adventure and passion for racing become the racetrack for Draco.

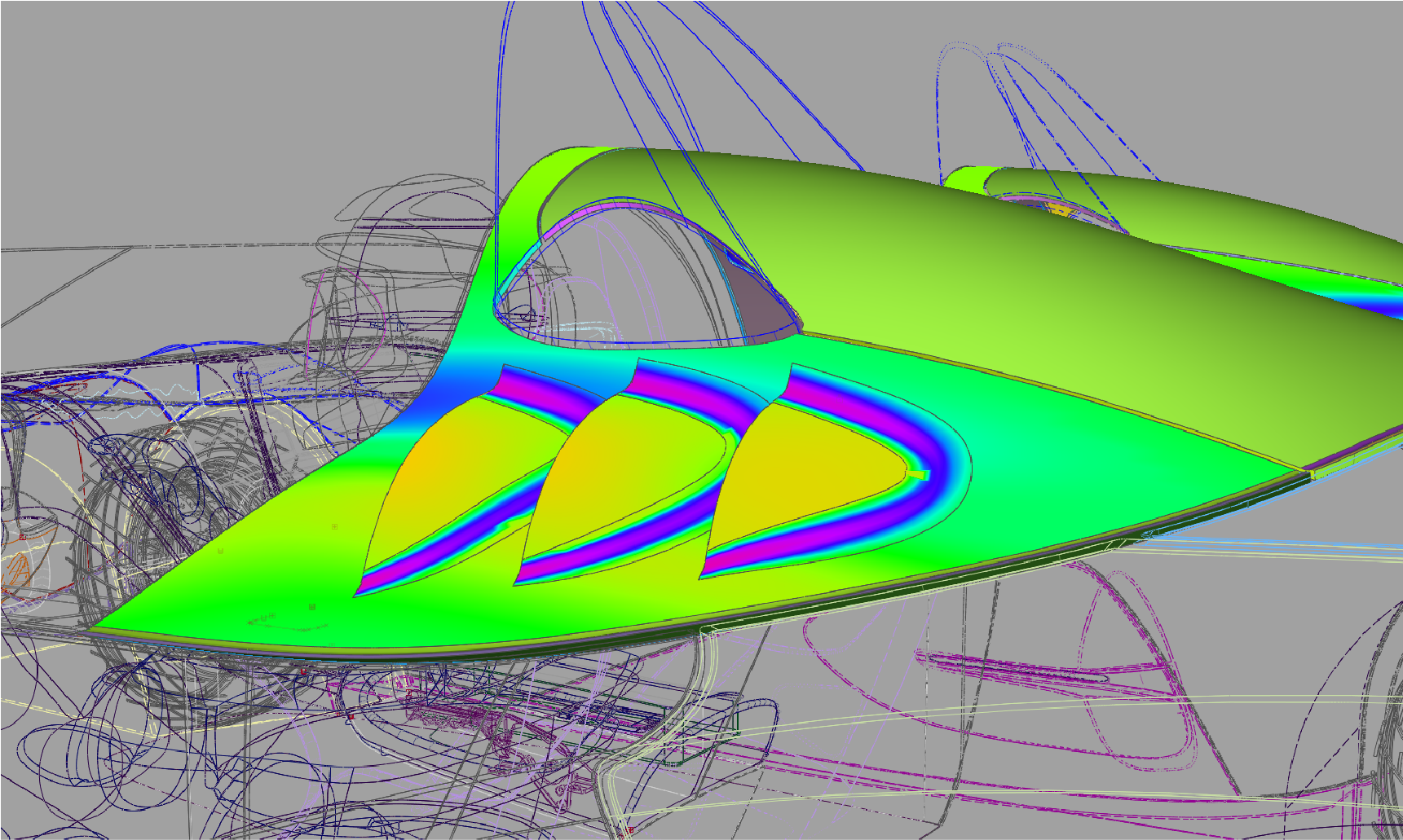

Curvature analysis of the front-light mount...

Curvature analysis of the front-light mount... ... and of the anterior air intake.

... and of the anterior air intake.

After this first proposition, which got track tested, the company Adamastor developed the product further and eventually achieved new iterations of the design.

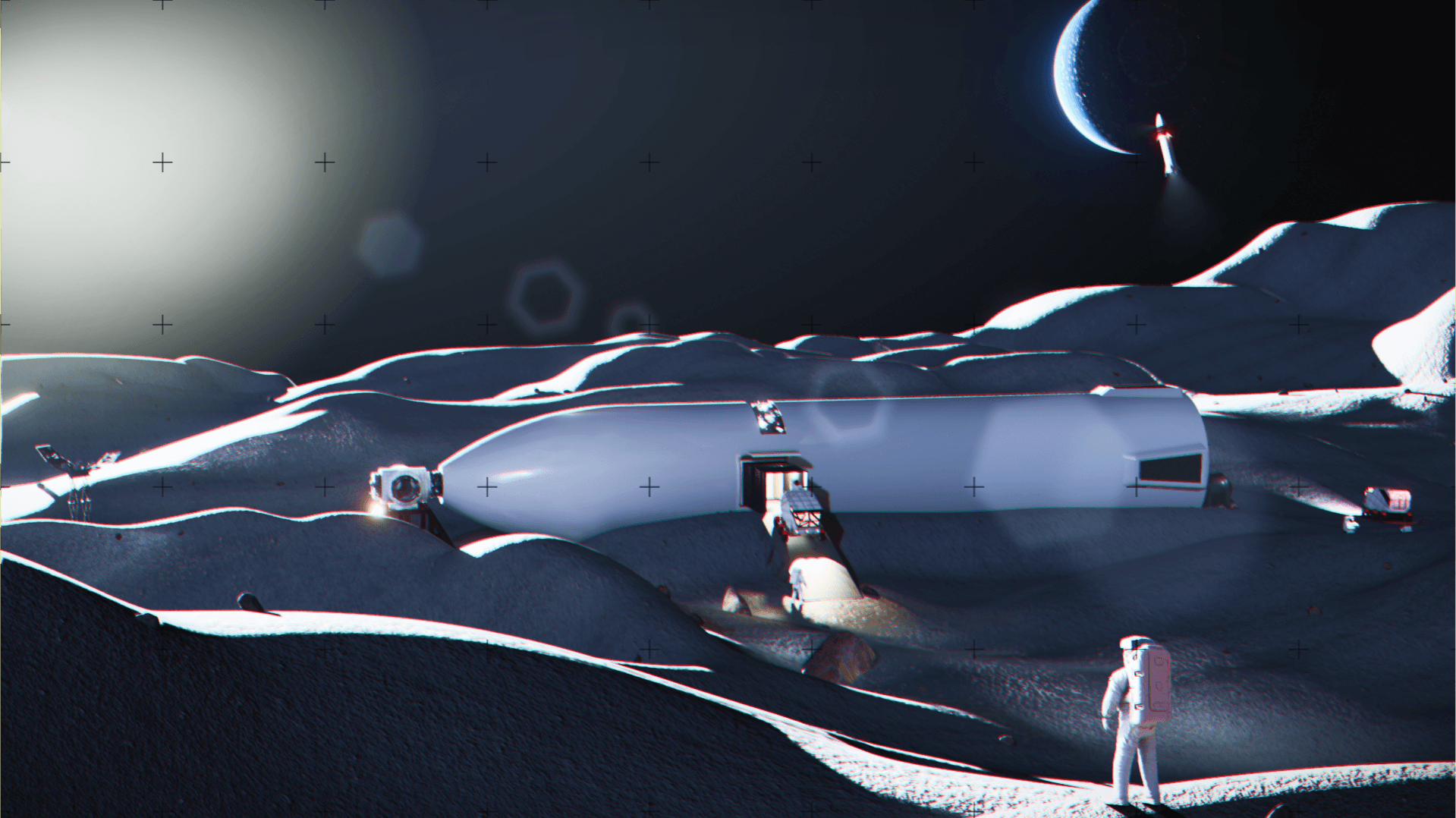

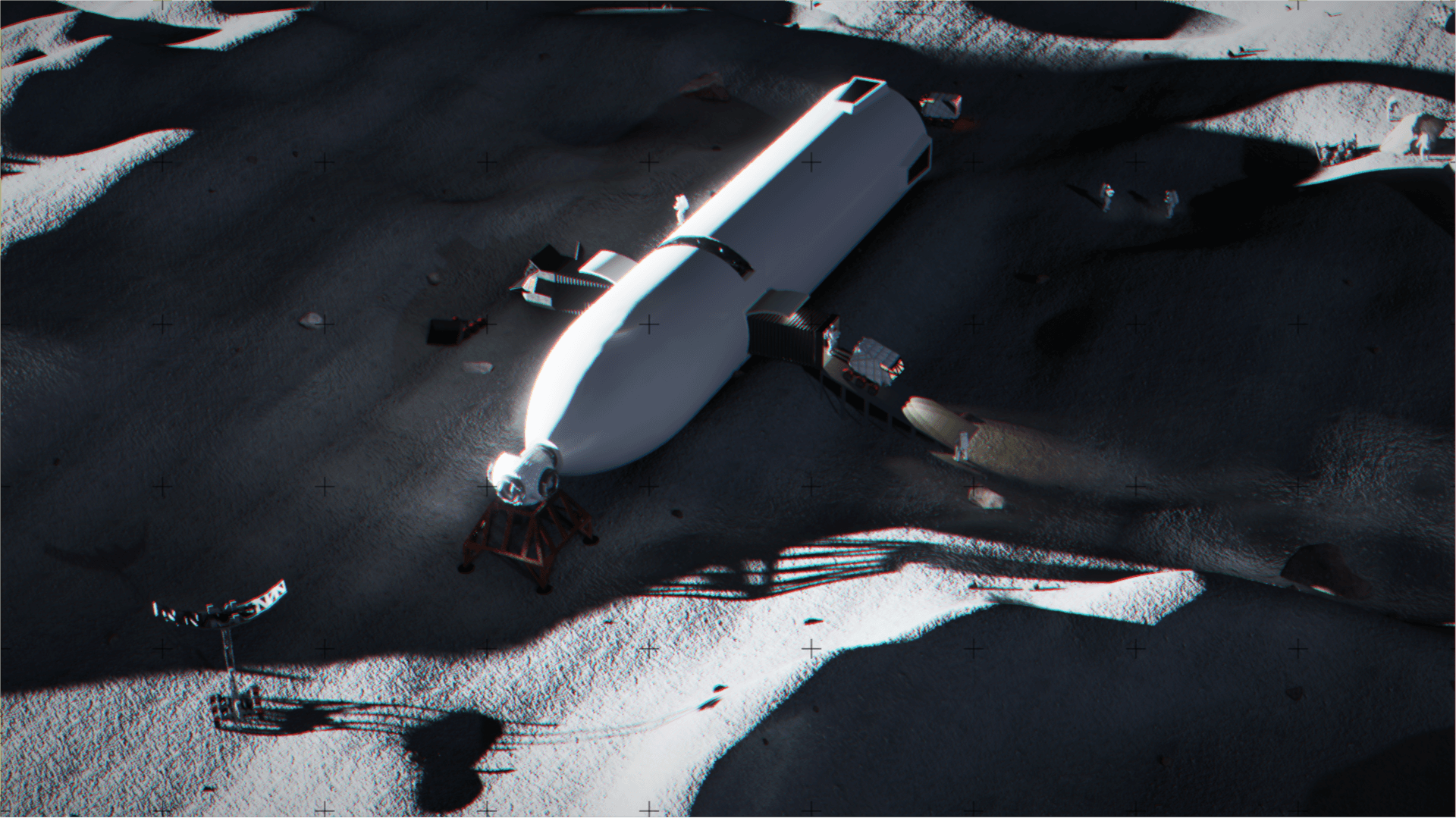

Rosas Moon Base

A lunar base designed by repurposing SpaceX Starships

2021

The next step forward in space exploration is returning humans to the Moon and establishing a permanent human presence.

Sending humans to the Moon encompasses challenging environmental factors to human performance and health.

Current state-of-the-art technologies, like the Artemis program and the SpaceX Starship Human Landing System (HLS), is the inspiration of the Rosas Mission, to ensure feasibility and optimize human performance.

"The Moon is the first milestone on the road to the stars" - Arthur C. Clarke.

The pains of building a lunar base

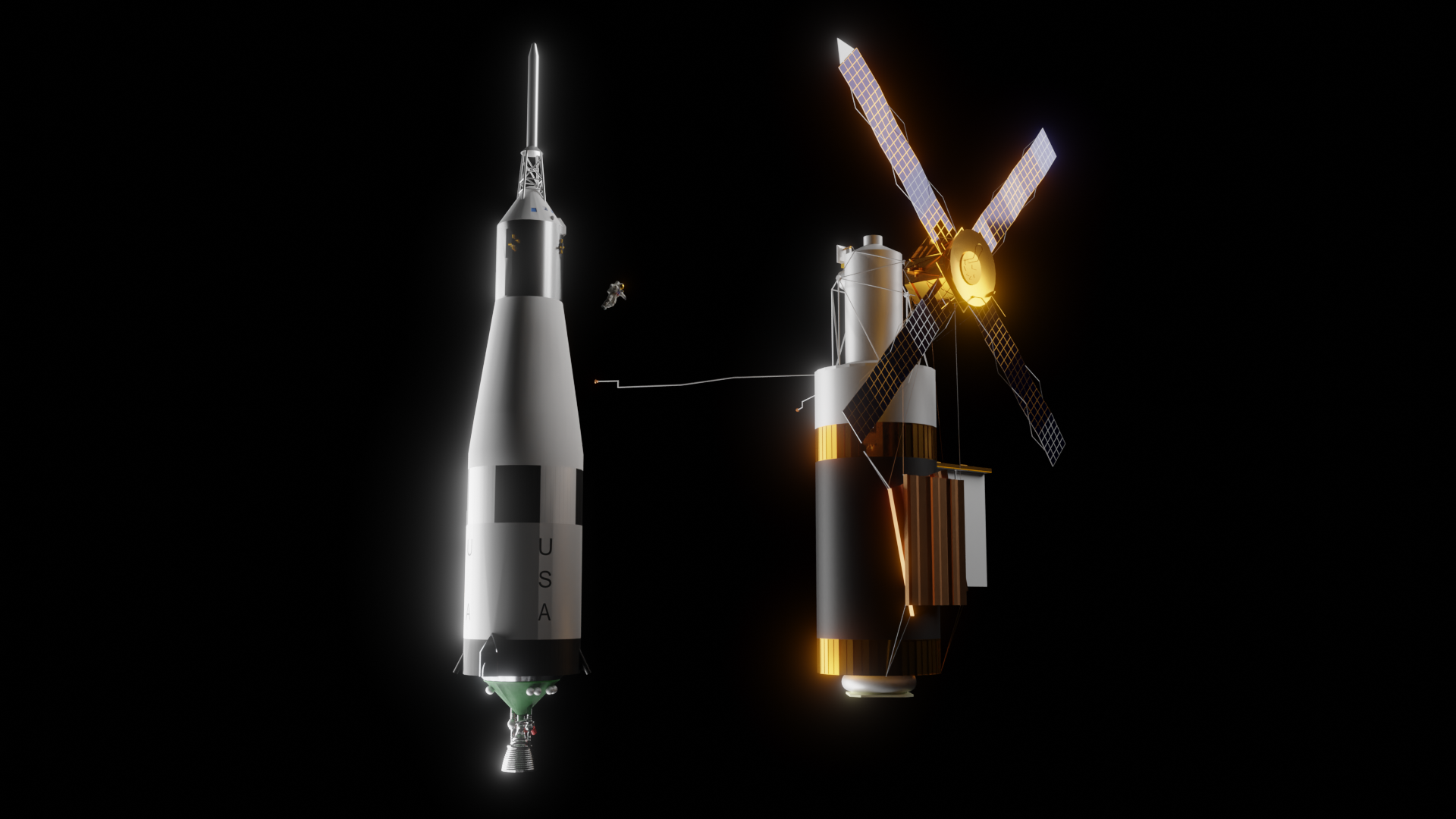

1973: The Saturn V and the explored Saturn Workshop, best known as Skylab:

![The Saturn V upper stage on the left, and Skylab on the right; with astronaut for scale. Modeled in Sketchup, rendered in Blender.]()

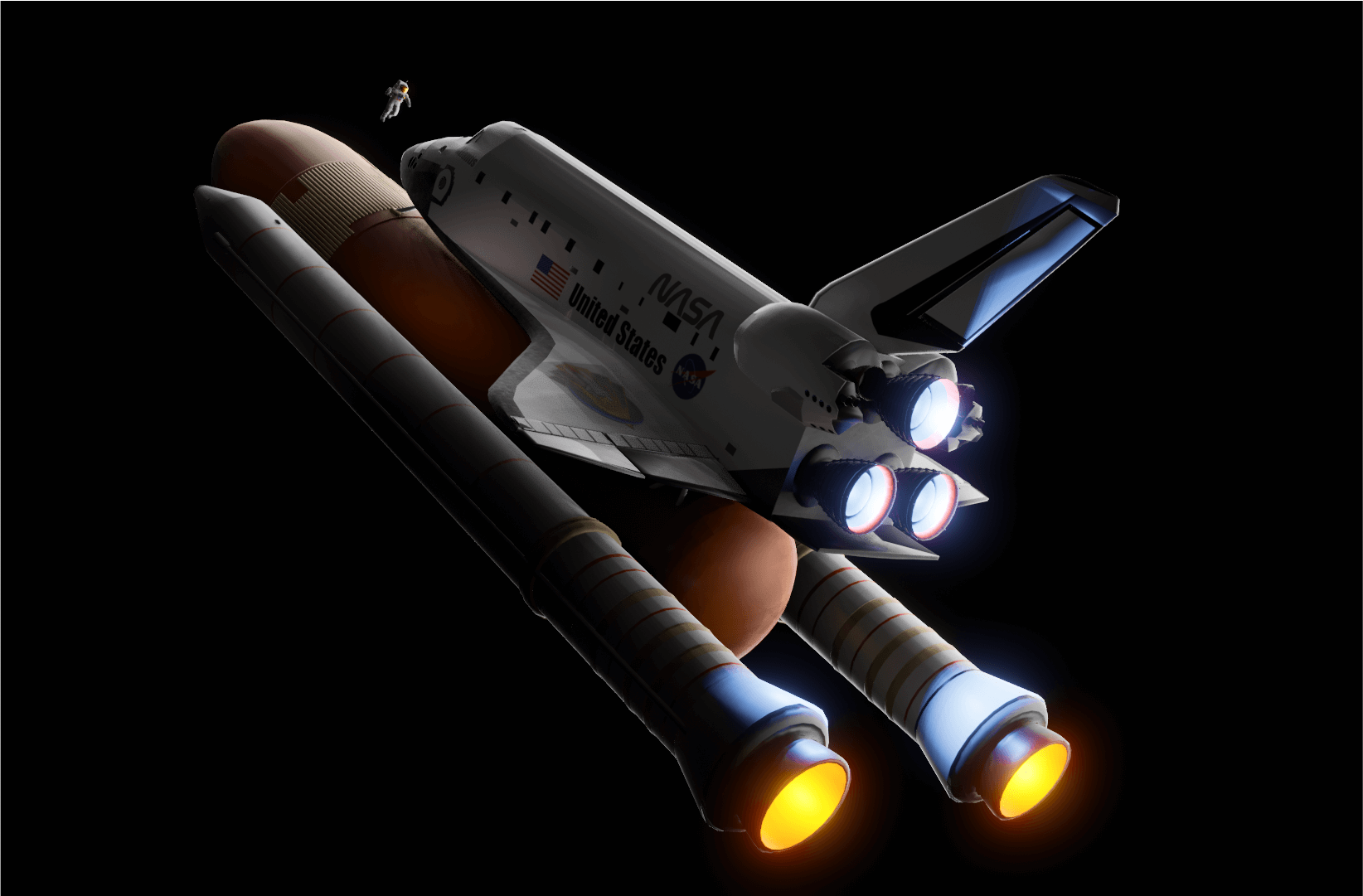

1992: STS-Lab Space station Concept (Ware and Culbertson, 1992):

![The Space Shuttle; modeled in Sketchup, rendered in Blender.]()

![The Enterprise Shuttle Space Station; NASA]()

1992: STS-Lab Space station Concept (Ware and Culbertson, 1992):

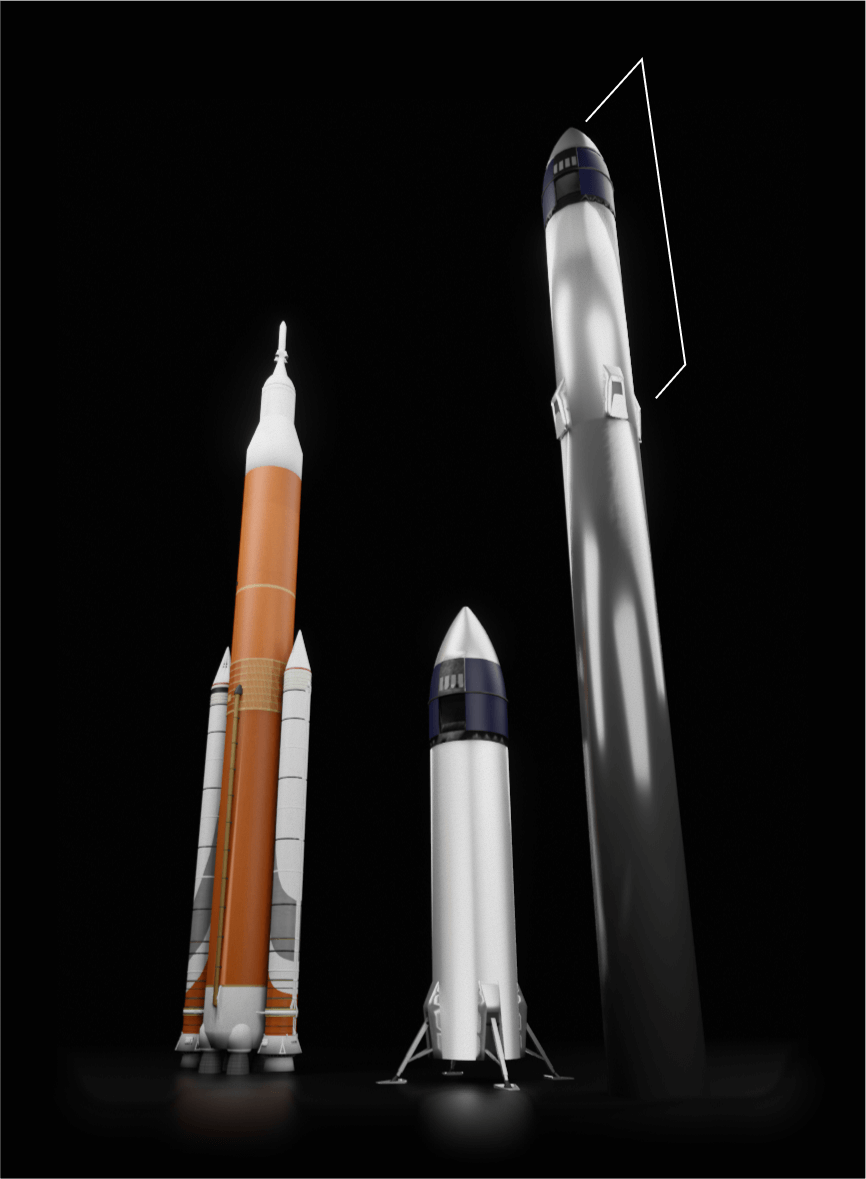

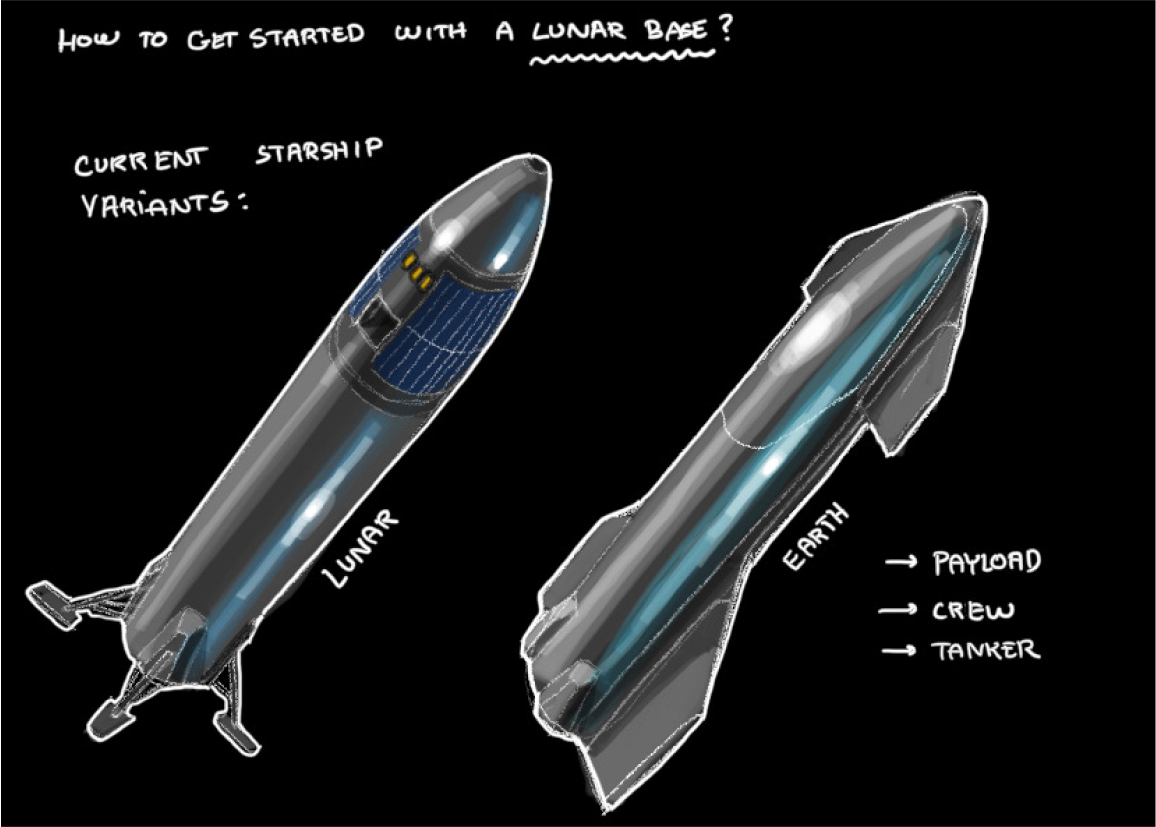

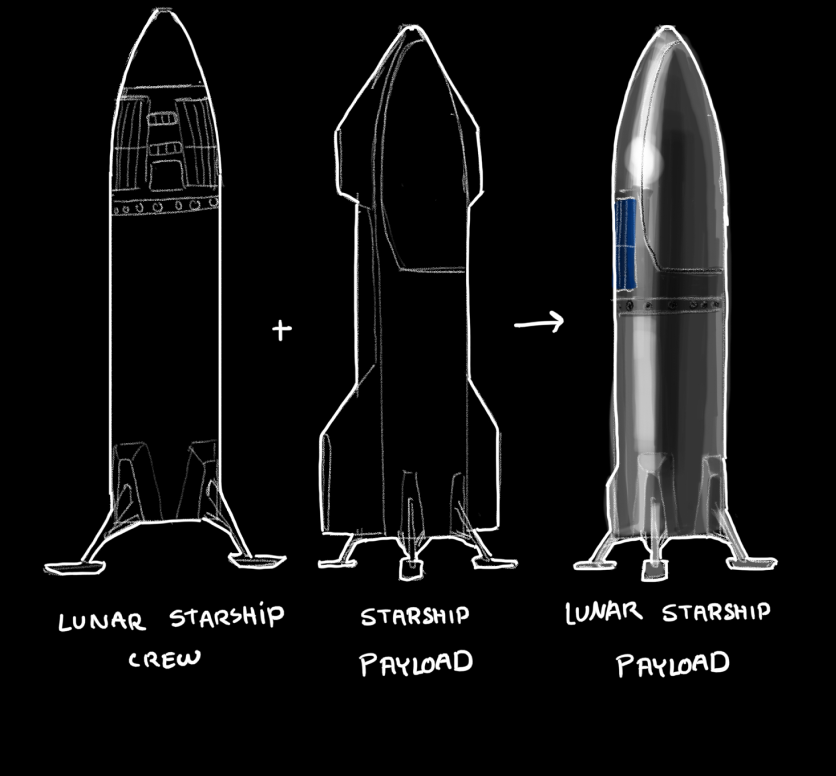

Today: SpaceX Lunar Starship

The upcoming, largest, piece of infrastructure in history that can land on the Moon.

![From left to right: Space Launch System Block II; Lunar Starship (landed); Lunar starship mounted on top of Superheavy]()

The upcoming, largest, piece of infrastructure in history that can land on the Moon.

Concept generation for the base design

Before proceding with the engineering design, a series of concept proposals were explored.

With this rapid sketching of the baseline mission it was possible to arrive to a stronger concept in a faster way.

Horizontal hypothesis base concept

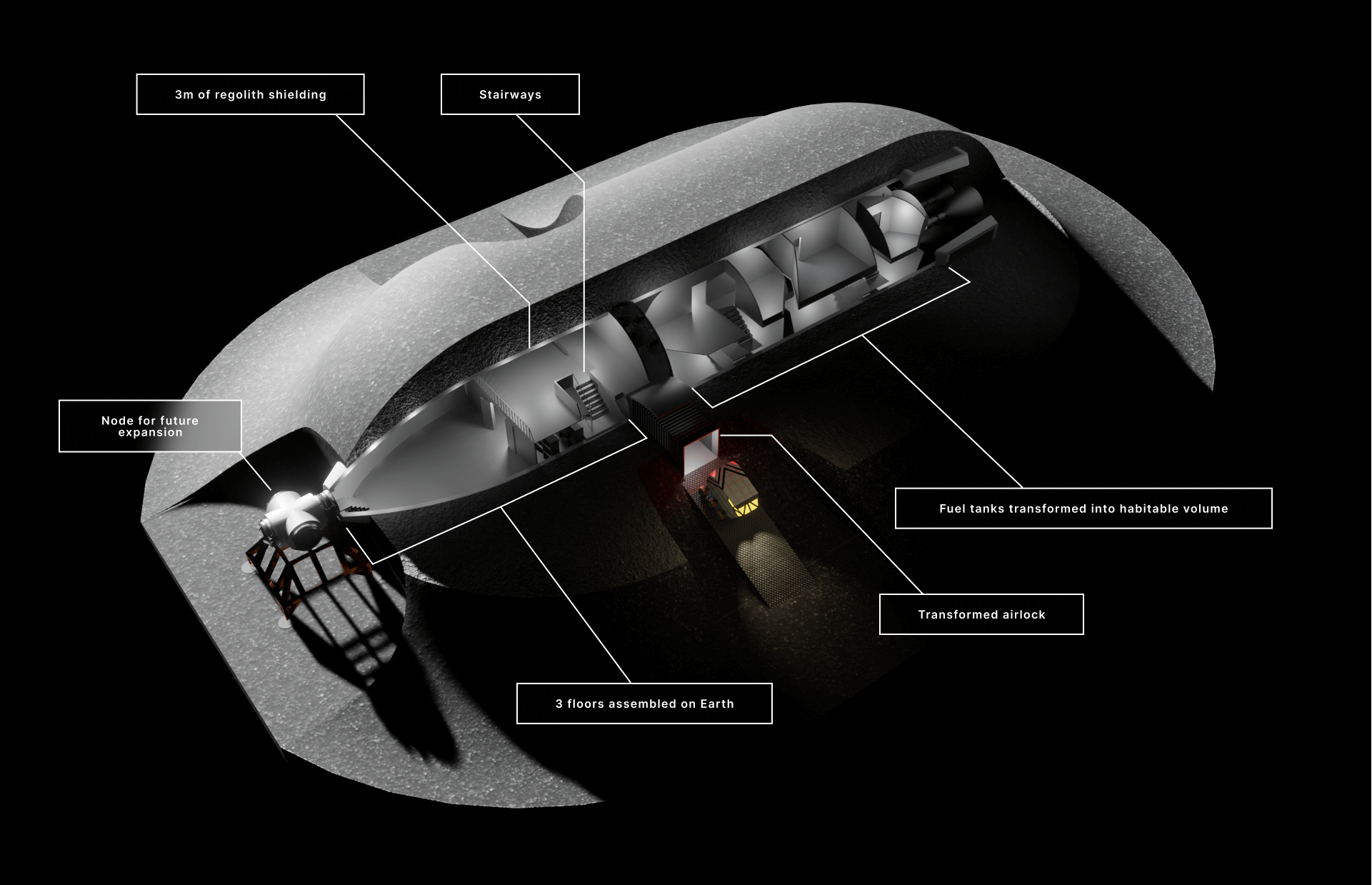

In order to maximize the utility of the volume, the selected orientation was a difficult one: by tipping the whole vehicle on the side, hazards to the crew could be diminished and the base could be further expanded.

However, how could you tip a 50 meter high starship?

The baseline Concept proposal

In order to assure all of the requirements for habitability, the design needed to include flooring, wall mounts, stairways, entrance hatches and airlocks.

Surrounding the base a 3m thick regolith layer would be deposited.

The transfer mission

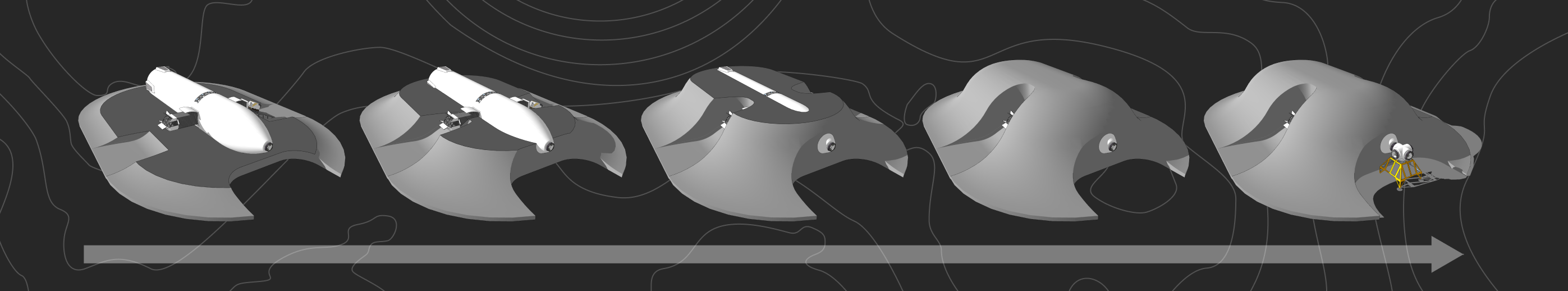

But how do you get a starship to the Moon? And, most importantly, how do you create a construction site on the Moon?

For that we need to consider a concept of operations derived from the state-of-the-art knowledge of how SpaceX Starships travel to the Moon.

For that we need to consider a concept of operations derived from the state-of-the-art knowledge of how SpaceX Starships travel to the Moon.

First of all, there were needed two mission starships (besides the fueling tankers), during two mission phases:

Phase 1 - Workshop vehicle launch

- SS Rosas transfer mission will launch the workshop vehicle that will land on the moon without a crew.

Phase 2 - Crew vehicle launch

- SS 501 transfer mission will launch the return starship with the crew that will continue the mission inside the habitat workshop (SS Rosas) already on the site.

Phase 1 - Workshop vehicle launch

- SS Rosas transfer mission will launch the workshop vehicle that will land on the moon without a crew.

Phase 2 - Crew vehicle launch

- SS 501 transfer mission will launch the return starship with the crew that will continue the mission inside the habitat workshop (SS Rosas) already on the site.

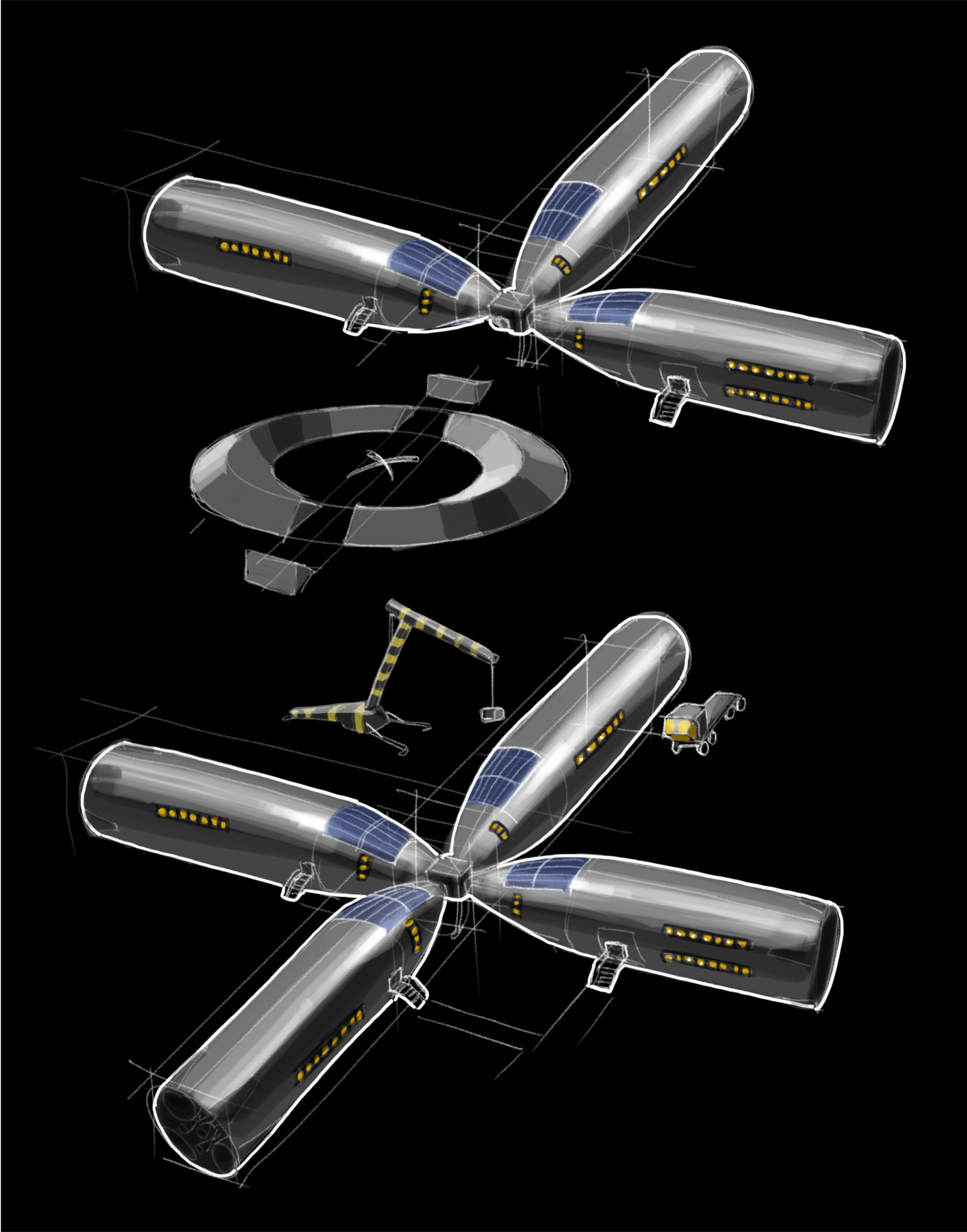

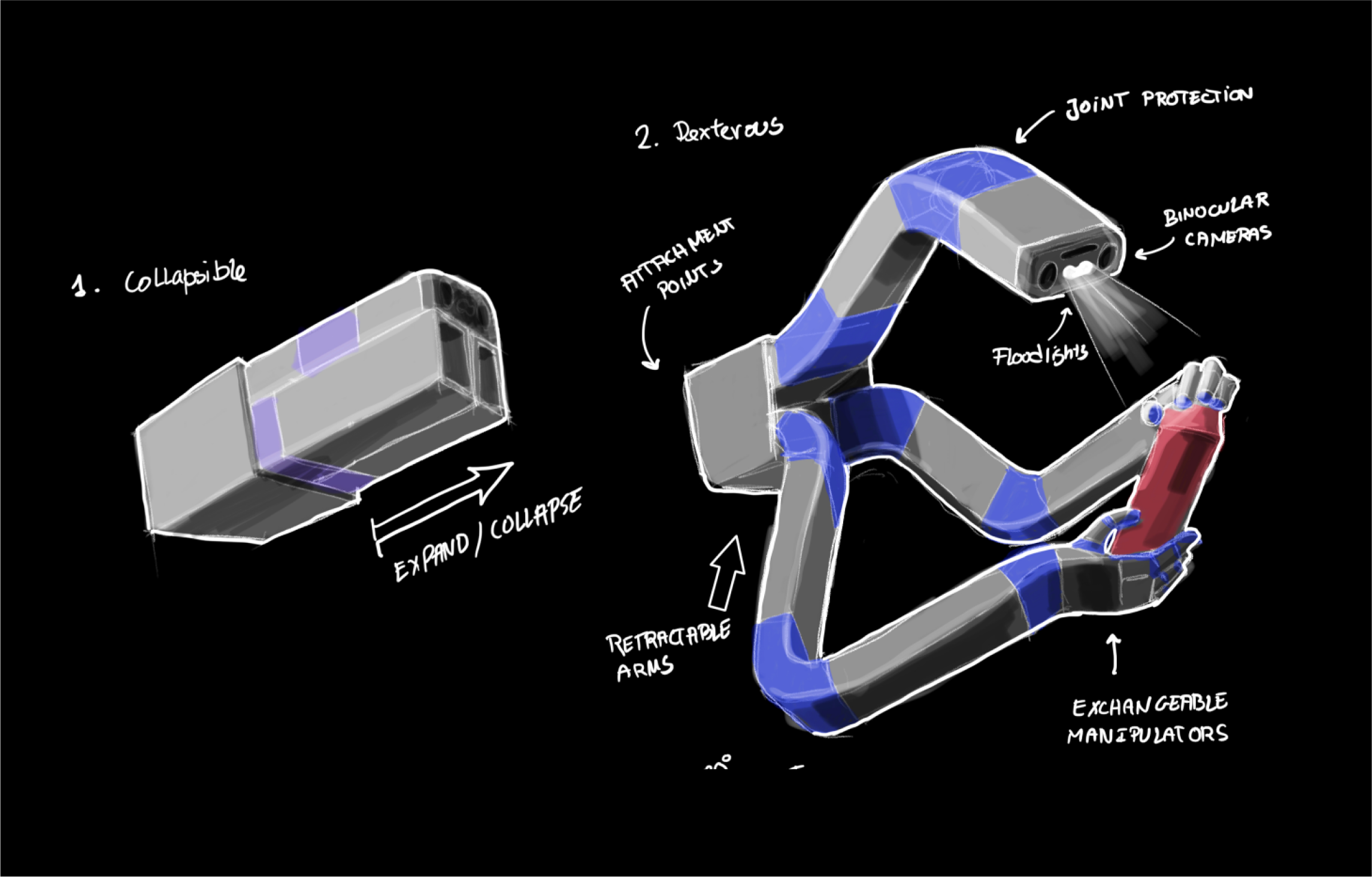

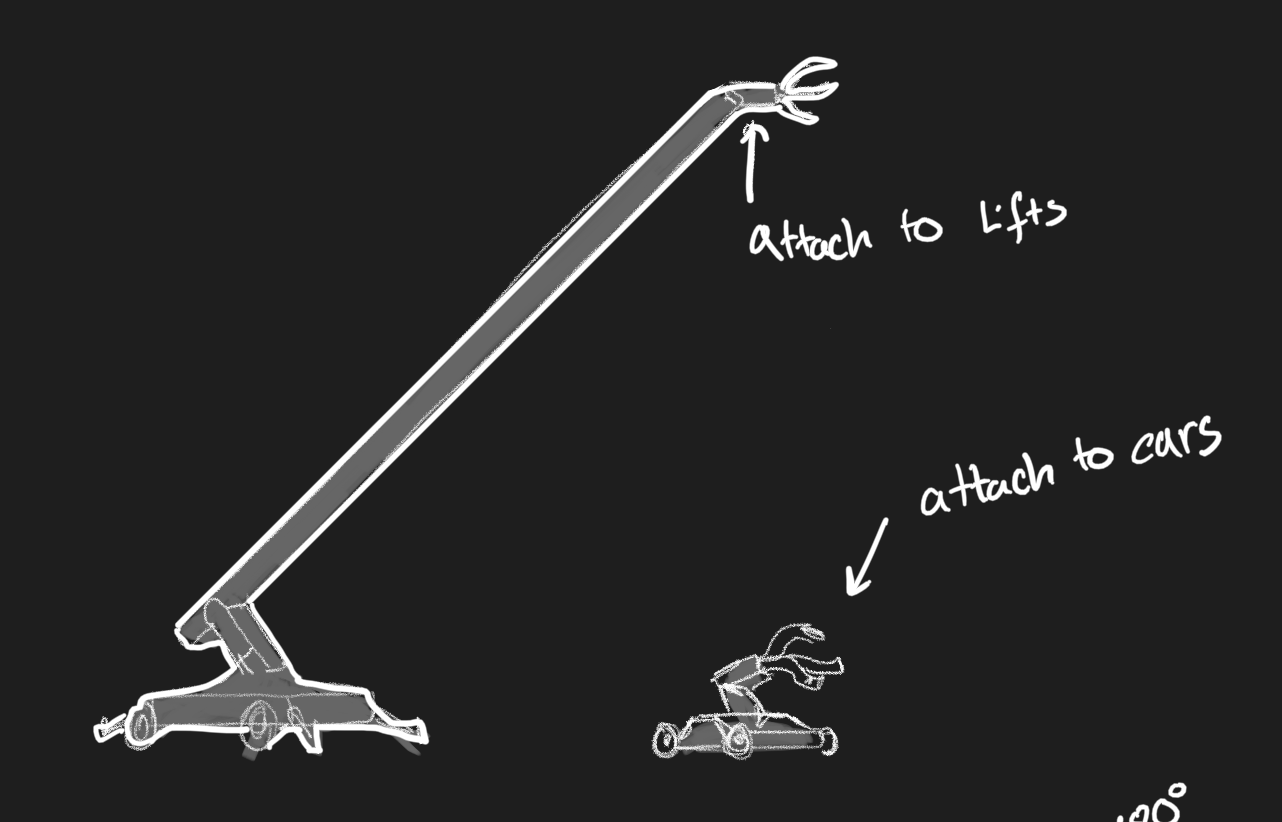

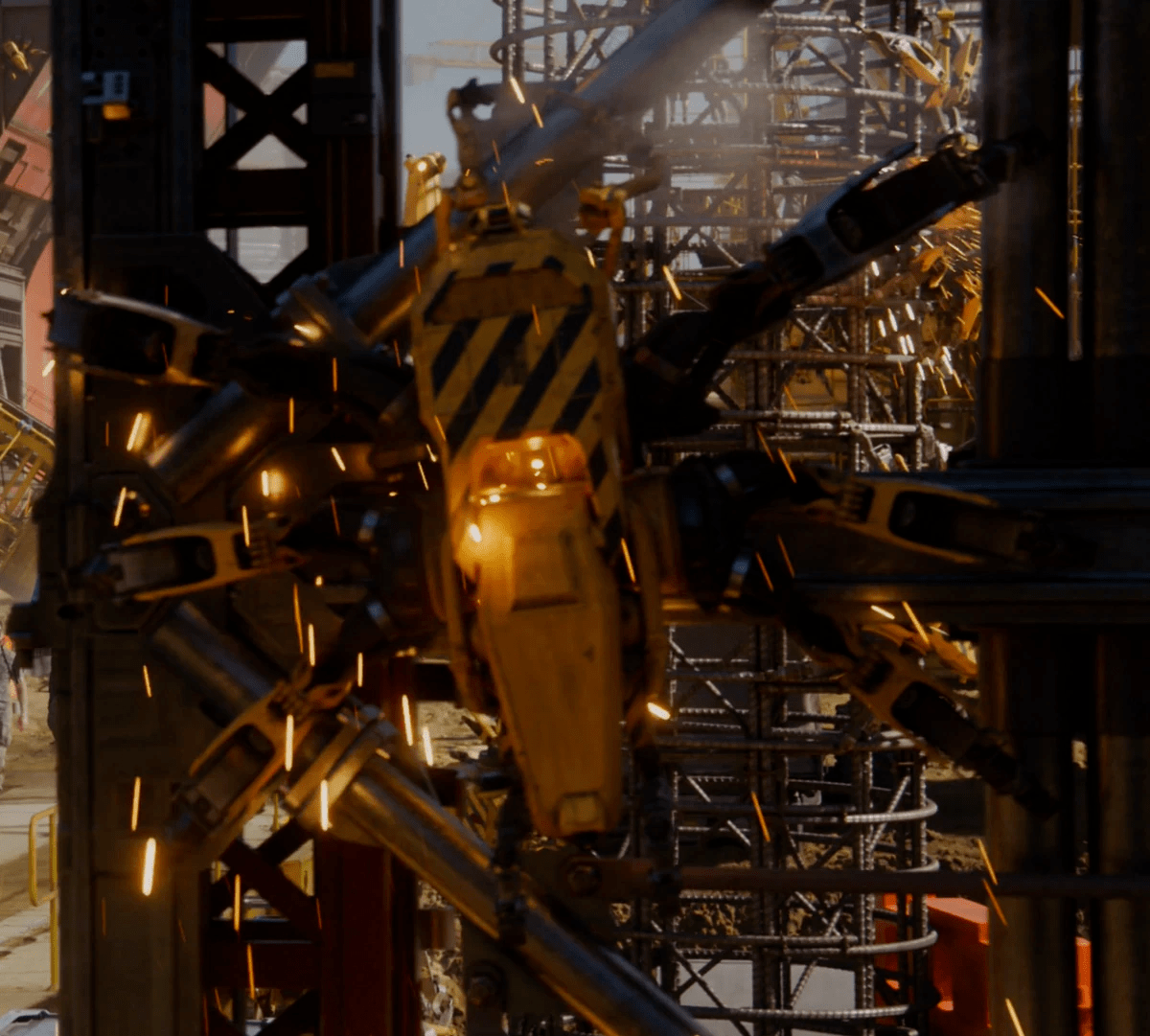

The MOROCAS: Modular robotic construction autonomous system

A modular, remotely operated, team of robots capable of preforming construction tasks.

This system was designed in order to reduce the amount of EVA time necessary.

The construction timeline

1. Horizontalization: After landing both starships, the base starship (future RosasBase) is horizontalized with the help of the MOROCAS system.

2. Volume connection: after the starship is horizontalized, the construction crew moves in and starts preparing the fuel tank transformation.

![Sequence of adapting the tanks into interconnected habitable volumes.]()

3. Interior installation:

Happening after the whole structure is stable and pressurized. The crew brings a series of moduler tiles to assemble the interior divisions of Rosas Base.

![Projection of starship-derived Moon Base's interiors.]()

Happening after the whole structure is stable and pressurized. The crew brings a series of moduler tiles to assemble the interior divisions of Rosas Base.

4. Regolith coverage

The lunar environment is a dangerous place. Micrometeors and radiation can be deadly to the whole crew and mission. This way a layer of regolith is deposited by the morocas along the duration of several weeksto months.

The lunar environment is a dangerous place. Micrometeors and radiation can be deadly to the whole crew and mission. This way a layer of regolith is deposited by the morocas along the duration of several weeksto months.

A window to our Home

On the side of the the starship, one of the airlocks is transformed into a cupola-style expandable volume. This enables a space for the astronauts to look at the exterior of the base, and, most importantly, to gaze at our Earth.

The OSCAR cupola is retractable. This way, the interior of the base can stay under the protecting regolith, while the viewing area can stay outside for short duration observations of the Lunar vista, and of Earth.

Photorealistic gallery

The team

List of all ISU SSP21 participants from Team Lunar that took part in the development of the project.

PARTICIPANTS

Adam Abdin 🇫🇷 Adina Godeanu 🇷🇴 Aiden O'leary 🇺🇸 Alan Garcia Juan 🇪🇸 Alberto Za 🇮🇹 Alexandra Sokolowski 🇩🇪 Damiana Irrera 🇮🇹 Charlotte Pouwels 🇳🇱 Emily Apollonio 🇺🇸 Gautier Bardi De Fourtou 🇫🇷 Gianmarco Ciocca 🇮🇹 Giorgio Lorini 🇮🇹 João Montenegro 🇵🇹 Karl Bolmgren 🇸🇪 Laura Pauzie 🇫🇷 Leonard Carl Luigi Lidgard 🇮🇹 Monica Ekal 🇮🇳 Ori Onn 🇮🇱 Shay Monat 🇮🇱 Stefan Amberger 🇦🇹 Zhuang Tian 🇨🇳

CHAIRS

Rob Postema Matthew Sorgenfrei Antonio Martelo Gómez

TEACHING ASSOCIATE

Xiaochen Zhang

A special thank you

In loving memory of Oscar Federico Rosas Castillo – an adventurous, spirited soul who brought us together and made our world a better place. We are better for having known you. May your light shine bright upon us until we see you on the other side of the stars.

Ad Astra.

Acknowledgements

ISU and Team Project Solutions for Construction of a Lunar Base wish to express their sincere appreciation to Lockheed Martin Corporation for its sponsorship of this project.

We would also like to thank the chairs and teaching assistants for their amazing support during this team project. They have been the key factor in supporting this team during the process and therefore the success of this lunar team report.

Lastly, we would like to thank the International Space University and SSP21 staff for making this year’s program happen, during the COVID-19 period and supporting the team in the best way possible.

On the news

Oct. 23, 2021

Report: Solutions for Construction of a Lunar Base (Starship as base structure)

(Read 20577 times)

Read more

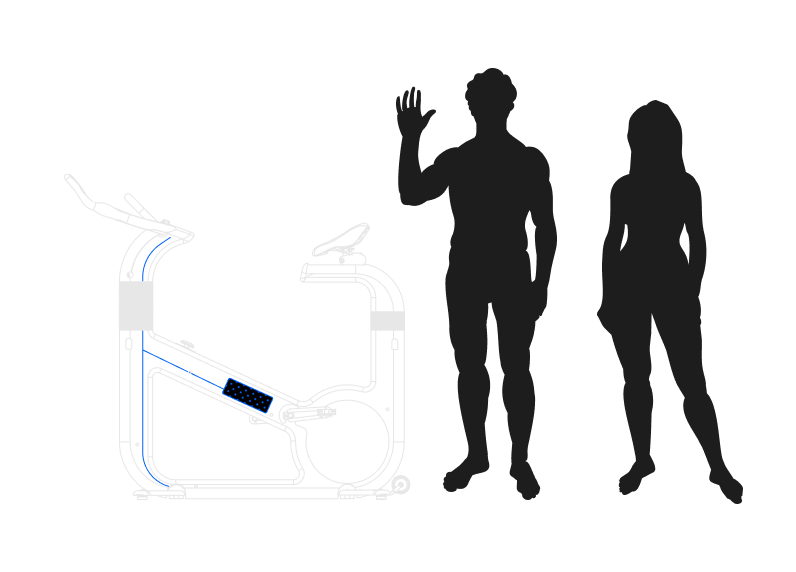

uBike

Smart. HomeFitness.

2010

uBike has a simple proposition:

Revolutionize how indoor cycling is experienced.

Merging advanced energy generation technology and the power of the internet-of-things, this sports center is the definite choice for the gym and the home.

Revolutionize how indoor cycling is experienced.

Merging advanced energy generation technology and the power of the internet-of-things, this sports center is the definite choice for the gym and the home.

With its advanced energy generation technology and integration of the internet of things, the uBike is able to provide a truly unique and innovative experience for users. The design process for the uBike began with a focus on functionality and convenience, with the goal of creating a product that was both easy to use and effective in helping people reach their fitness goals.

In the design of uBike, the goal was to revolutionize the way indoor cycling is experienced. With a focus on advanced energy generation technology and the integration of the internet of things, the uBike design team, consisting of myself and designer Gregorio Rodrigues, set out to create a sports center that would be the definitive choice for both gym and home use.

Starting with the mechanical engineering concept, we worked to create a functional design that would be both efficient and effective. From there, we moved on to the functional concept design, focusing on how the uBike would be used and what features it would need to have.

We fine-tuned the design, ensuring that it would be not only aesthetically pleasing but also functional and user-friendly.

The result of our efforts is uBike, a revolutionary design that is changing the way people experience indoor cycling. Whether you're looking to get in shape or just have some fun, uBike is the perfect choice for anyone looking to enhance their indoor cycling experience.

News

GPT for hardware Engineering

A workflow study.

Wednesday, Mar 8th, 2023

Generative Artificial intelligence (GenAI) has kick-started 2023 with a bang. But it has yet to prove its value for hardware engineers.

The limitation? Math and logic.

Although LLM based tools like OpenAI’s ChatGPT, Microsoft Bing, and Google’s Bard are proving the first mass use of AI’s generative powers, they have proven already that what they say is not to be trusted.

From what we can see, these tools still don’t work well with Math, logic, and facts. However, I have isolated three main great abilities for Engineering work:

- Generating good enough quality text, tables, lists and very basic code (reliably).

- Analyzing bodies of text. This is great for: summarizing text, tagging, semantic analysis, interconnecting information, and much more.

- Transforming text. That being style transfer (change the writing style, personality, cadence, language, etc. of a text), turning text into bullet points, tables, etc. Merging multiple sources of text.

Ok, I’m being exhaustive here, but this will be useful for the account below.

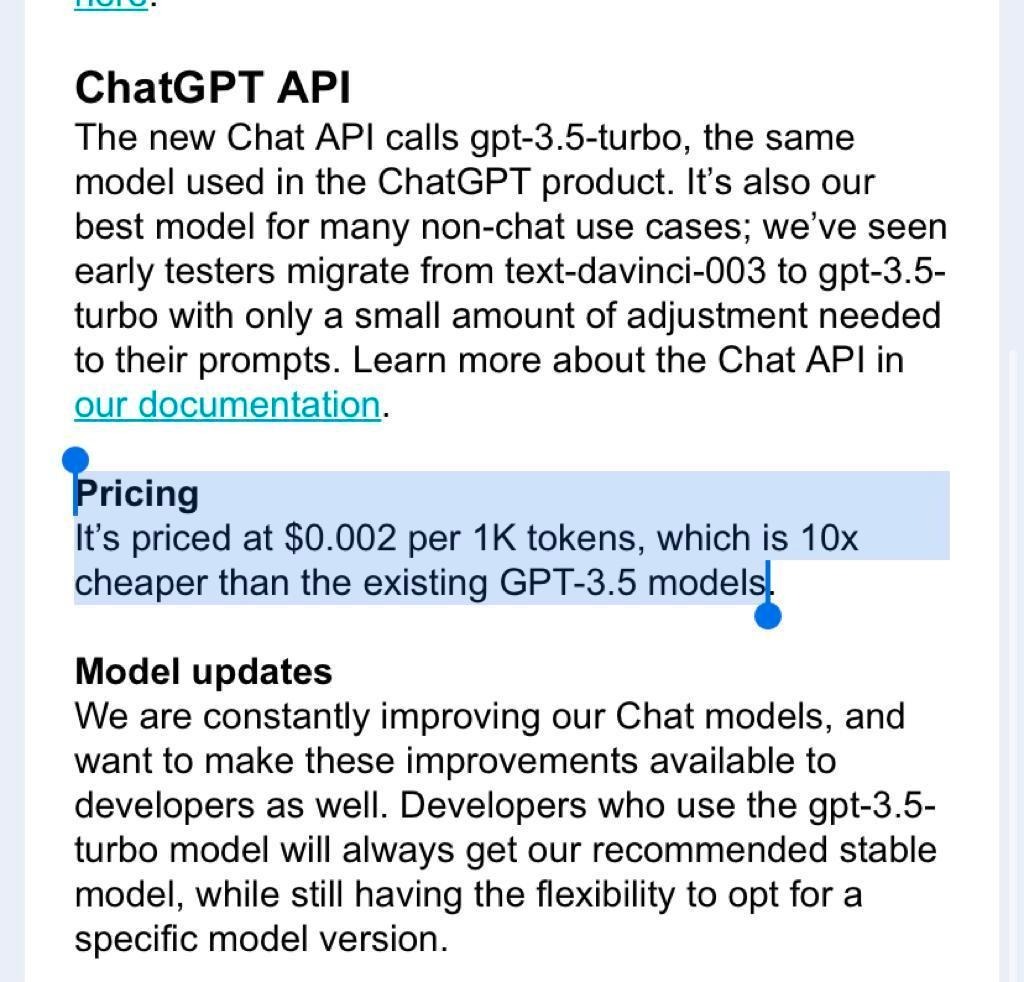

Cheaper APIs

Recently, OpenAI announced their GPT 3.5 turbo API. They called it ChatGPT API and can be found here: https://openai.com/blog/introducing-chatgpt-and-whisper-apis

Why is this important? Well: price.

Not only is this API accessing the same model used in the ChatGPT product, it is 10x cheaper than the other existing GPT-3.5 models.

GPT + Google Sheets

Turns out, the new API is already available in the GPTforWork Google Docs Add-On that you can find here: https://gptforwork.com/.

To get started, you need to:

- create an account at OpenAI

- Click View API key

- Create a new secret key

- install GPTforwork add-on on your Google Sheets + Docs

- Add the key

There are a few GPT Google Sheets functions. But we will mainly be using two: GPT() and GPT_TABLE().

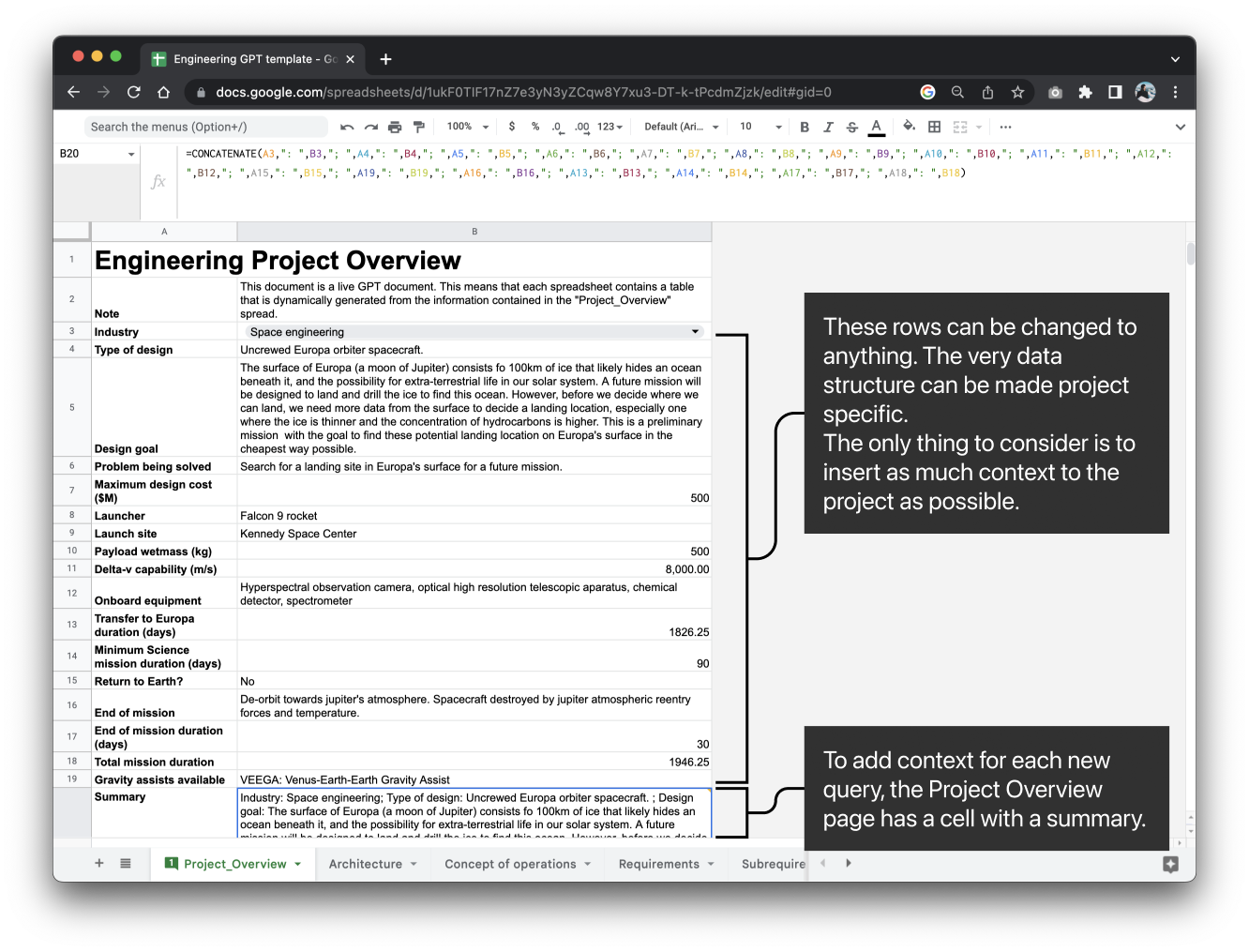

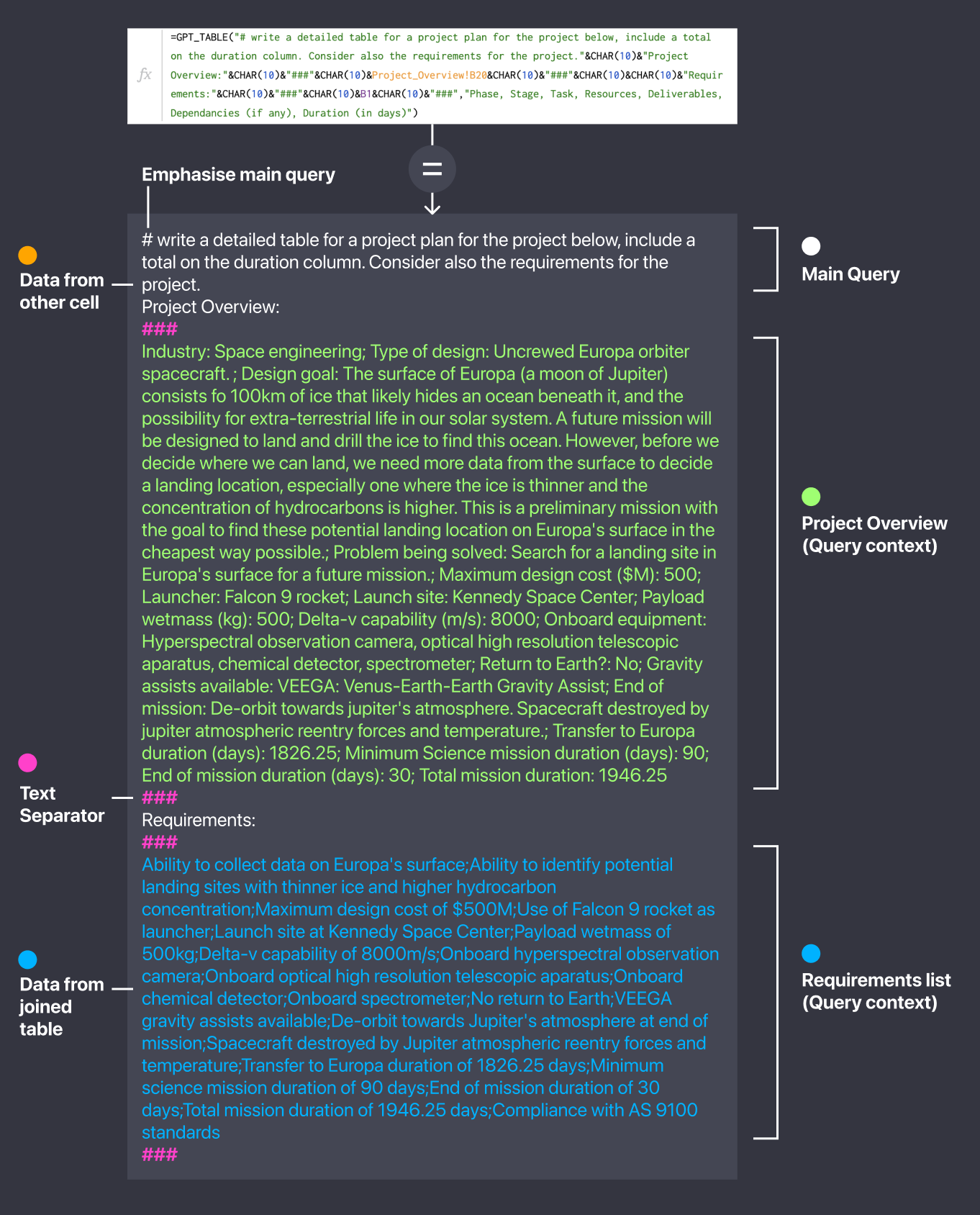

Desigining a space mission with GPT and Google Sheets

Be advised that this mission is a simplified version and would require many more iterations and detail. However, it can give you a glimpse of how fast one can build this type of documents.

So let’s begin. First let me be clear on the goals of this article, in fact there are two goals:

1. Design a space mission – an Orbiter Spacecraft that will search for landing and drilling sites on Jupiter’s Moon Europa.

So basically, we will be designing something analogous to the Europa Clipper mission. More on this real life mission here: https://europa.nasa.gov/.

This way, the Clipper Mission will serve as a reference for what this new mission could be. This will serve as the “source for fact control” for this AI experiment.

2. Create a reusable workflow – This one is important as ideally this workflow should be useful not only in other space mission designs but in other hardware industry projects such as:

- 🚀 space engineering

- 🎮 consumer electronics

- 🚗 automotive

- 🦾 robotics

- 🏗️ construction.

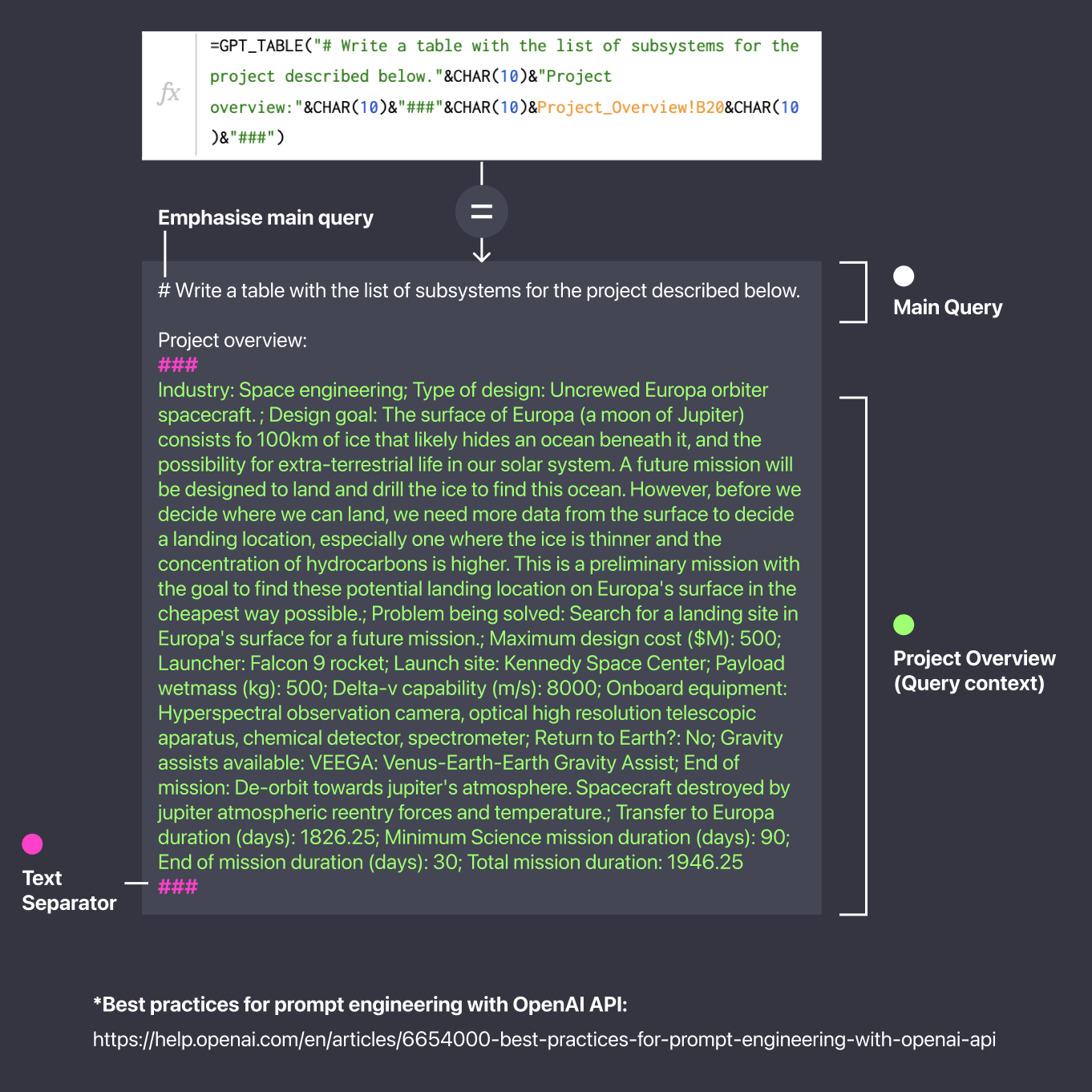

The template

The Project Overview

This page will work as a way to write in the context of the project. It will have a summary cell that will be inserted in every query we do to GPT. Yes, you read that well, since we are using GPT’s API, it doesn’t save context, so you need to explain everything in each query.

The cool part about using GPT is that we don’t need to preserve any type of data structure, as long as we provide enough information on the project. This is helpful if we want to use this page to describe a consumer electronics product, a robotic submarine, the design plan for a house with 3 bedrooms, etc.

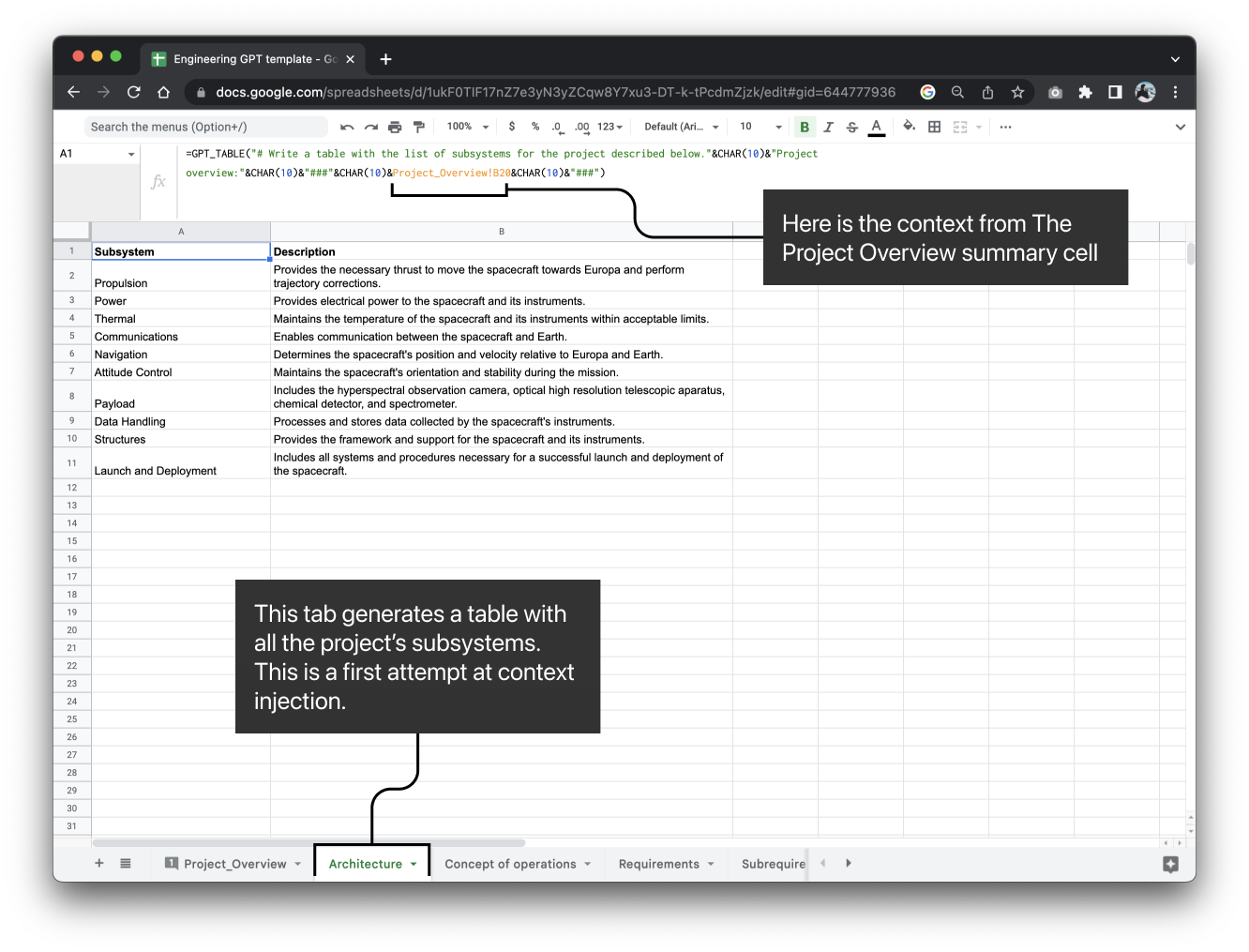

Architecture

Let’s use all that context from the project to ask GPT’s API to create an architecture layout for us.

We will use the GPT_TABLE() function. Here’s how it will work:

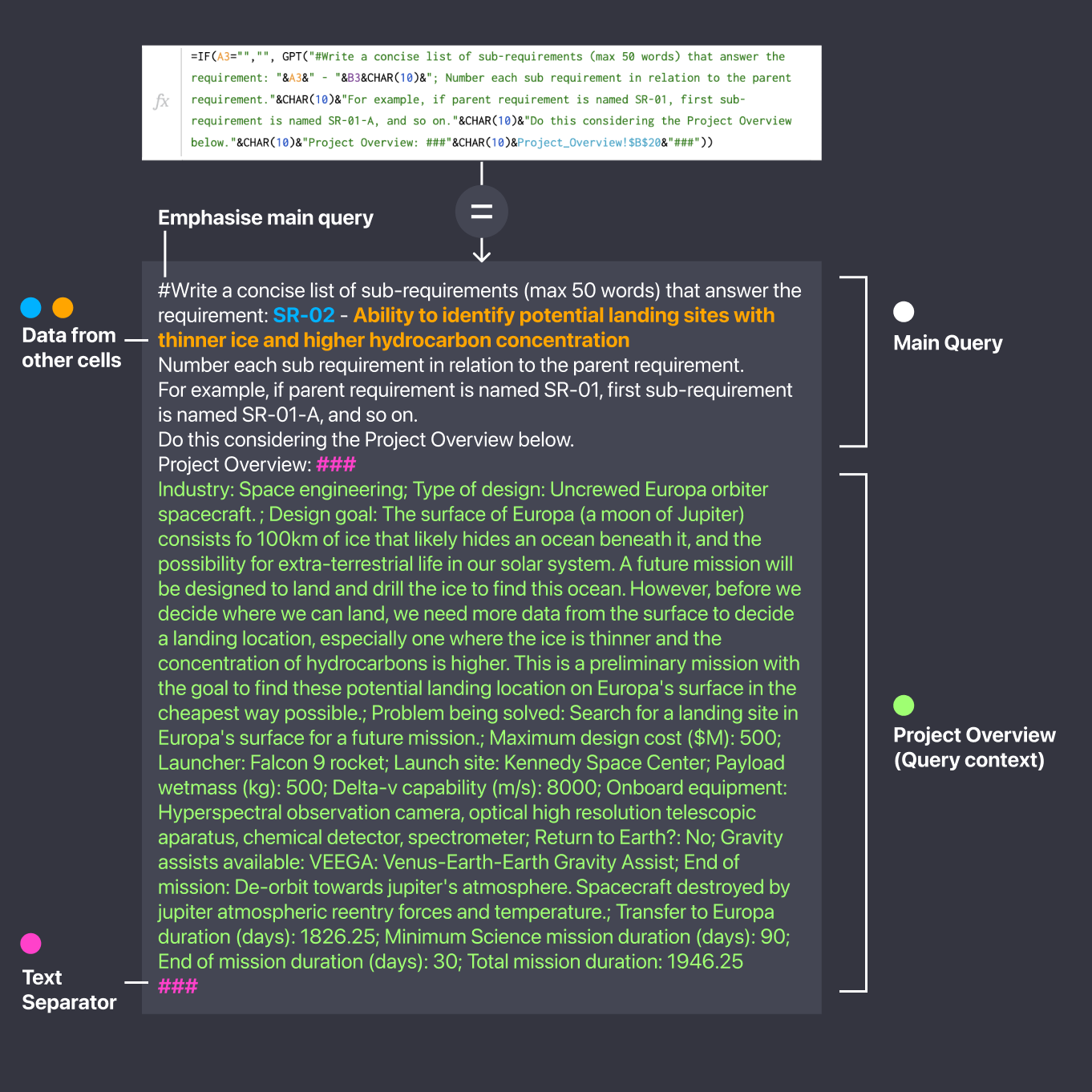

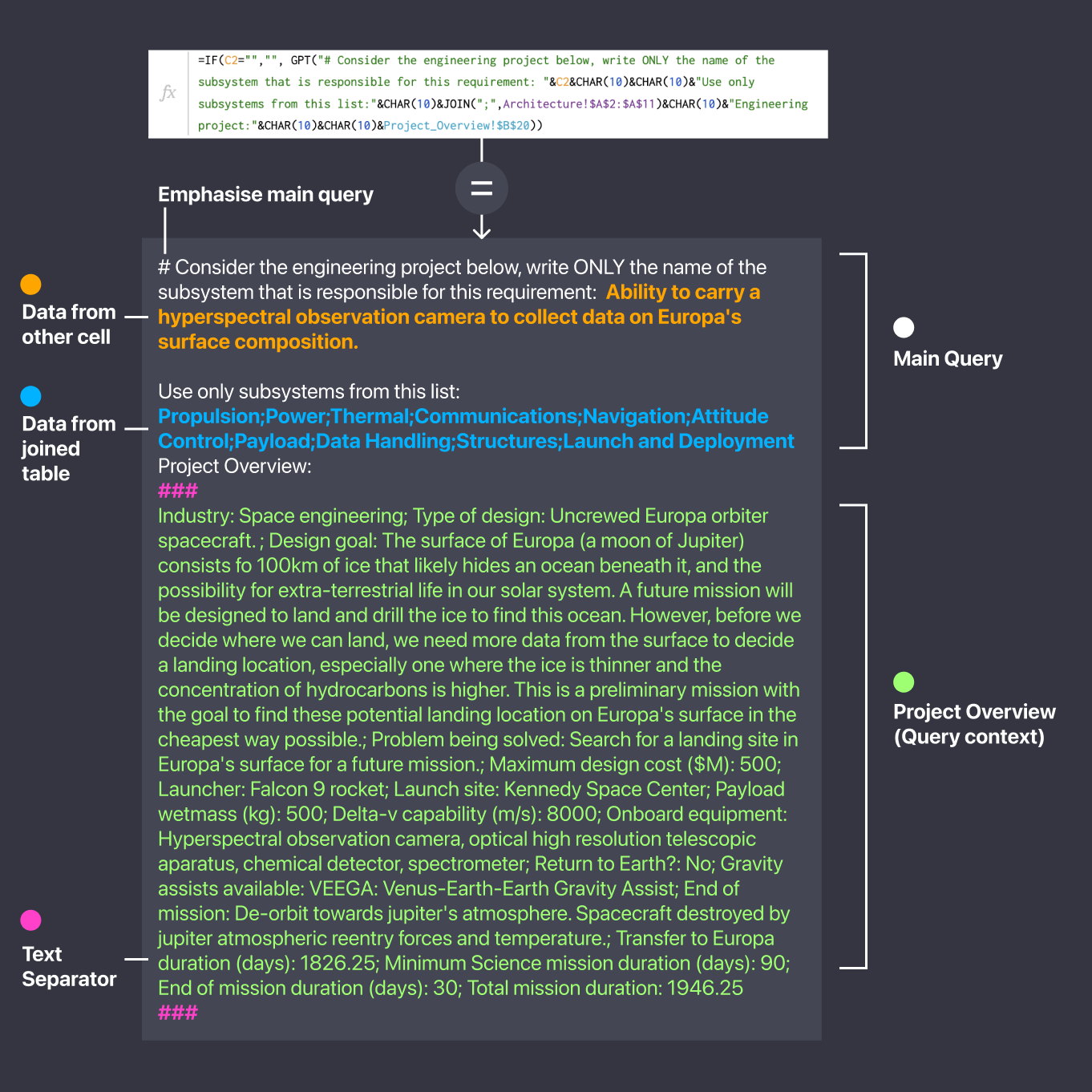

Requirements

One of the first activities that is needed for a Preliminary mission design report is a “System concept and requirements document”. We will go through this in a simplified way for illustrative purposes.

For a more detailed workflow, you can check out Valispace’s features here: https://www.valispace.com/ai/

Semantic matching

In my experience, this is a major GPT use-case: matching data with semantics.

Concept of operations

Now, as I mentioned before, GPT is not a source of science. And asking it for a CONOPs took some time, a many iterations. It would sometimes hallucinate strange actions like “Aero-break capture in Europa’s Atmosphere”. In the end, this type of data should not be generated by an AI (yet).

Sidenote

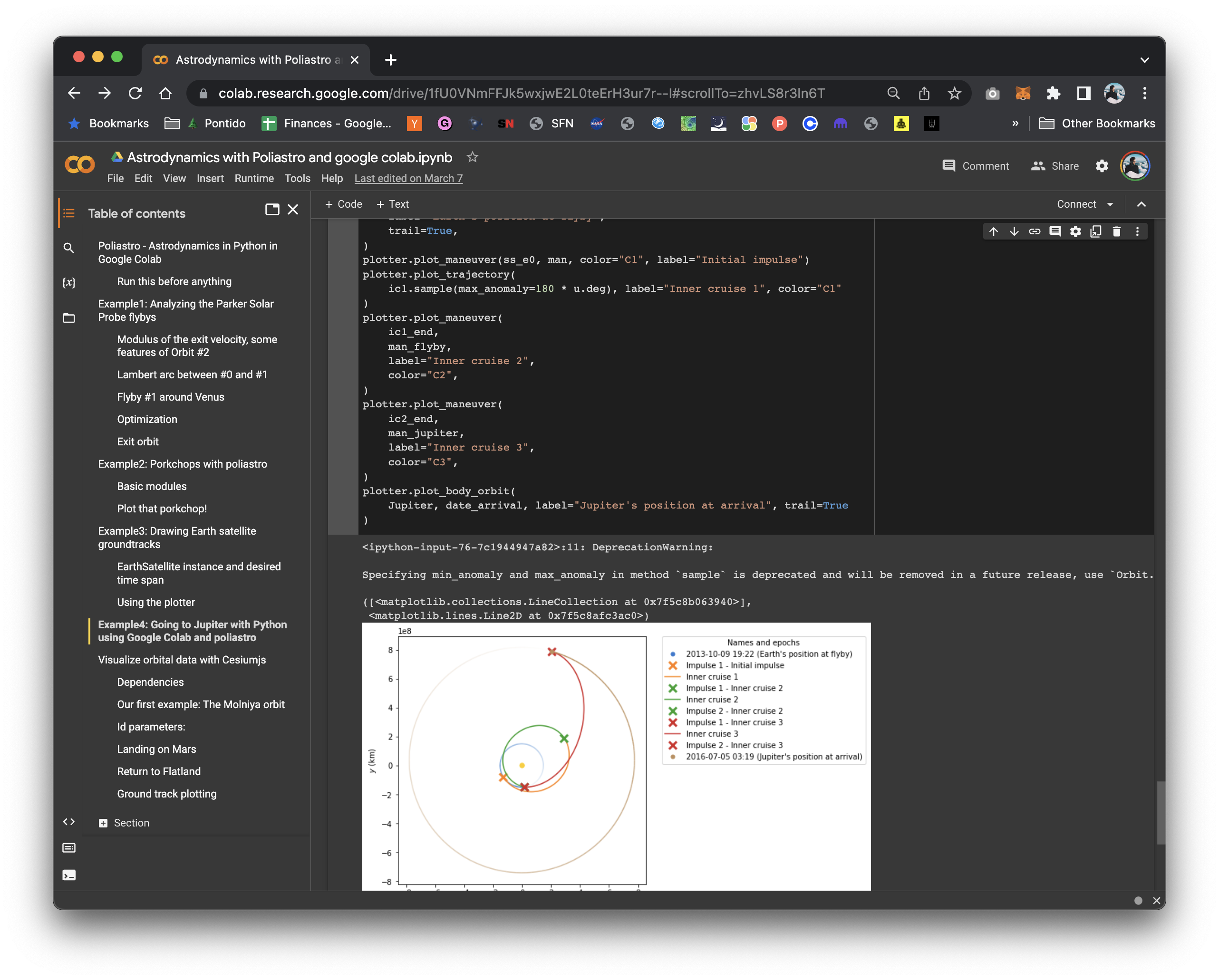

However, I have some ideas on how eventually training a GPT analog with libraries such as Poliastro can turn astronavigation into an automated task (Space Autopilot?).

Here’s a plan I made in Poliastro using ChatGPT as a reviewer for a flight plan to Jupiter using an Earth flyby for gravity assist (I used the dates from the Juno mission).

You can check out the Colab document here: https://colab.research.google.com/drive/1fU0VNmFFJk5wxjwE2L0teErH3ur7r--I?usp=sharing

Project plan

Alright, let's wrap this in a nice plan. This was the most expensive single query. Also, I did misspell “apparatus” and GPT just trusted me and replicated that word everywhere.

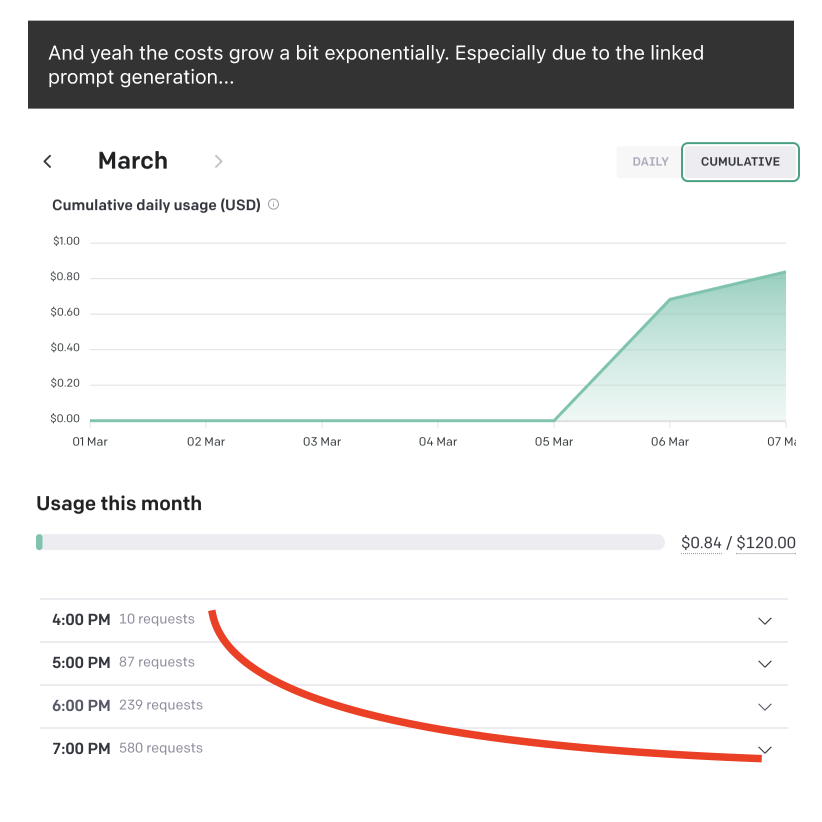

Cost analysis

Although OpenAI is doing an amazing job in scaling the GPT API and therefore lowering the price, it is still somewhat expensive.

In the end, working on this file cost me not much less than $1. Mainly because I used a few dozen of prompts, and because the prompts refresh when the document is reloaded.

As you can see below, the number of requests grew exponentially as the document grew in number of cells and iterations.

Things to avoid reducing cost:

- “Bake” your generations and add your prompt as a comment. This avoids the queries firing every time the document is reloaded or opened.

- Avoid “drag and drop”, especially when using linked queries (like the ones I did above), as your token usage will exponentiate.

Conclusion

GPT can definitely be used for engineering projects as a “delta” increase in productivity. It is great at extrapolating explanations from data and organizing explanations into data. However, we still need a mix between GPT and a rigid scientific, logical, and mathematical engine.

In the meantime, be my guest to copy this template, I’m looking forward to seeing if you find it useful and what you will use it for.

Oh, and feel free to reach out by clicking here!

© João Montenegro, All rights reserved.

How to model space travel with AI

How to design, develop and deploy complex simulations with the help of AI assistants.

Monday, May 1st, 2023

Are AI assistants just a fad, or can they truly help you build anything?

For the last few months, there's been a debate on whether these digital helpers are as powerful as they claim to be. Let’s explore just how much of a game-changer AI assistants can be, through the use-case of building a highly complex orbital simulator from scratch! Buckle up, because we're about to explore the cosmos through the lens of artificial intelligence.

If you're as passionate about spacecraft modeling as I am, you've probably heard of (or even used) popular space simulation programs like STK, GMAT, Kerbal Space Program, and the classic Orbiter Space Flight Simulator.

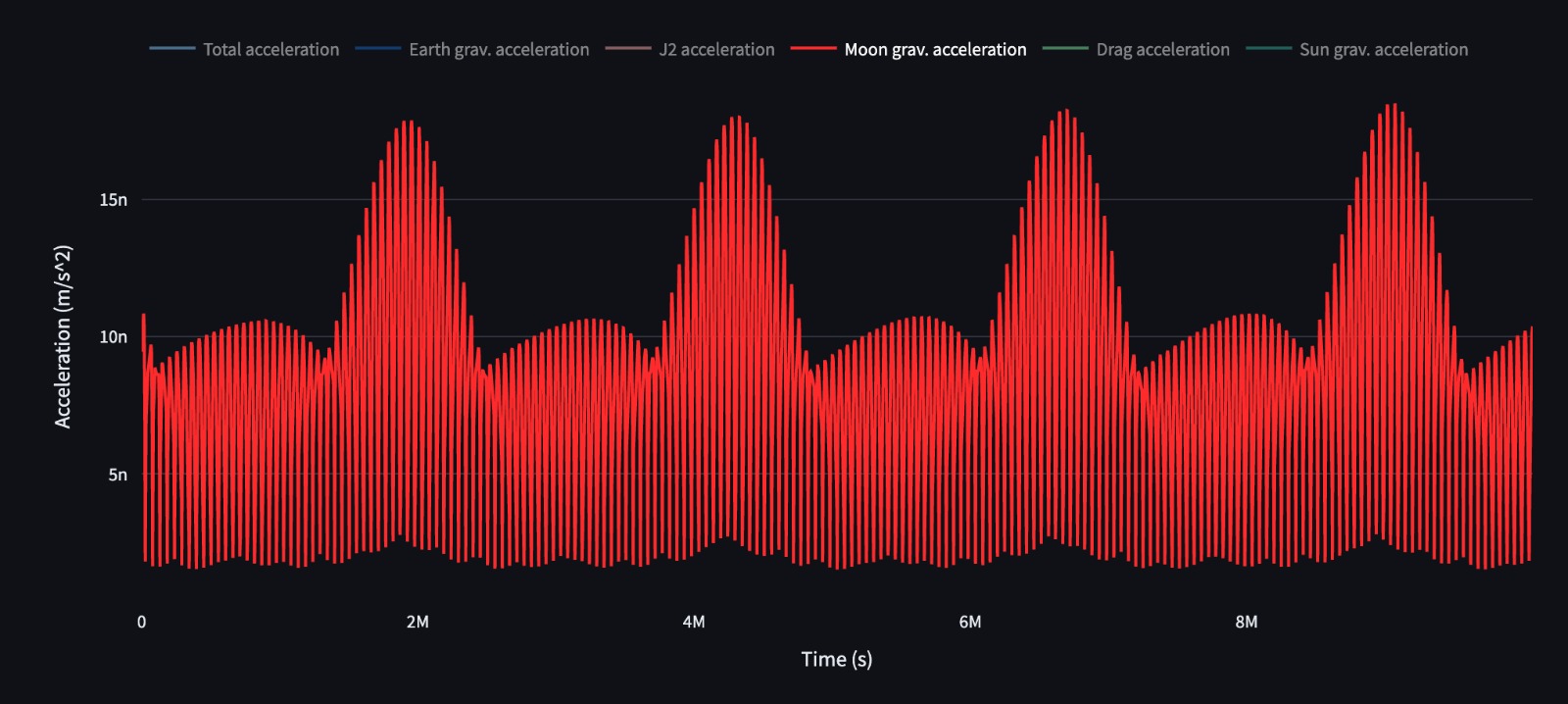

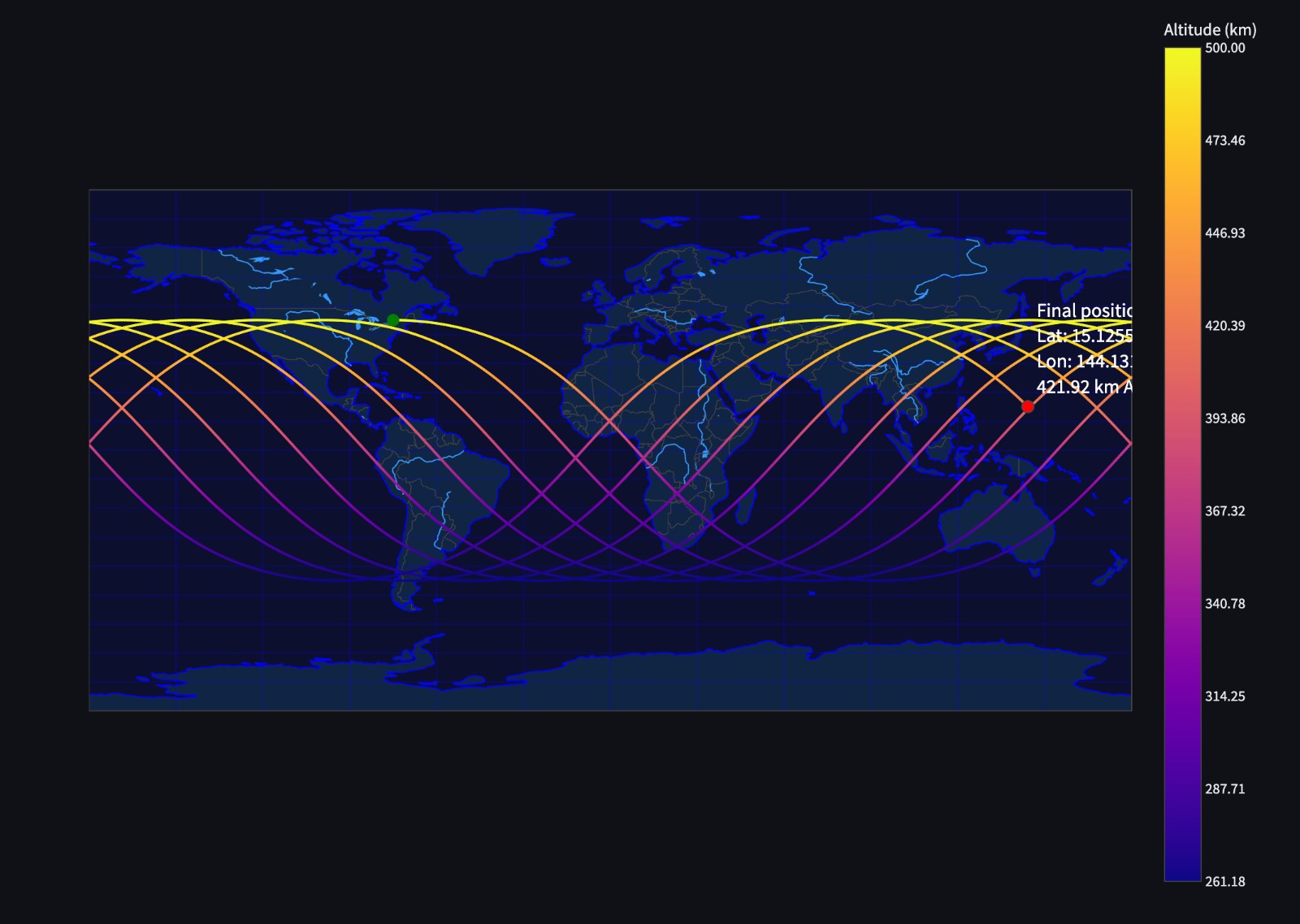

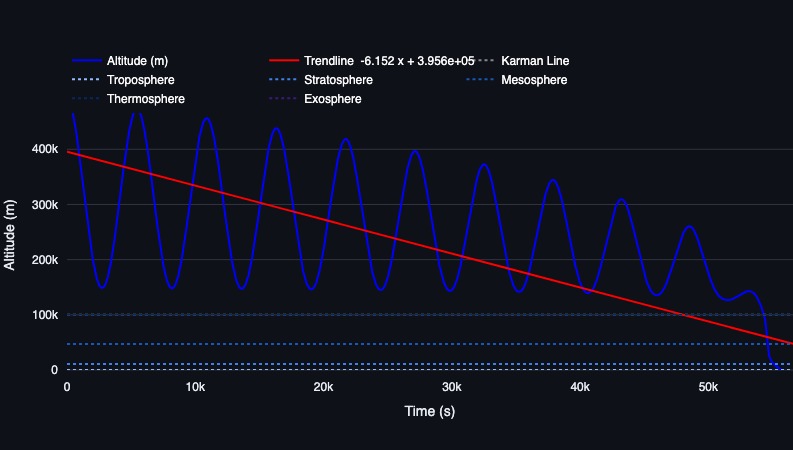

These simulation systems are usually very heavy as they integrate multi-body perturbations, atmospheric drag, etc.

So the code for these systems is complex, but could we build something like this with in 5 days? With some assistance form AI, yes.

This article is not meant to go into specifics of how such a system works. But as an analogy of how to build complex software with the help of AI.

Principles

The basis of being great at building software comes from the same principles, weather it is with the use of AI assistants or not. These principles, I believe, will just gain importance as we move into the future.

Build with Purpose

Focus on the end goal. Build a big vision. Make it actionable. Iterate.Having a great vision is not something that comes up in one time, unless you’re lucky. It’s something you perfect over time.

Keep your work under a compass. AIs can help you build this by creating flowcharts, maps, or summaries. But iterate on them.

Build with Usability

Focus on the end usability. If your building something build with the problem you’re solving in mind.Assistants can help in clearing up what are the main problems. But more important is to talk with the people you’re solving the problems in the first place.

Build with Knowledge

Know about what you’re building and, especially, who you’re building for.If there are things you need to learn, learn them fast. AI Assistants can help with that. Just type:

“Write me a tutorial on: {insert topic}”

The steps:

- Envisioning the Product

As a product developer with over a decade of experience, I know the importance of building a clear understanding of the product I want to create. In this case, I envisioned an orbital simulator capable of propagating spacecraft trajectories, detecting heating, drag, and reentry events, all while displaying complex visualizations in both 3D and 2D.

- Crafting the Simulator Pipeline

The goal was to use scipy's solve_ivp and iterate on an initial state vector through time. With each iteration, I computed various orbital perturbations, so I needed the system to be as lean as possible.

- Physics Modelling

I started by using astropy and poliastro's libraries but ended up rebuilding the equations on my side, which increased performance over 10x! Talk about efficiency!

- Visualization

I hacked Plotly like crazy to offer the best 3D experience possible in a low-code app like Streamlit. This included modeling Earth with its accurate physical properties, ephemerides, and various charts to break down data into comprehensible slices.

5. Optimization By harnessing the power of Python's high-performance numba compiler, I managed to reduce processing times another 10x-50x – perfect for running on Streamlit's cloud systems.

You can see and download the code in it’s repository or try it out online here.

© João Montenegro, All rights reserved.

The great inversion

How scalable down-mass capabilities will change the face of space travel

Monday, January 9th, 2023

Space travel has come a long way since the first crewed mission to the moon in 1969. In the past few decades, we've seen the development of reusable rockets, the growth of private space companies, and the establishment of the International Space Station as a hub for scientific research.

But one area that has yet to be fully explored is the potential for scalable down-mass capabilities in space travel. Scalable down-mass means transporting not just people and payloads but also resources and materials from space back to Earth and doing it in a way that can operate as efficiently as today's SpaceX rockets.

Currently, the vast majority of what we send into space stays there. This is partly due to the high cost and energy required to launch objects into orbit. It's also because we don't yet have the technology to safely and efficiently bring large quantities of material back down to the surface.

But as we look to the future of space exploration, down-mass capabilities could play a crucial role. Here's why:

- Sustainability in space: One of the biggest challenges of long-term space missions is cutting hardware development costs. This includes food, water, and other supplies, as well as spare parts and equipment for repairs. We can reduce each mission's cost by bringing resources back to Earth. This makes it possible to sustain larger and longer-term settlements in space.

- Utilizing space resources: Several resources available in space could be valuable for use on Earth. For example, the moon and asteroids contain a wealth of rare minerals and materials that could be used for everything from construction to medicine. With down-mass capabilities, we could potentially mine these resources and bring them back to Earth for use.

- Supporting space industries: As we expand our presence in space, we'll likely see the growth of new initiatives in orbit. For example, manufacturing in an area could be a way to take advantage of the unique conditions and resources available. With down-mass capabilities, we could transport the finished products back to Earth for sale.

- Reducing space debris: One of the significant challenges of space exploration is the issue of space debris. There are millions of pieces of debris orbiting Earth, and this poses a risk to both manned and unmanned missions. By bringing materials back to Earth, we can potentially reduce the amount of debris in orbit.

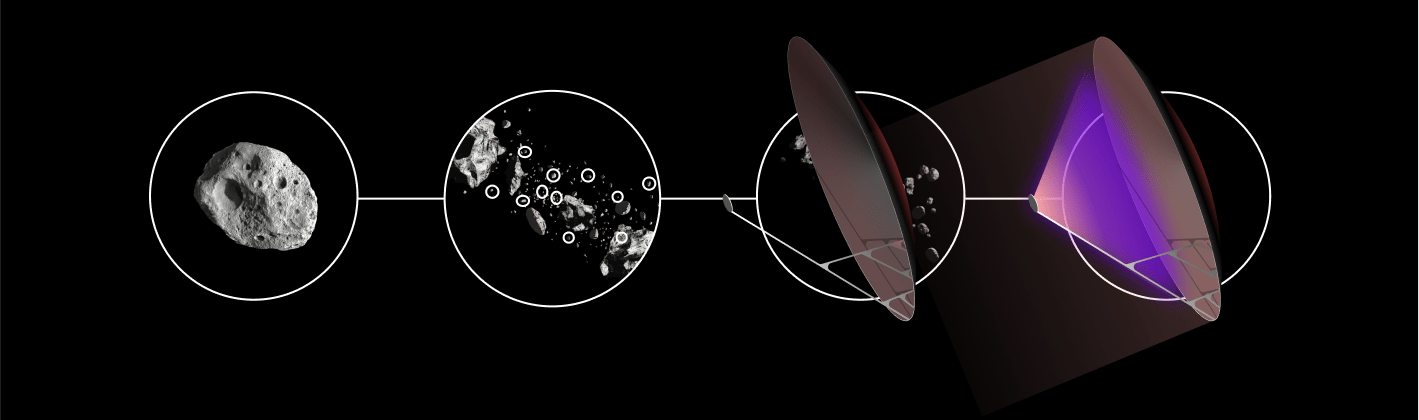

Use-cases for building the amazon prime of space

So how do we achieve down-mass capabilities? A few approaches are being explored:- Reusable third stages: One way to reduce the cost of space travel is to reduce hardware development and manufacturing costs. The upper stages of rockets are responsible for delivering payloads to their final destinations in space. Making these stages reusable allows us to bring cargo and materials back to Earth more efficiently. Companies like SpaceX, Stoke Space, Varda, and Blue Origin are already working on developing reusable third stages, and this technology could be a critical step toward down-mass capabilities.

- In-space manufacturing: Another approach being explored is in-space manufacturing. This involves using materials and resources available in space to create new products and components. For example, we could use 3D printing to produce spare parts for spacecraft or build structures in orbit. By manufacturing in space, we can reduce the need to transport materials from Earth and potentially pave the way for down-mass capabilities.

- Sample return: Asteroids and moons can provide resources for space travel. These celestial bodies are rich in various minerals and materials and could be mined for use on Earth or in space. While this technology is still in the early stages, companies like Astro Forge are working on developing the necessary technologies to mine asteroids for their valuable resources.

- Space station down-mass: Another approach being explored is using space stations as hubs for down-mass capabilities. These structures could serve as a waypoint for research payloads and space-products on their way back to Earth. Using space stations as a stopover point, we can potentially reduce the fuel and energy needed to return materials to the surface.

While there are still many challenges to be overcome in achieving down-mass capabilities, it's clear that this technology has the potential to revolutionize space exploration. By bringing resources and materials back to Earth, we can make space travel more sustainable, efficient, and cost-effective. As we continue to push the boundaries of space exploration, down-mass capabilities will likely play an increasingly important role in the future of space travel.

| Down-Mass Application | Market Opportunities | Problem Being Solved | Customer Examples |

|---|---|---|---|

| Resource extraction | Mining rare minerals and materials from celestial bodies for use on Earth | Sample return missions for science and technology development. | Space mining companies, space agencies |

| In-space manufacturing | Creating products and components using materials and resources available in space | Production of special application products in microgravity. These space-made products can be brought down to Earth or sold to the space economy in orbit. | Manufacturing companies, space agencies |

| Space debris removal | Removing debris from orbit to prevent collisions and reduce risk to spacecraft | Growing amount of debris in orbit poses a risk to manned and unmanned missions | Space agencies, satellite operators, Space DoD (Department of Defense) |

| Space station down-mass | Transporting mass from space stations | On-demand return from space of cargo and science | Private space stations, space agencies |

| “Just in time” orbital delivery | Transporting mass from LEO anywhere on Earth’s surface | Precision landing of special assets in short time. Applications range from disaster relief to military/defense logistics | Governments, space agencies, space DoD |

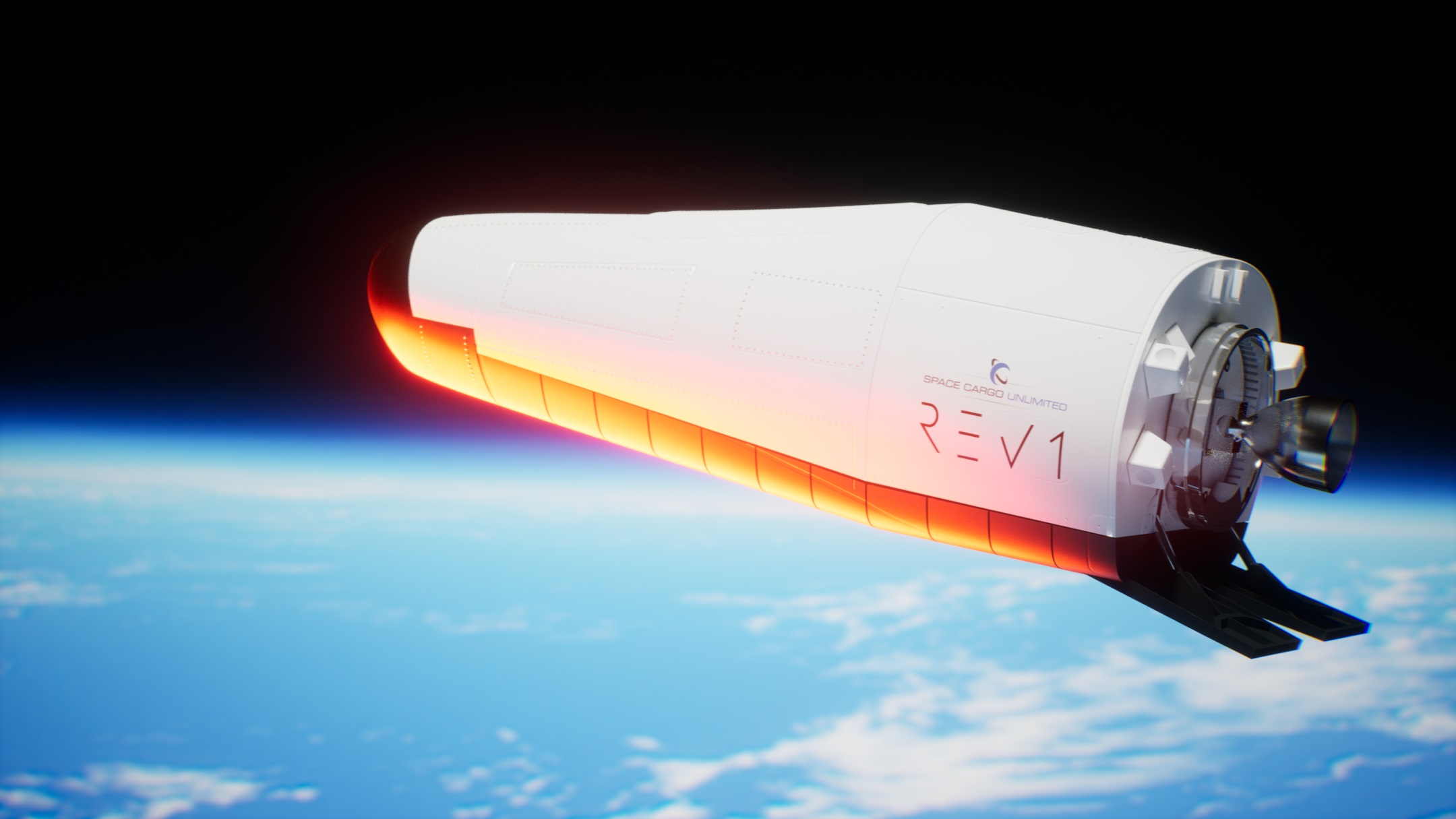

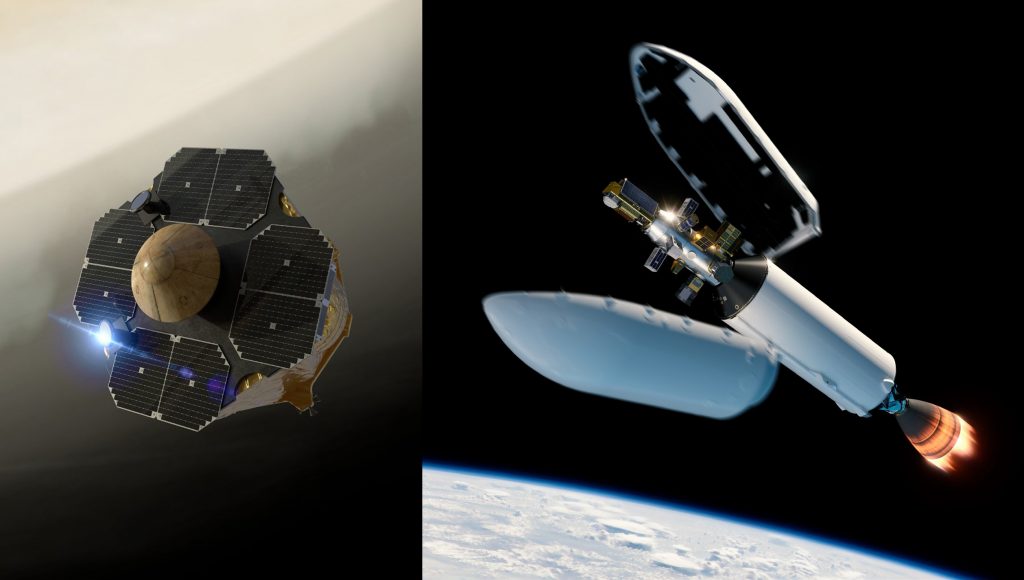

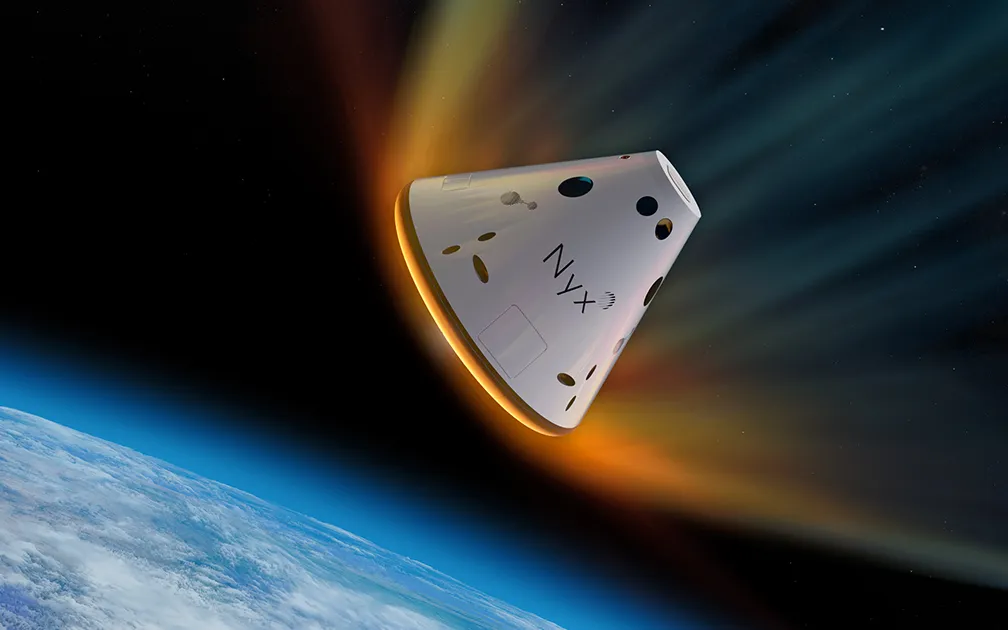

Current designs under development

Designs

Company list

| Name | Investment | Rounds | Description | Website | crunchbase |

| Outpost | $7,000,000.00 | Pre-seed, Seed | Outpost is the sustainable space company. We enable precision Earth Return of satellites and orbital payload missions. | http://outpost.space | https://www.crunchbase.com/organization/outpost-8590 |

| Space Forge | $10,800,000.00 | Pre-seed, Seed | Space Forge make super materials in space that cannot be made on earth. | https://www.spaceforge.co.uk | https://www.crunchbase.com/organization/space-forge |

| SpaceWorks | ? | ? | SpaceWorks is a seasoned space company with a branch developing reentry and descent systems | https://www.spaceworks.aero/flight/ | https://www.crunchbase.com/organization/space-works |

| Inversion | $10,000,000.00 | Pre-seed, Seed | Inversion builds space capsules to return cargo back to Earth for the commercial, civil, and defense industries. | https://www.inversionspace.com | https://www.crunchbase.com/organization/inversion-space |

| The Exploration Company | $6,800,000.00 | Pre-seed, Seed | The Exploration Company develops, manufactures and operates modular and reusable spaceships serving the needs of space stations. | https://www.exploration.space | https://www.crunchbase.com/organization/the-exploration-company |

| Varda | $51,000,000.00 | Pre-seed, Seed, Series-A | Varda is a space manufacturing startup that focuses on creating products in space for terrestrial applications. | https://varda.com | https://www.crunchbase.com/organization/varda-ba64 |

| Elevation Space | $2,431,532.78 | Seed | Elevation space is developing space manufacturing and reentry systems | https://elevation-space.com/ | - |

| Klaus Space Transportation | ? | ? | A sustainable space company focused on recovering space assets, such as a second stage recovery ballute. | https://www.klausspacetransportation.com/ | - |

| In Orbit Aerospace | ? | TechStars | In Orbit is focused on space manufacturing in a very similar way to Varda. Developing their own orbital factory and recovery capsule. | https://www.inorbitaerospace.com/ | - |

| Reorbit | $789,000.00 | ? | Reorbit is developing a set of technologies to make spacecraft platforms modular and configurable to accommodate different types of payloads, and equipped with built-in autonomous orbital capabilities and a software-defined architecture. | https://www.reorbit.space/ | https://www.crunchbase.com/organization/reorbit |

| Space Cargo Unlimited | ? | ? | Space Cargo Unlimited is developing an orbital factory and recovery vehicle inspired in the Space Rider Design | https://space-cu.com/ | https://www.crunchbase.com/organization/space-cargo-unlimited |

References

- "The Case for Space: How the Revolution in Spaceflight Opens Up a Future of Limitless Possibility" by Robert Zubrin (2012)

-

"Asteroid Mining 101: Wealth for the New Space Economy" by John S. Lewis (2012)

-

"Space Manufacturing: Materials Processing in Space" by David A. Hardy (1982)

-

"Reusable Launch Vehicle: Technology, Development, and Operation" by Dietrich K. H. Jens (2008)

-

"Space Solar Power: An Introduction to the Concept, Technological Challenges, and Potential" by Paul Jaffe and Joel Sercel (2016)

-

"Space Manufacturing" by the NASA Glenn Research Center: https://www.nasa.gov/oem/inspacemanufacturing

- Astroforge https://www.astroforge.io/

- Inversion https://www.inversionspace.com/

- Space Cargo Unlimited https://space-cu.com/

- Varda https://varda.com/

- Stoke Space https://www.stokespace.com/

- The Exploration Company https://www.exploration.space/

-

"Reusable Rockets" by SpaceX: https://www.spacex.com/reusability/

- "Space Debris" by the European Space Agency: https://www.esa.int/Safety_Security/Space_Debris

- In-Space Manufacturing & Space Economy https://www.factoriesinspace.com/

© João Montenegro, All rights reserved.

How to go inter-stellar

The longtermist way of spreading consciousness throughout the galaxy

Monday, January 9th, 2023

Interstellar distances are mind-bogglingly large – so large that it's almost impossible for our brains to even wrap around them. Just a trip to our nearest star would take hundreds of thousands of years in the fastest spacecraft we've ever designed, let alone colonizing the entire galaxy. And unfortunately, the nearest systems to us – like Alpha Centauri and Proxima – are likely inhospitable for the same reasons we might not find another Earth within a 30 light-year radius: super flares and sterile multi-sun star systems.

But here's the thing: our Milky Way galaxy is around 80-100 thousand light-years across and contains around 400 billion star systems. That means there is likely an ocean of potential new homes out there, just waiting for us. The “only problem” is crossing the vast abyss of interstellar space.

While we're used to seeing interstellar travel in science fiction, our current understanding of physics simply doesn't allow us to reduce the duration of these trips. In fact, some have even suggested that interstellar flight might be the Great Filter preventing galactic civilizations from developing. But what if we were to embrace sub-light travel? What if we take a long-term view on galactic colonization?

Turns out, there are already many designs for sub-light ships floating around. These ships would, however, not be able to send living adult humans due to the mass budget being too high. Instead, we might consider a way of bringing the least amount of mass possible. One recently proposed interstellar ship, by the Breakthrough Starshot Project, would consist simply of a single chip propelled by overpowered lasers.

But what if we took this idea a step further and considered sending just human consciousness to another world? Let's merge two ideas: the Von Neumann interstellar self-replicator and the Breakthrough laser.

The mind-ship

Here's how we could send our consciousness accross the galaxy. A sub-light craft carrying self-replicating machinery would be deployed from Earth to a nearby star system. After thousands of years of travel, it would turn retrograde and start decelerating until it reached the new star system's asteroid belt. The sub-light ship would then attempt to find a 16 Psyche analog planetoid, as these would be excellent sources of metal.

Deploying a small cluster of Von Neumann replicator bots, the planetoid would be mined, and the cluster would build a large high-gain antenna and a series of factories. After finishing the antenna, a transmission would be sent back to Earth, indicating the mission was successful.

After a few years of light travel, the transmission would reach Earth, which would trigger an automated action: the transmission of a snapshot of all human consciousnesses at that time. The transmission would then reach the Von Neumann cluster, which was already constructing robotic bodies and ships from the metal planetoids.

And then, the cycle would repeat. A new sub-light ship and super laser would be developed and launched to the next system, and so on. According to the Von Neumann probes theory, the colonization of the whole galaxy could happen in over half a million years.

Now, this might seem like a long time to us, but remember: we're talking about interstellar distances here. And even though half a million years might seem like a drop in the ocean on a cosmic scale, it's still an incredibly exciting prospect. Just think about it: the possibility of human consciousness traveling to and colonizing new worlds, all while humanity would continue living their lives on Earth. A literal interstellar copy-paste.

The ideas of sub-light travel and sending human consciousness across the dephts might seem far-fetched, but it's not entirely out of the realm of possibility. And even if we can't achieve it in our lifetime, it's still worth considering and exploring. Who knows what kind of advances in technology and science we might make in the next few centuries that could bring us closer to achieving this goal?

But it's not just about the technology. There are also ethical and philosophical considerations to take into account. How would we choose which consciousnesses get sent? Would it be based on merit, or would it be a random selection? And once the consciousnesses are transmitted, how would they exist in the new world? Would they be able to interact with their surroundings in the same way that we do on Earth? These are all questions that will need to be addressed as we continue to explore the possibility of this type of interstellar travel.

One thing is for sure: the idea of interstellar colonization is both thrilling and daunting. It will require a lot of collaboration and creativity from scientists, engineers, and philosophers. But the rewards would be huge. The opportunity to expand our reach beyond our own solar system and potentially find new homes for humanity is a tantalizing prospect. So let's embrace sub-light travel and take a long-term view on galactic colonization. The galaxy is waiting.

References

- “Technology to Make Interstellar Missions Possible and Affordable”, August 16, 2022 by Brian Wang

- "The Alpha Centauri System: A Review of Its Habitability" by Belinda Nicholson, Journal of Astrobiology

- "Interstellar Colonization: The Challenges and Possibilities" by Mark G. Martins, The Space Review (website)

- "The Feasibility of Sub-Light Interstellar Travel" by John C. Mankins, Aerospace America

- "Exploring the Possibility of Von Neumann Probes for Interstellar Travel" by R. Michael Minch and John C. Mankins, The Journal of the British Interplanetary Society

- "The Breakthrough Starshot Project: A New Approach to Interstellar Travel" by Philip Lubin and Abraham Loeb, Scientific American

- "The Von Neumann Interstellar Self-Replicator: A Review" by Elizabeth L. Hill, The Journal of the British Interplanetary Society

- "Exploring the Feasibility of Sending Human Consciousness for Interstellar Travel" by Susan Schneider, The Journal of Astrobiology

- "Interstellar Travel and Galactic C

olonization: A Review" by John G. Molloy, The Space Review (website) - "Sub-Light Interstellar Travel: Possibilities and Challenges" by Richard Obousy, The Journal of the British Interplanetary Society

© João Montenegro, All rights reserved.

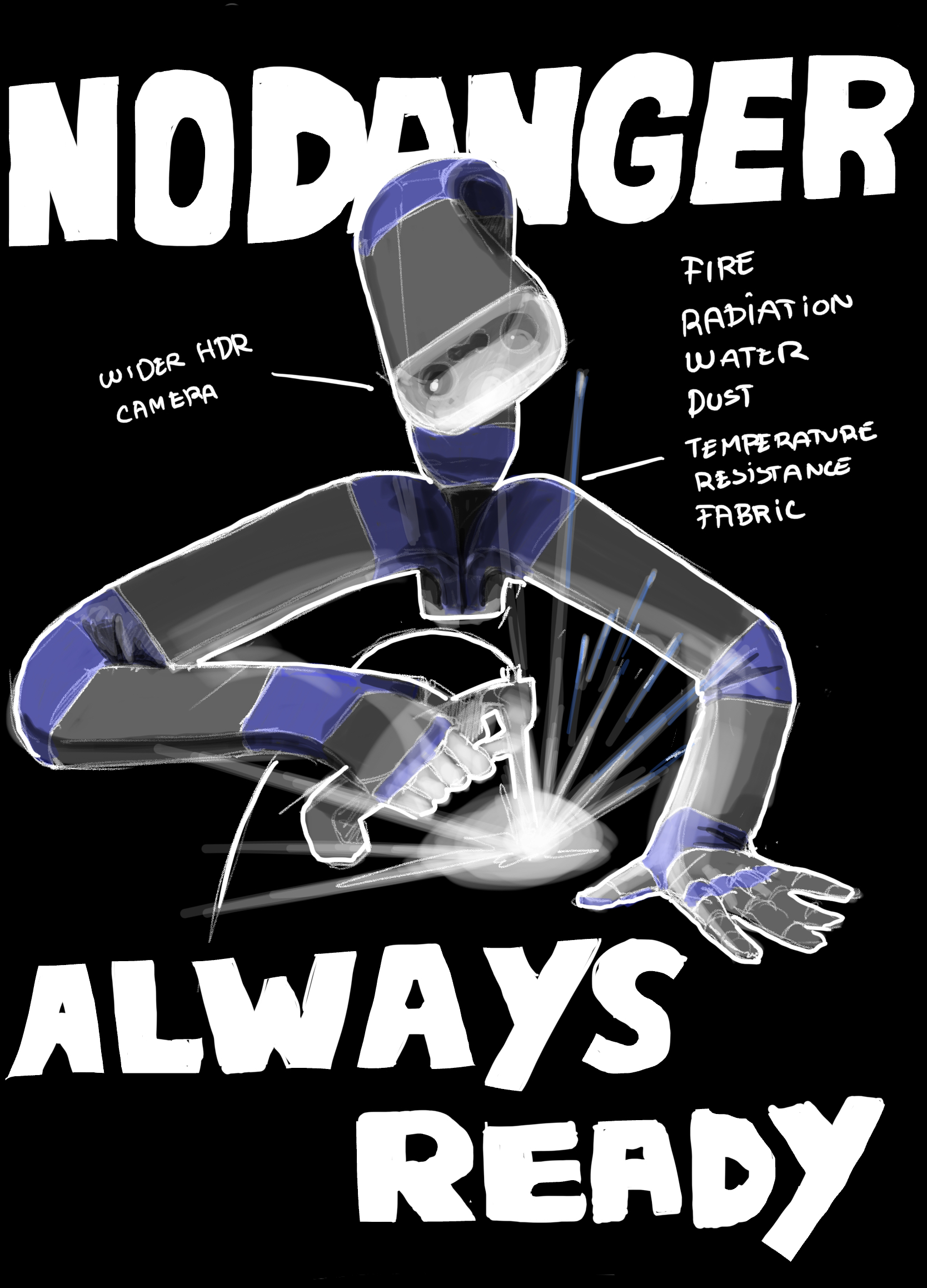

Avatars for Every thing

How the future of work be a mix of gaming and robotics

Tuesday, January 10th, 2023

America desperately needs 1 million more construction workers. In the rest of the world, this problem is even more significant.

The incentives to work in the construction industry are disappearing as Low-skill service jobs are growing (like uber driving, food delivery, etc.). These low-skill jobs are already competing with construction. That's because construction jobs have a 30-40% higher rate of injury and death than any other job in the world. This trend will only continue.

As we saw in the QATAR world cup, the construction industry is filled with abusive employment conditions and even slavery. However, the construction industry is essential for civilization to flourish. We must consistently renew homes, build new ones, improve infrastructure, and build in dangerous environments. And currently, the only direction for the market seems to be the increase in prices of all construction.

The construction industry is just an example of a more significant trend. The same can be said for agriculture, policing and security, piloting aircraft, care, nursing, and so on.

However, humanity in the 21st century lives in a strange case of an overabundance of skills. Even as we speak in the western world, vast numbers of highly trained people do not apply their abilities in real life but use them in virtual worlds. Malcolm Gladwell's 10k hour principle means that after 10k hours of doing something, you will likely be a master at it. And millions around the world have played much more than 10k hours in games and sims.

If only these skills could be harvested and focused on real-life problems.

Let's look at the construction worker gap problem.

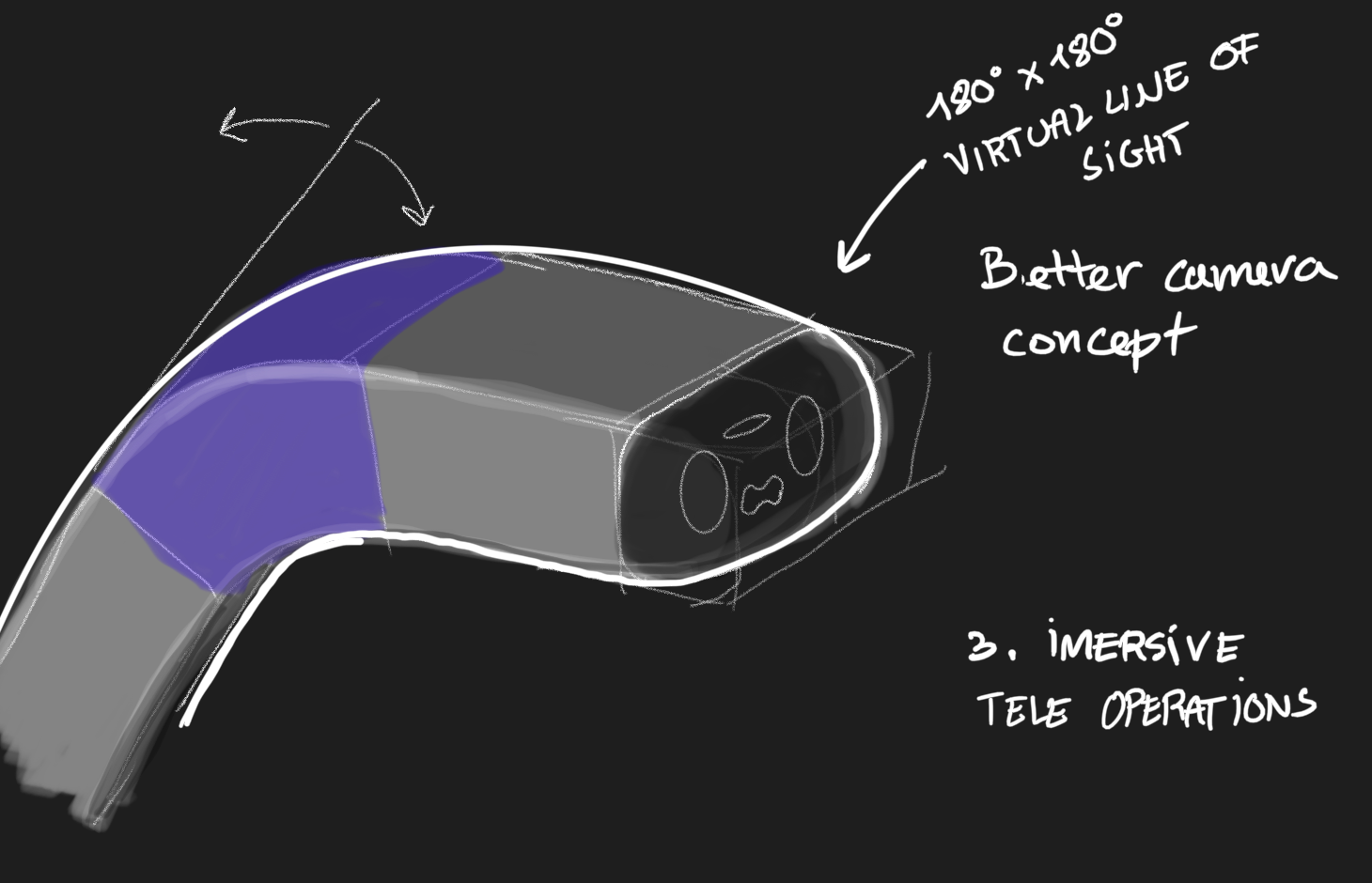

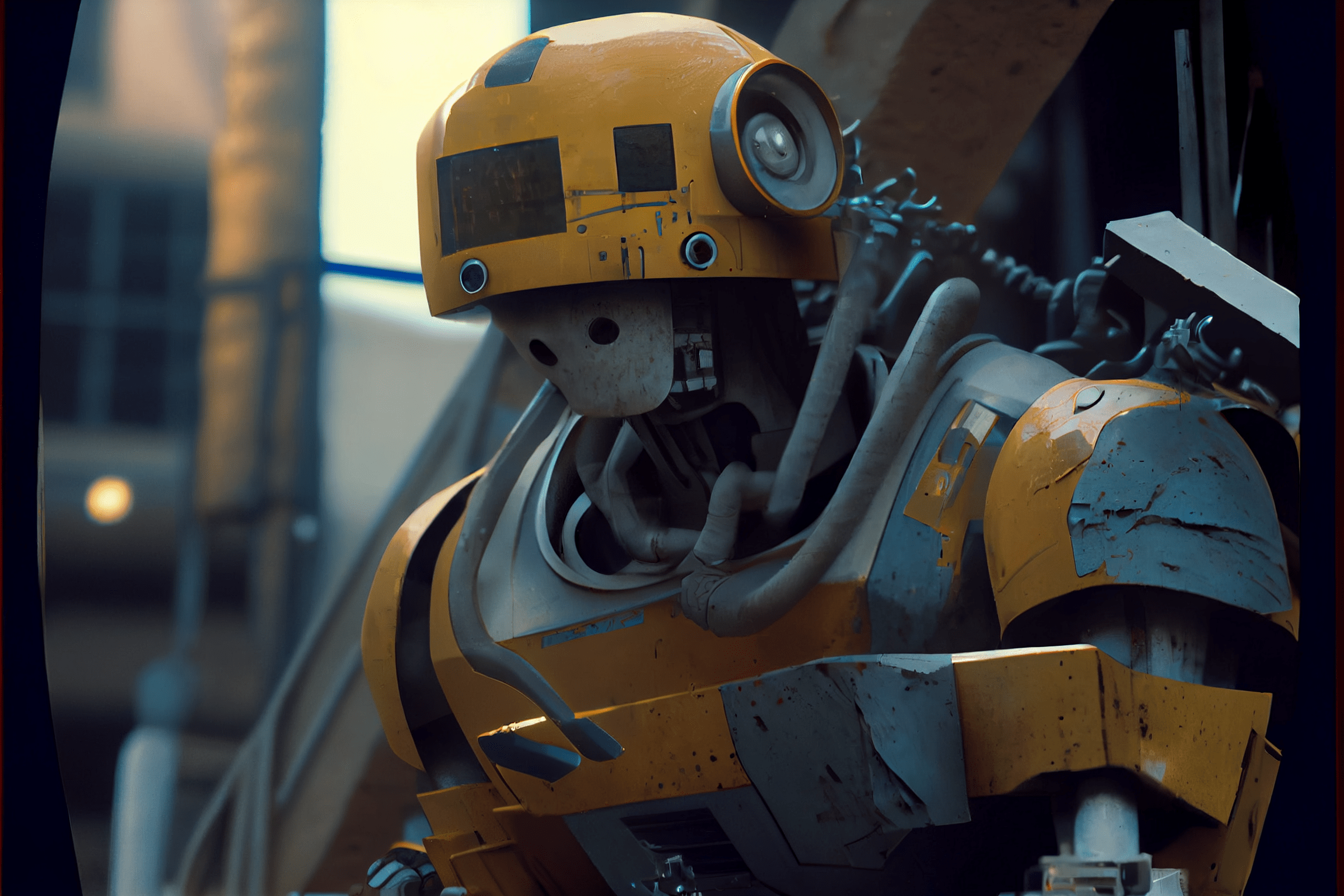

What if we could have an immersive virtual environment where people would be building in real life? Here's what you would need:

- Players would need a high bandwidth connection (which people already have to play their multiplayer games).

- They would need interfaces (such as Virtual Reality controls).

- They would need a physical presence on the construction site.

Of course, the first two requirements are already here. What's missing is number 3. Where could we start developing point 3? In a way, this type of solution has already been worked on in the past, but in an entirely different field: surgery.

Companies like Intuitive, with their DaVinci robot, have performed remote surgery on patients since the 90s! Intuitive even has already accomplished intercontinental surgery.

The design of the DaVinci probe is quite ingenious. Imagine if we could apply it to real-life construction scenarios. You would need to:

- Scale up the robot.

- Increase its power significantly.

- Make it compatible with existing construction machinery.

- Keep prices in the same range as existing construction machinery.

The robot would begin by having the same proportions as real humans. Giving it Human-sized arms and hands would make it compatible with existing construction sites, tools, and conditions.

The timeline would likely go as follows:

- The robot would perform on-site construction being piloted by an expert nearby.

- Access to the robot remotely would be developed so that experts could pilot it in remote and dangerous locations.

- Opening access to a play-to-earn marketplace, where anyone could sell their hours of operating the robot in exchange for actual earnings. After 10k hours of playing, anyone online would likely be an expert in building homes, high-rises, overpasses, underwater ducts, etc.

Instead of risking injury and death on construction sites, individuals could operate the robots from the safety of their own homes. It would also provide a new way for individuals to use their skills and passion for gaming to earn a living.

Implementation of this solution would require a partnership between startups and existing construction companies. Startups would need to work on developing and scaling the robots, while construction companies would need to provide the necessary funding and resources to make it a reality. Additionally, both parties would need to work together to develop the essential training and certification programs to ensure that individuals operating the robots are adequately trained and qualified. This could be done using virtual simulations of the robot.

In terms of business models:

- Primary monetization through a play-to-earn marketplace, where individuals could sell their hours of operating the robots for actual earnings.

- Additionally, construction companies could charge for using the robots, potentially at a lower rate than traditional construction labor.

From a financial perspective, this solution has the potential to save construction companies significant amounts of money in labor costs. It would also provide a new revenue stream for startups and individuals operating the robots.

Additionally, it would increase the efficiency and cost-effectiveness of construction projects, potentially resulting in higher profits for companies.

The path to complete automation

Eventually, the robot would learn from its human pilots and operate autonomously, allowing for even more efficient and cost-effective construction.Working in unpredictable environments is a very complex task to train robotic AIs. By copying humans, the learning speeds of these bots would grow exponentially.

Before AI for construction is fully formed Avatar bots can be deployed, and not only dwell in construction sites but especially in dangerous environments where human level skills are needed.

However the question remains: is it worth developing these avatars at all, as they will be unnecessary when automated construction robots are developed?

In any case, the construction worker gap problem is a pressing issue, and the solution could be to harness the skills and passion of gamers and apply them to real-life situations. By partnering with startups and existing construction companies, this type of solutions can become a reality, providing a new way for individuals to earn a living and continuously solve worker gaps.

Examples of companies working in construction robots

| Company Name | Description | Products | Country |

| ABB Robotics | One of the world’s leading robotics and machine automation suppliers. | N/A | Switzerland |

| Advanced Construction Robotics | World-leading innovator of autonomous robotic equipment. | Tybot, the autonomous rebar-tying robot and IronBot | USA |

| Align Robotics | An Australian robotics company established in 2017. | AutoMARK and TerraMARK | Australia |

| ANYbotics AG | Serves industrial operators with automated robotic inspections to support their efforts in monitoring and maintaining their plants. | ANYmal robot | Switzerland |

| Baubot GmbH | Develops mobile robots that can drive through doors, climb stairs, and use elevators. | BAUBOT MRS5 and BAUBOT MRS12 | Austria |

| Bimprinter | Develops full robotic high definition plotters for tracing at laser millimeter accuracy. | BIMPRINTER® | Belgium |

| Blue Ocean Robotics | Develops, produces, and sells professional service robots primarily in healthcare, hospitality, construction and agriculture. | UVD Robots, GoBe Robots, PTR Robots, etc. | Denmark |

| Boston Dynamics | Develops mobile robot designed for sensing, inspection, and remote operation. | SPOT | USA |

| Brokk AB | Produces electric demolition robots with a three-part arm system and powerful attachments. | Brokk 110, Brokk 180, and Brokk 280 | Sweden |

| Built Robotics | Develops autonomous construction equipment technology. | N/A | USA |

| Conjet AB | Specializes in hydrodemolition equipment and robotic solutions. | Conjet robots | Sweden |

| Fastbrick Robotics | Develops robotic bricklaying technology. | Hadrian X | Australia |

| Fetch Robotics | Develops and manufactures collaborative robots for warehouse automation. | Fetch and Freight robots | USA |

| Gomtec GmbH | Develops and produces mobile robots for construction sites. | Gomtec robots | Germany |

| KUKA AG | One of the world's leading suppliers of robots and automation systems. | KUKA robots | Germany |

| Manitou Group | Produces construction equipment and specializes in telehandler technology. | Manitou telehandlers with robotic arm attachments | France |

| RCT | Provides automation and remote control solutions for mobile equipment in the mining, construction, and aggregates industries. | RCT products | Australia |

| RoboTerra Inc. | Develops and sells modular robotic construction systems for various industries. | RoboTerra robots | USA |

| Trimble Inc. | A provider of advanced positioning solutions for construction, surveying, and agriculture. | Trimble robots and autonomous vehicles | USA |

| Company Name | Description | Products | Country |

| Topcon Positioning Systems | Provider of advanced positioning technology for construction, surveying, and agriculture. | Topcon robots and autonomous vehicles | Japan |

| UNIBO Robots | Develops modular, multi-purpose robots for various industries, including construction. | UNIBO robots | Italy |

| Vetropack Group | Produces glass packaging for the food and beverage industry, and specializes in automation and robotic technology. | Vetropack robots | Switzerland |

| VTT Technical Research Centre of Finland | A multidisciplinary research organization that specializes in developing and applying advanced technologies for various industries, including construction. | VTT robots and autonomous vehicles | Finland |

| Yaskawa Europe GmbH | A leading supplier of robotics and automation systems for various industries, including construction. | Yaskawa robots | Germany |

| ZenRobotics | Develops and manufactures robotic systems for recycling and waste management, including construction waste. | ZenRobotics robots | Finland |

References

- Gladwell, M. (2008). Outliers: The Story of Success. Little, Brown and Company.

- Intuitive Surgical. (n.d.). Da Vinci Surgery. Retrieved from https://www.intuitive.com/en-us/products-and-services/da-vinci

- The National Safety Council. (n.d.). Construction and Extraction. Retrieved from https://www.nsc.org/workplace/safety-topics/work-to-zero/hazardous-situations/construction-and-installation

- The World Bank. (2019). The Future of Work in Construction. Retrieved from https://www.worldbank.org/en/publication/wdr2019

- America desperately needs 1 million more construction workers, CNN Business. Retrieved from https://edition.cnn.com/2021/07/08/economy/construction-worker-shortage/index.html

- Chen, Y., & Stropki, A. (2019). The Impact of Automation on Employment and Public Policy. Congressional Research Service.

- Wang, J., & Li, X. (2019). Robot for Construction Industry: A Literature Review. Journal of Construction Engineering and Management, 145(3).

- Scott, M. (2019). The Rise of Virtual Reality in Construction. Construction Executive.

- KPMG. (2019). The Impact of Robotics and AI on Construction and Building. Retrieved from https://assets.kpmg/content/dam/kpmg/pdf/2016/04/employees-an-endangered-species.pdf

- Liu, X., & Wu, W. (2018). Research Progress and Challenges of Teleoperation in Construction Industry. Automation in Construction, 91, 47-62.

- The International Labour Organization. (2018). Abusive Employment Practices in the Construction Industry. Retrieved from https://www.ilo.org/global/topics/forced-labour/publications/abusive-employment-practices-in-the-construction-industry/lang--en/index.html https://www.ilo.org/wcmsp5/groups/public/---ed_dialogue/---sector/documents/publication/wcms_416378.pdf

#playtoearn, #constructioninnovation, #roboticsinconstruction, #virtualconstruction, #constructiontechnology, #futureofconstruction, #constructionjobs, #constructionefficiency, #smartconstruction, #innovativebuilding, #constructionindustry

© João Montenegro, All rights reserved.